Description

What is a corrosion coupon?

A corrosion coupon is a simple, yet effective, tool used in the monitoring and analysis of corrosion rates within a pipeline, tank, or any other metallic structure. It is a small, standardized, rectangular piece of metal. Besides, there are circular coupons too.

Corrosion coupons are standard metal test pieces that are suspended in a test container or placed directly in the site to monitor heat exchangers or test pipelines. Their purpose is to monitor or evaluate the corrosion condition of a cooling water system. Typically, metal specimens are pre-treated and weighed before being placed into the testing system for a certain period (such as 30 to 90 days), after which they are removed for examination of the corrosion condition. They are then cleaned and weighed to determine the annual corrosion rate (measured in mils per year, where 1 mpy = 0.0254mm/a), the type of corrosion, and the depth of pitting corrosion, among other things. The data obtained from the metal coupons is influenced by not only the corrosive medium but also factors such as coupon surface treatment, placement location, exposure duration, and metallurgical methods of the sample.

The installation of a corrosion coupon

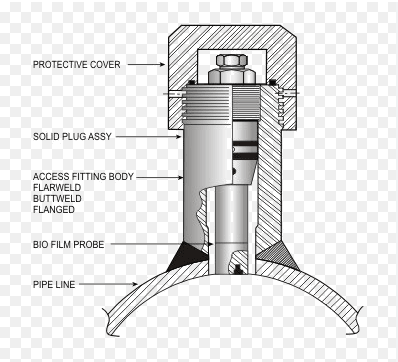

The installation of a corrosion coupon within a system is a methodical process. Typically, the coupon is inserted into the pipeline using a holder or probe, which is installed via a flange or welding process. This installation is not random but is carried out strategically, with the coupon usually positioned in the lower third of the pipeline. The insertion depth is often two-thirds of the pipeline’s diameter, aligning the coupon within the most active corrosion zone to accurately represent the corrosive conditions within the system.

However, the exact placement of the coupon may vary depending on the specifics of the pipeline, including its size, flow characteristics, and the nature of the product it carries. Careful consideration is given to these factors to ensure the coupon is exposed to the same conditions as the system internals.

It’s crucial to note that while the coupon should be inserted deep enough to accurately gauge corrosion rates, it should not touch the bottom of the pipeline. This careful balance in placement ensures the coupon can effectively monitor the corrosive conditions without interfering with the system’s operation.

What is an AC DC corrosion coupon?

An AC/DC Corrosion Coupon is a specialized type of corrosion coupon specifically designed to monitor and analyze the impact of both Alternating Current (AC) and Direct Current (DC) on corrosion rates within a pipeline or other metallic structure.

Corrosion in pipelines can be influenced by various factors, including the presence of electrical currents. Stray electrical currents, both AC and DC, can exacerbate corrosion, leading to a phenomenon known as “electrolytic” or “electrochemical” corrosion.

A brief explanation of both:

- AC Corrosion: AC, or Alternating Current, corrosion can occur when a pipeline is in close proximity to high-voltage power lines. The AC from these power lines can be induced into the pipeline, leading to rapid corrosion at points where the current leaves the pipeline to return to the ground.

- DC Corrosion: DC, or Direct Current, corrosion can occur when a pipeline is exposed to stray DC currents. This can occur in pipelines that are located near DC-powered railways or due to improper grounding of cathodic protection systems.

How do corrosion coupons work?

Corrosion coupons work based on a simple principle: they are exposed to the same conditions within a pipeline, tank, or other system as the materials they represent, and the amount of corrosion they experience over a set period of time is used to calculate the corrosion rate within the system.

Access fittings for corrosion coupon

The EMT Access Fitting is engineered to facilitate Corrosion and Erosion monitoring in pressurized process environments. It allows for the safe insertion and removal of the monitoring device using specialist tools, eliminating the need for expensive shutdowns or temporary isolations. This Access Fitting is versatile enough to accommodate the insertion and removal of an array of Corrosion Coupons, Corrosion Probes, and Erosion Probes. Specific equipment can be provided as per request.

Corrosion coupon working principle

The corrosion evaluation method primarily used for coupons is the mass loss method. To obtain meaningful and measurable mass loss data, an extended exposure period may be necessary. For analysis and determination of the corrosion rate, the coupon must be removed from the plant or equipment (note: if the coupon is to be re-exposed, its removal and cleaning may affect the corrosion rate). These devices can only provide cumulative historical information. For example, after 12 months of exposure, stress corrosion cracking might be found on a coupon, but it’s impossible to determine when the crack began or what special conditions caused the onset and development of the crack. Importantly, the crack propagation rate cannot be accurately estimated because the start time of the crack is unknown. The cleaning, weighing, and microscopic inspection of coupons generally require a significant amount of labor. The use of coupons does not easily simulate the effects of wear corrosion and heat transfer on corrosion.

Why use corrosion coupons?

Corrosion coupons are used for several reasons, primarily for monitoring and managing the corrosion rates in industrial systems such as pipelines, tanks, and oil wells. Here are some key reasons why corrosion coupons are used:

- Predictive Maintenance: By regularly monitoring the corrosion rate using coupons, you can estimate the remaining life of your system. This allows you to schedule maintenance or replacement before a failure occurs.

- Evaluating Corrosion Control Measures: If you are using corrosion inhibitors or other corrosion control methods, you can use coupons to measure their effectiveness. If the corrosion rate decreases after implementing a control measure, this indicates that the control measure is effective.

- Identifying Corrosion Types: The physical appearance of a corroded coupon can give clues about the type of corrosion occurring. For example, pitting corrosion results in small holes in the coupon, while uniform corrosion leads to an overall thinning of the material.

- Cost-Effective Monitoring: Corrosion coupons are relatively inexpensive to produce and install, making them a cost-effective method for monitoring corrosion.

- Versatility: Coupons can be made from any metallic material, allowing them to be used in a wide range of environments and systems.

- Understanding Corrosion Mechanisms: Coupons can provide valuable data that help in understanding the corrosion mechanisms at play, and in turn, this understanding can inform the design of more effective corrosion control strategies.

Summary

In conclusion, corrosion coupons play a crucial role in monitoring and managing corrosion rates in various industrial systems. They offer a cost-effective and versatile method to assess the effectiveness of corrosion control measures, predict the lifespan of equipment, and identify corrosion types.

-600x600.jpg.webp)

Reviews

There are no reviews yet.