Description

What is a Manual Hydraumatic Retriever Tool?

What is a Manual Hydraumatic Retriever Tool?

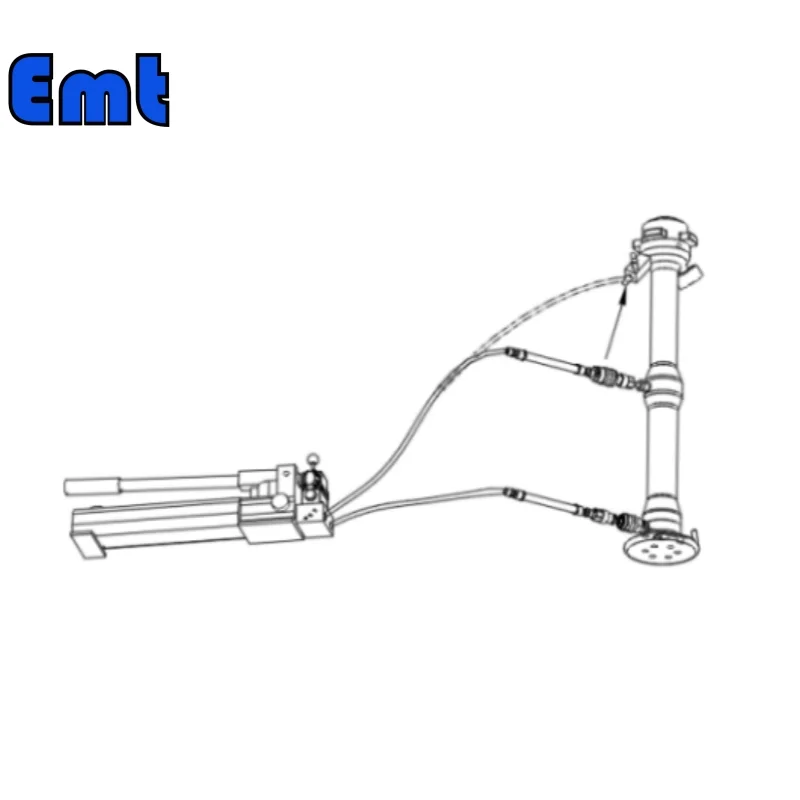

The Manual Hydrumatic Retriever Tool has revolutionized pipeline maintenance, especially in the demanding oil and gas industry. Its manual operation design ensures the safe handling of sensitive components, protecting pipelines and technicians. Durable materials and elastic engineering make the tool robust and durable in industrial applications. It uses a manual hydraulic system for precise control.

The adjustable jaws on the tool can hold pipes of various shapes and sizes. Therefore this versatility simplifies maintenance and reduces the need for multiple tools. Hand pumps allow operators to apply precise pressure to sensitive tasks, improving tool reliability and operational safety.

Faster completion of work and less manpower are the main benefits. Manual hydraulic recovery tools increase production efficiency, reduce costs, and are essential for effective pipeline management.

Definition of the Manual Hydraumatic Retriever Tool

The Manual Hydraumatic Retriever Tool is a key equipment for field technicians. It provides a safe way to handle pipe components, ensuring no harm to the component or operator. Designed for durability, the tool is designed with a focus on reliability and safety during operation. Its manual hydraulic system provides precise control, which is essential for delicate tasks.

The tool’s jaws can be adjusted to clamp different pipe sizes, enhancing its versatility. Technicians believe the tool can effectively maintain pipes, avoid damage,, and reduce the risk of injury. It’s an integral part of their toolbox, simplifying complex maintenance while maintaining safety standards complex maintenance while upholding safety standards.

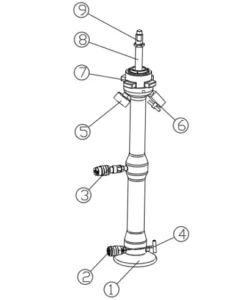

Components and Design

The tool’s design incorporates rugged materials to withstand industrial use, a hydraulic system manually operated via a hand pump, and jaws that adapt to various pipeline components.

| Number | Model | Name | Quality |

| 1 | EMT-HRTV-000-1 | Shell | 1 |

| 2 | EMT-HRTV-000-2 | Hydraulic hollow shaft | 1 |

| 3 | EMT-HRTV-000-3 | Hydraulic solid shaft | 1 |

| 4 | EMT-HRTV-000-4 | Hammer nut | 1 |

| 5 | EMT-HRTV-000-5 | Connecting nut (locking nut) | 1 |

| 6 | EMT-HRTV-000-6 | Hydraulic inlet valve body | 1 |

| 7 | EMT-HRTV-000-8 | Supporting wheel | 1 |

| 8 | EMT-HRTV-000-7 | Valve stem | 1 |

| 9 | DEEDLE VAVLE | Air release valve | 1 |

| 10 | Y60-1 | Pressure gage | 1 |

| 11 | EMT-HRTV-000-22 | Lock the seal ring | 1 |

| 12 | EMT-HRTV-000-19 | Hydraulic outlet quick connector | 1 |

| 13 | EMT-HRTV-000-16 | Hydraulic solid shaft locking nut | 1 |

| 14 | QF-11 | Hydraulic inlet quick connector | 1 |

| 15 | PTFE sealing ring | 1 | |

| 16 | PTFE sealing ring | 1 | |

| 17 | PTFE sealing ring | 1 | |

| 18 | PTFE sealing ring | 1 | |

| 19 | PTFE sealing ring | 1 | |

| 20 | O-ring | 1 | |

| 21 | Needle valve seal ring | 1 | |

| 22 | LS-8 | M8 inner hexagon bolt | 6 |

| 23 | SB-1 | Handwheel | 2 |

| 24 | M6 top wire | 6 | |

| 25 | O-ring | 1 | |

| 26 | O-ring | 1 | |

| 27 | O-ring | 1 | |

| 28 | EMT-HRTV-000-13 | Detent ring | 1 |

| 29 | Joint | 2 |

The Benefits of Using Manual Hydraumatic Retriever Tools

First, these tools are indispensable because they are efficient and reduce the time and manpower required for complex pipeline maintenance tasks. Second, they have cost-effectiveness and economic efficiency. This tool can reduce the need for extensive manual labor and shorten project time, resulting in significant cost savings for pipeline operations.

Manual Hydraumatic Retriever Tools in Action

The Manual Hydrumatic Retriever Tool is essential for the maintenance and repair of piping systems, especially in the demanding oil and gas industry. Technicians actively choose this manual mechanical device to ensure the safe handling of pipeline components, and effectively avoid damage to sensitive components.

Therefore it ensures the safety of workers. Its rugged construction with high-strength materials and manual hydraulic systems guarantees durability and life even in harsh industrial environments.

The tool’s thoughtful versatility design, including adjustable jaws, easily adapts to pipe elements of various sizes and shapes. It positions it as a universal solution for multiple maintenance tasks. In addition, the manual pump mechanism facilitates precise control of the hydraulic system, allowing the operator to apply the precise pressure required to manipulate the components.

As a result, the jaws of the tool can be securely attached to the assembly, allowing the assembly to be carefully inserted or removed from the pipe.

Conclusion

This practical pipeline maintenance method not only improves work efficiency but also greatly reduces labor costs. As a result, projects that once required a lot of manpower can now be completed faster, guaranteed to meet deadlines, and with minimal downtime. As a result, manual hydraulic recovery tools become a vital asset for contemporary piping operations, cleverly combining safety, precision, and cost-effectiveness into a single compact package.

What is a Manual Hydraumatic Retriever Tool?

What is a Manual Hydraumatic Retriever Tool?

Reviews

There are no reviews yet.