Description

What is “Fixed Type Injection” in Quill?

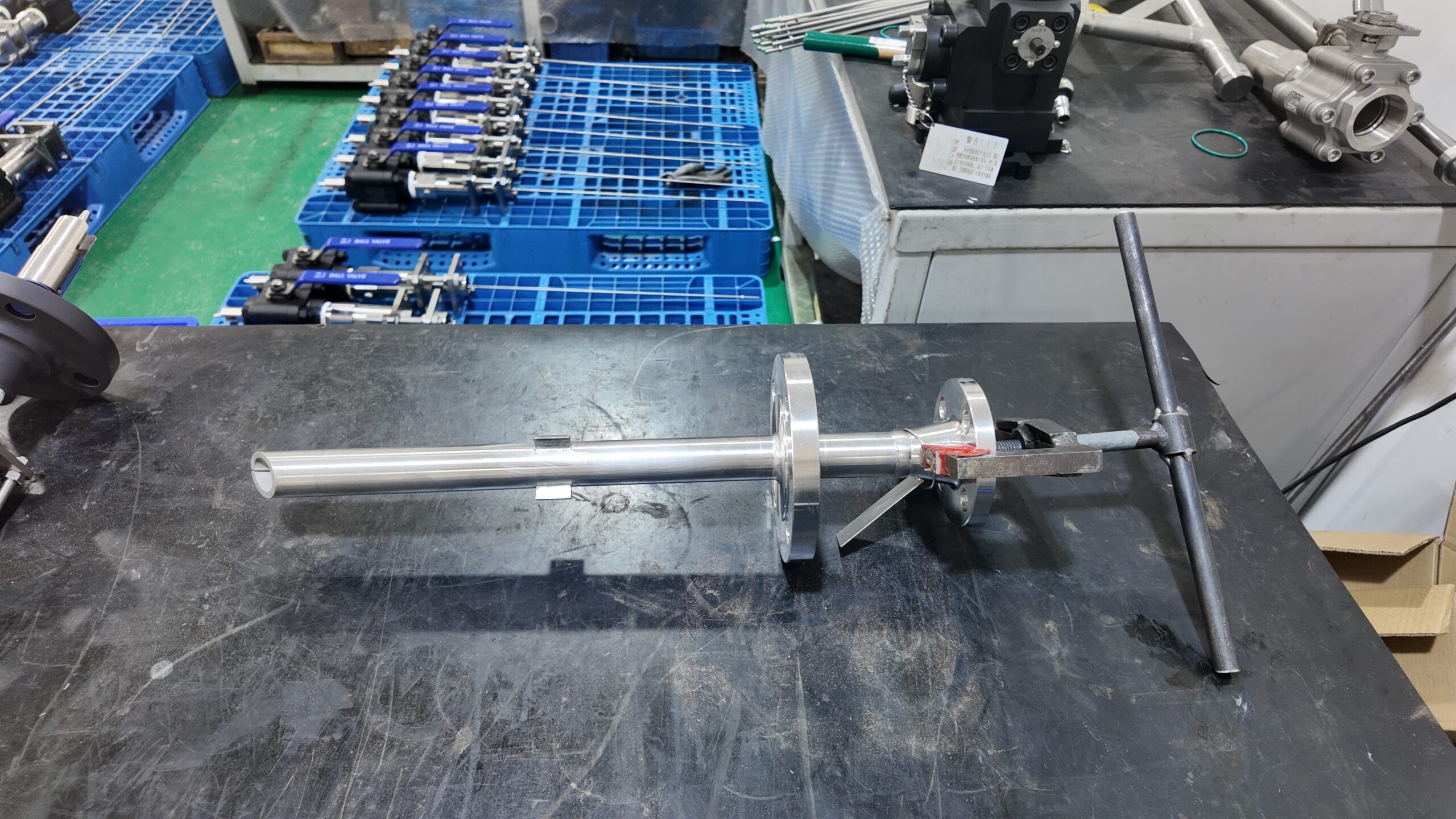

The Fixed Type Chemical Injection Quill is a precision-engineered device designed for the safe and efficient introduction of corrosive or reactive chemicals directly into process pipelines. Unlike traditional quills, which may cause erosion or uneven dispersion, this fixed type quill ensures uniform chemical distribution at the pipeline’s center—minimizing the risk of wall channeling, corrosion, and process inefficiencies.

Constructed from high-performance, corrosion-resistant materials such as 316 Stainless Steel, Hastelloy C-276, PVC, or Kynar, the quill is built for long-term durability in challenging industrial environments. It features an integrated spring-loaded check valve to prevent backflow when the system is offline, ensuring operational safety and system integrity.

The design incorporates a tapered stinger to reduce the effects of vortex shedding, cavitation, and potential quill fatigue—issues commonly associated with older, tube-style injection systems. Each unit is custom-designed to meet specific process conditions, adhering to ASME standards for strength, vibration resistance, and secure pipe attachment.

Optimized for continuous operation, the Fixed Type Injection Quill is ideal for applications requiring reliable and consistent dosing of chemicals such as corrosion inhibitors, biocides, or process additives. It is widely used across industries including oil & gas, petrochemicals, and water treatment, where system performance and safety are critical.

What Are Injection Quills?

Injection quills are specialized tube-like devices designed to introduce secondary fluids—such as catalysts, additives, or chemicals—into a pipeline or static mixer. These quills ensure uniform dispersion of injected materials into the main flow stream, enhancing the mixing process and improving final product consistency.

Their primary purpose is to inject chemicals or additives at precise locations within a static mixer or pipeline, ensuring even distribution and preventing common issues like dead zones, channeling, or erosion of pipeline walls.

Design and Functionality of Injection Quills

The design of an injection quill is critical for its performance. Typically constructed from corrosion-resistant materials like 316 stainless steel, Hastelloy C-276, PVC, or Kynar, injection quills are built to withstand corrosive chemicals and high-pressure environments.

Key Design Features:

- Customizable length and diameter to match specific process requirements

- Tapered tips to minimize pressure drop and turbulence

- Spring-loaded check valves to prevent backflow in case of shutdown

- Secure mounting systems to resist vibration and flow-induced forces

The quill’s internal geometry is engineered to optimize flow patterns, ensuring that injected materials integrate seamlessly into the primary flow stream.

Applications Across Industries

Chemical Industry

Injection quills are used to introduce corrosion inhibitors, catalysts, or pH control agents into reaction streams. Their precision helps maintain optimal reaction rates and prevent pipe degradation.

Food and Beverage

In this sector, injection quills facilitate the addition of flavorings, preservatives, and colorants. Their ability to deliver consistent dosing ensures uniform taste and appearance across batches.

Pharmaceuticals

Here, precision is paramount. Injection quills help blend active pharmaceutical ingredients (APIs) with excipients, ensuring that medications meet strict regulatory standards for potency and uniformity.

Advantages of Using Injection Quills

Improved Mixing Efficiency

By injecting materials at optimal points, quills enhance homogeneity in the mixing process, resulting in better product quality and reduced waste.

Energy Savings

Injection quills in static mixers help maintain low-pressure drop characteristics, reducing the need for high-energy pumps or agitators.

Operational Flexibility

Manufacturers can easily adjust production formulas without halting operations, thanks to the flexible design of injection quills.

Enhanced Safety and Durability

With integrated check valves and corrosion-resistant materials, modern quills are built for long-term, safe operation even in harsh environments.

Installation and Maintenance Best Practices

Proper installation is essential for maximizing the performance of injection quills:

- Safety First: Always wear PPE and ensure the system is depressurized before installation.

- Site Preparation: Identify the correct injection point and flush the pipeline.

- Leak Prevention: Use Teflon tape or sealant, and secure connections without over-tightening.

- System Testing: After installation, test for leaks and ensure proper flow.

- Ongoing Maintenance: Regular inspections prevent blockages and extend equipment life.

Future Trends in Injection Quill Technology

As industries move toward smart manufacturing and sustainability, injection quill technology is evolving rapidly.

Material Innovations

New polymer composites and advanced alloys are improving durability and resistance to wear and corrosion.

Smart Monitoring

The integration of IoT sensors could enable real-time monitoring of injection rates, pressure changes, and flow dynamics—helping operators make data-driven decisions.

Sustainability

By allowing precise chemical dosing, quills reduce waste and overuse of additives—supporting sustainable manufacturing goals and reducing operational costs.

Conclusion

Injection quills are indispensable tools in modern process industries, playing a vital role in enhancing the efficiency and precision of static mixing systems. Their ability to accurately inject and distribute fluids improves product quality, energy efficiency, and process flexibility. As technology continues to evolve, injection quills are poised to become even more reliable, intelligent, and sustainable—solidifying their place in the future of industrial mixing.

Whether you’re in chemical manufacturing, food production, or pharmaceuticals, incorporating high-quality injection quills into your static mixer setup can significantly improve process performance and product outcomes.

Reviews

There are no reviews yet.