Description

I. Introduction

Quick Open Closures, or QOCs, are vital parts that are employed extensively across a wide range of industries to enable secure, effective, and quick access to the interior of a pressure vessel. These mechanical mechanisms, which are engineered for maximum performance, are made to safely and easily close off high-pressure chambers when not in use.

Their main duty is to protect the integrity and safety of pressure vessels, which are frequently subjected to harsh conditions. Examples include pipelines, tanks, and reactors. QOC significantly reduces operating downtime by streamlining the operations of inspection, maintenance, and cleaning by providing a safe yet accessible seal.

QOC is widely used in many fields thanks to its adaptability and effectiveness. One of the most important is the oil and gas sector, where they are essential to the secure operation of storage tanks and pipelines. They play a significant role in the reactor and separator needs of the petrochemical and chemical industries. Similar to this, QOCs are essential for upholding high standards of safety and cleanliness in the pharmaceutical, food processing, and water treatment industries.

In summary, QOC acts as a crucial gateway that combines safety, efficiency, and accessibility between operators and the high-pressure conditions within their equipment.

II. Design and Mechanics of Quick Open Closures

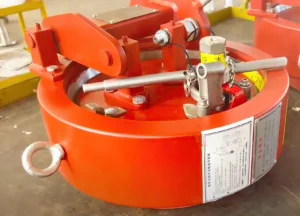

QOCs are cleverly made to strike a balance between the needs of security, effectiveness, and usability. The closure door, the seal, and the locking mechanism are typically their three main parts.

The Quick Open Closure’s closure door serves as its main structural component. It is hinged or directly attached to the pressure vessel and is robustly built to handle high pressure. The seal and locking mechanism are frequently accommodated by a specific shape built into the door’s construction.

The seal is intended to establish a pressure-tight fit between the closure door and the pressure vessel. It is often made of robust elastomeric materials. Some QOCs use seals with unusual forms to take temperature and pressure fluctuations into consideration, ensuring a trustworthy seal in a range of situations.

The characteristic that lends Quick Open Closures their name is the locking mechanism. Simple threaded or bolted designs or more intricate quick-release systems can all be used for this mechanism. But most locks are designed with the intention of being quick and simple to unlock when necessary while still being secure. With this design, the pressure vessel may be accessed quickly for maintenance, cleaning, or inspection.

Depending on the particular needs of the application, Quick Open Closures are frequently manufactured from high-strength, corrosion-resistant metals like stainless steel, carbon steel, or alloy alloys. Because the material must endure the pressure, temperature, and potential corrosive effects of the contents inside the pressure vessel, choosing the right material is essential.

Quick Open Closures, in their simplest form, are expertly crafted tools that include a variety of design characteristics to offer a workable and efficient solution for accessing high-pressure vessels in a variety of sectors.

III. Advantages of Quick Open Closures

Quick Open Closures’ unique functionality and design have several benefits, especially in terms of longevity, operational effectiveness, and safety.

Security: Quick Open Closures are made with security as their first priority. Due to the fact that these devices can resist high-pressure conditions, there is less chance of an unintentional discharge or leak, both of which could pose serious safety risks. In order to prevent accidental opening under pressure, several versions also have safety features like pressure warning signs or fail-safe locking mechanisms. These features provide an extra degree of protection for users.

Operational Efficiency: Quick Open Closures have a considerable positive impact on improving operational efficiency. They dramatically cut down on the amount of time needed for inspections, maintenance, and cleaning processes because of their design, which enables quick access to pressure vessel interiors. In fields where operational continuity is essential, this efficiency reduces downtime, boosting output. Cost reductions and an improvement in overall operational performance may follow from this.

Durability and Longevity: Quick Open Closures are made to withstand tough circumstances and continuous use since they are made of high-strength, corrosion-resistant materials like stainless steel or other strong alloys. This robustness guarantees a longer operational lifespan, which, over time, lowers replacement costs. Additionally, the design of these closures frequently makes it possible to replace parts like seals with ease, increasing their lifespan and offering companies a cost-effective alternative.

IV. Quick Open Closures in Different Industries

Quick Open Closures can be used in a variety of sectors since they are adaptive and versatile. Let’s examine their function in a number of important sectors in more detail:

Oil and Gas Industry: Quick Open Closures are widely utilized in pipelines, storage tanks, and pressure vessels in the oil and gas industry. For these systems, they offer dependable and secure sealing, assuring the containment and safe transportation of oil and gas products. In a sector where operating efficiency is crucial, the quick-opening feature enables quick access for maintenance and inspections, greatly decreasing downtime. Their durable construction can also endure the challenging circumstances frequently found in oil and gas operations, improving safety and dependability.

Chemical Industry: Quick Open Closures are widely employed in reactors, separators, and other high-pressure containers in the chemical industry. Thanks to their durable construction and top-notch materials, they guarantee the secure containment of caustic and volatile compounds. These closures make it easy to conduct routine inspections and maintenance, which are crucial for maintaining the continuous safety and effectiveness of chemical processes.

Other Industries: Quick Open Closures are used in a variety of industries besides those related to the oil, gas, and chemical industries. They are employed in pressure vessels in the pharmaceutical sector to provide dependable confinement and ensure a sterile environment during manufacturing and storage. Quick-open closures make it simple to clean and sanitize vessels during food processing, helping to maintain high levels of cleanliness. They are used in the water treatment industry as well, where they offer safe and convenient access for the upkeep of high-pressure filtration and treatment systems.

V. Future of Quick Open Closures

Quick Open Closures are anticipated to undergo substantial changes in the future as industries continue to change and technology develops. Here are some prospective developments and new trends to watch:

Potential Evolution: It’s possible that Quick Open Closures’ core design won’t change significantly throughout the years. Even quicker opening mechanisms, more durable sealing materials, and the incorporation of smart technologies, however, could be considered improvements. It is anticipated that sensors will be integrated to track seal integrity, pressure levels, and other important factors. Enabling predictive maintenance would further improve operating effectiveness and safety.

Emerging Trends and Innovations: Quick Open Closures may be incorporated into the Internet of Things (IoT) networks as industries transition to digitalization and Industry 4.0. Enabling real-time monitoring and control would make it possible to anticipate probable problems, plan maintenance, and increase productivity by lowering downtime.

The greater emphasis on sustainability is another trend. Quick-Open Closures might be created using more eco-friendly materials or to be more easily recycled at the end of their useful lives. Additionally, employing more environmentally friendly production techniques could further lessen the impact.

Impact on Use: The use of Quick Open Closures may be significantly impacted by these developments. The danger of accidents may be decreased, and operational effectiveness may be increased, with improved safety features and predictive maintenance capabilities. IoT integration may improve control and minimize unplanned outages. The emphasis on sustainability, meanwhile, might make Quick Open Closures even more alluring to sectors looking to lessen their environmental impact.

VI. Characteristics

Characteristics | ||||

Design Pressure | 1.6MPa-30MPa | |||

Corrosion Allowance | 2mm | |||

Seismic Fortification Intensity | 7 Degrees | |||

Work Medium | Oil, Natural gas, Water and ore pulp, etc. | |||

Opening Time | Within 60s less than 200N | |||

Opening Type | Vertical or Horizontal | |||

VII. Conclusion

We have learned how important Quick Open Closures are and how versatile they are via this investigation of several sectors. These devices have proven their value by ensuring safety, improving operating efficiency, and providing exceptional durability in a variety of industries, including the oil and gas sector, the chemical industry, pharmaceuticals, food processing, and more.

The distinctive design features of QOCs, which enable them to endure high-pressure conditions, their contribution to overall operating efficiency by reducing downtime, and their sturdy construction, which ensures lifetime, are important points to keep in mind. Additionally, their use in a variety of industries highlights their adaptability and agility to various operational requirements.

Future prospects for Quick Open Closures appear bright. These devices are positioned to not only maintain their relevance but also adapt in step with the shifting industrial landscape thanks to potential improvements in smart technology integration, predictive maintenance capabilities, and a rising emphasis on sustainability.

Reviews

There are no reviews yet.