Description

I. Introduction

Corrosion is a common problem in many industries, especially those that use pipelines. It can cause materials to wear down and can impact the safety and productivity of operations. Because of this, it’s important to keep an eye on and manage corrosion. One of the best ways to do this is by using Corrosion Monitoring Probes. These helpful tools are key in checking and managing how much corrosion is happening, and they give important information that can help stop potential issues and keep our systems working well. This essay will give more details about Corrosion Monitoring Probes, including how to install them, how they work, and why they’re important in our industries today.

II. What are Corrosion Monitoring Probes?

II. What are Corrosion Monitoring Probes?

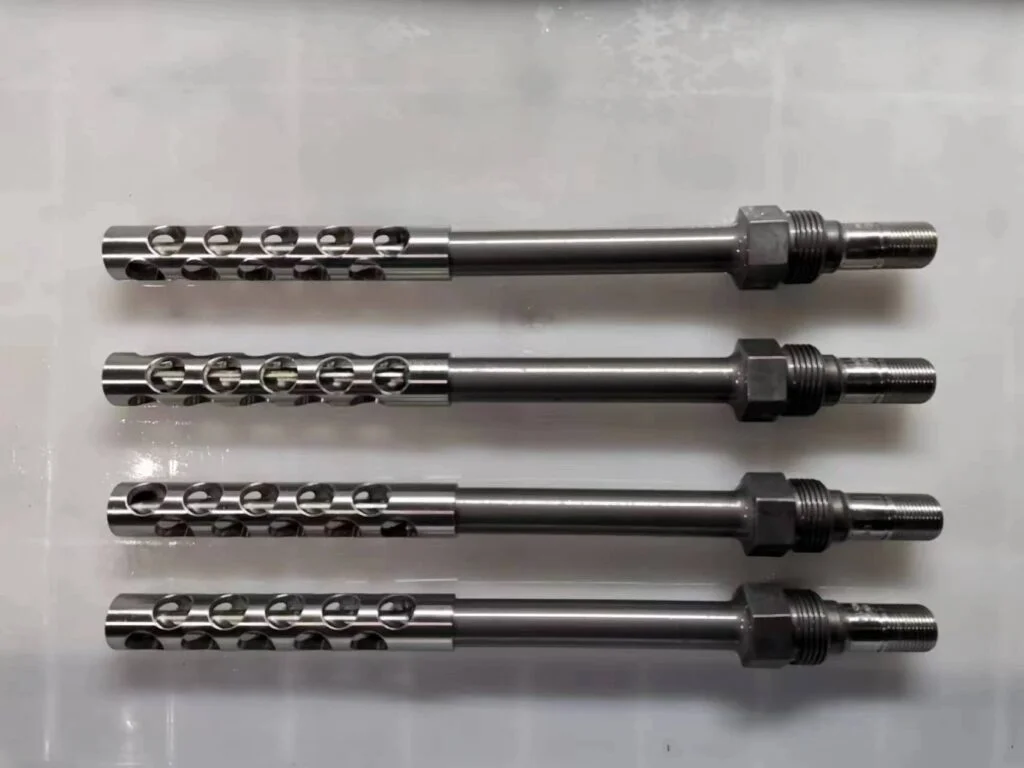

Corrosion Monitoring Probes are specialized devices designed to measure and track the rate of corrosion within a system, typically pipelines in various industries. These probes provide valuable data that can help in making informed decisions about system maintenance and corrosion prevention strategies.

There are several types of Corrosion Monitoring Probes, each with a specific purpose and application. Some of the common types include:

- Electrical Resistance Probes: These measure the increase in electrical resistance caused by metal loss due to corrosion. They are often used for online monitoring and provide real-time data.

- Linear Polarization Resistance Probes: These probes offer a non-destructive way of measuring corrosion rates. They are useful for providing quick feedback about changes in the corrosion rate.

- Galvanic Probes: These probes measure the natural potential difference between two different metals. They are often used in environments where the corrosion rate is relatively uniform.

- Weight Loss Coupons: While not a traditional probe, these are pieces of metal that are exposed to the corrosive environment for a set period, then removed and analyzed for weight loss to determine the corrosion rate.

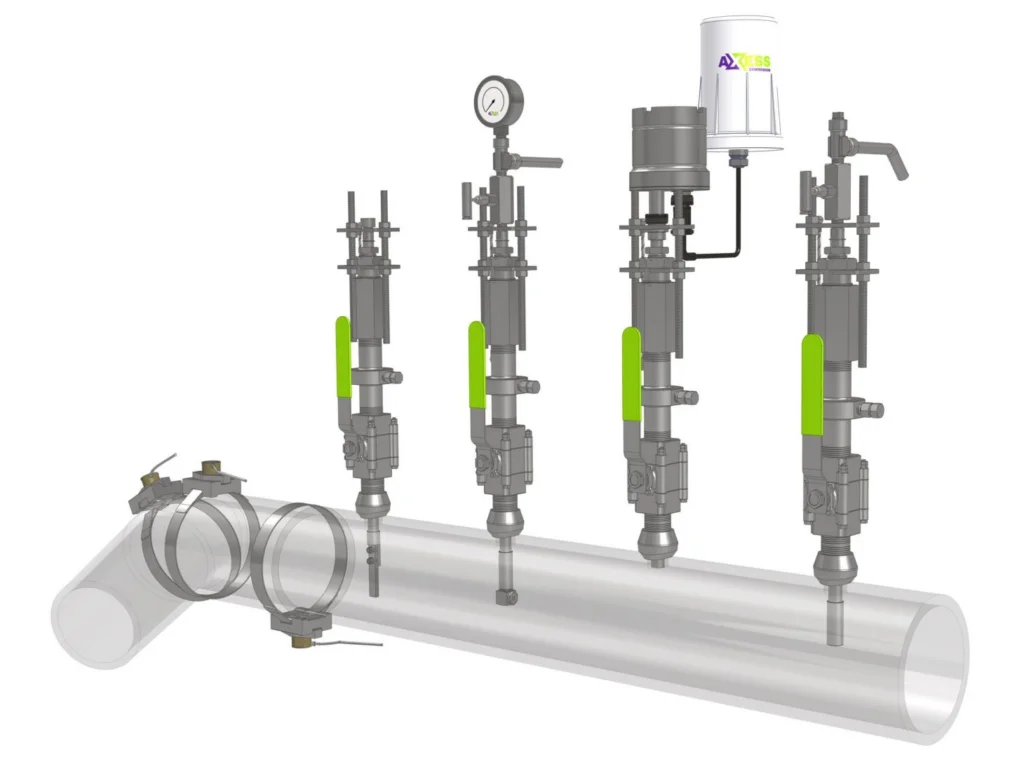

III. Corrosion Probe Installation

- Select the Appropriate Probe: The first step is to choose the right probe based on the system’s requirements and the type of corrosion that you want to monitor.

- Choose the Installation Site: Select a site that’s representative of the whole system and where corrosion is likely to occur.

- Prepare the Installation Site: This could involve drilling a hole if the system is a pipeline, or preparing a mounting site if the system is a tank or vessel.

- Install the Probe Holder: The probe holder is typically mounted first. It’s designed to hold the probe in place and usually has a seal to prevent leaks.

- Install the Probe: Insert the probe into the holder. Make sure it’s properly seated and secure.

- Connect the Probe to the Monitoring System: Once the probe is installed, it needs to be connected to the monitoring system. This could involve running wires, or in the case of wireless probes, ensuring it’s properly paired with the monitoring system.

- Calibrate the Probe: Before the probe can provide accurate readings, it needs to be calibrated. This involves comparing the probe’s readings to a known standard and adjusting as necessary.

- Check for Leaks and Other Issues: After the probe is installed and calibrated, check for any leaks around the probe holder. Make sure the probe is providing readings to the monitoring system.

- Begin Monitoring: Once everything is installed and checked, you can begin monitoring for corrosion.

Factors to Consider During Corrosion Probe Installation

- Probe Type: Different types of probes are designed for different applications and operational conditions. For instance, Electrical Resistance Probes are better suited for environments with high corrosion rates, whereas Linear Polarization Resistance Probes are more appropriate for environments with varying corrosion rates.

- Location of the Probe: The location where the probe is installed is crucial for accurate corrosion rate measurements. The probe should ideally be placed in a representative location where corrosion is expected or in critical areas where failure could have significant consequences.

- Environment and Operational Conditions: The conditions under which the probe will operate — including temperature, pressure, fluid velocity, and the type of corrosive agent — can greatly influence the type of probe used and the way it’s installed. For instance, high-temperature environments might require probes made of materials that can withstand such conditions.

- Accessibility: The probe should be installed in a location that’s easily accessible for maintenance, calibration, and data retrieval.

- Safety: Safety should always be a priority when installing probes. This includes considering factors like the pressure of the system, the potential for leaks, the probe’s compatibility with the system materials, and the potential hazards of the working environment.

- Data Collection Requirements: The frequency and type of data required will influence the choice of probe and its installation. For instance, if continuous real-time data is needed, you might opt for probes compatible with an online monitoring system.

IV. Corrosion Probe Working Principle

Corrosion Monitoring Probes work in different ways to keep an eye on how quickly corrosion is happening. It all depends on the type of probe. Here’s a simple explanation of how they work:

- Electrical Resistance Probes: These probes look at how electricity moves through a metal piece. As the metal corrodes, it gets thinner and electricity moves through it more slowly. By checking how much slower the electricity moves, we can tell how fast the metal is corroding.

- Linear Polarization Resistance (LPR) Probes: These probes put a little bit of voltage into the metal piece and then see how much the electric current changes. The amount of resistance to this change can tell us the corrosion rate. The good thing about LPR probes is that they give us quick feedback on the corrosion rate.

- Galvanic Probes: These probes use two different metals and measure the natural electric potential difference between them. This difference can tell us about the corrosion rate. Galvanic probes are best used in places where the corrosion happens at a steady rate.

- Weight Loss Coupons: These are not traditional probes but they work in a simple way. A piece of metal, known as a coupon, is left in the corrosive environment for a certain time. After that time, it’s taken out, cleaned, and weighed. The change in weight shows how much material was lost to corrosion, and this can tell us the corrosion rate.

V. Benefits and Limitations of Corrosion Monitoring Probes

Benefits of Corrosion Monitoring Probes

- Early Detection: Probes can detect corrosion at an early stage, even before it’s visible to the naked eye. This allows for prompt remedial action before the corrosion escalates to a critical level.

- Prevention of Failures: By providing early warnings, probes can help prevent catastrophic failures such as pipeline leaks or ruptures, which can have severe safety and environmental implications.

- Cost Savings: Probes can help save costs in the long run by identifying corrosion early, allowing for preventative maintenance rather than more expensive repairs or replacements after a failure has occurred.

- Life Extension of Assets: Regular monitoring can help extend the life of assets by ensuring that corrosion is managed effectively.

- Data for Corrosion Management Strategies: The data from corrosion probes can help in developing effective corrosion management strategies and in assessing the effectiveness of current corrosion control measures.

Limitations of Corrosion Monitoring Probes

- Representativeness: The data obtained from a probe only represents the specific location where the probe is installed. If the corrosion is not uniform across the system, the probe might not give an accurate picture of the overall corrosion rate.

- Interference: Some probes could be affected by other factors in the system, such as changes in fluid velocity or temperature, which can interfere with the readings.

- Installation Challenges: Installation of probes can be complex, especially in high-pressure or high-temperature systems, and might require system shutdown.

- Maintenance: Probes require regular maintenance and calibration to ensure accurate readings. If not maintained properly, the data obtained could be misleading.

- Cost: Initial setup and maintenance of a corrosion monitoring system can be costly, though these costs are often outweighed by the potential cost of a failure.

VI. Conclusion

Corrosion Monitoring Probes are really important in lots of industries like oil and gas, chemical production, and water treatment. They’re important because they can spot corrosion early, stopping bigger problems before they happen. This can keep people safe, protect the environment, and also save money. By having up-to-date information on how fast corrosion is happening, these probes let us step in and fix things before they get worse. This can mean equipment lasts longer and costs less to look after. The information from these probes also helps us make plans to manage corrosion effectively, adding to their usefulness.

To wrap up, Corrosion Monitoring Probes are really useful tools for managing and preventing corrosion. Even though there are some challenges, like making sure the data represents the whole system and keeping the probes working correctly, the benefits usually outweigh these issues. The secret to using these probes effectively is to understand how they work, install them properly, and make sense of the data they provide in relation to the specific system and how it operates. By doing this, industries can use these probes not just to keep an eye on corrosion, but also to reduce its impacts. This can make their operations more efficient, safer, and more sustainable.

II. What are Corrosion Monitoring Probes?

II. What are Corrosion Monitoring Probes?

Reviews

There are no reviews yet.