Description

Introduction

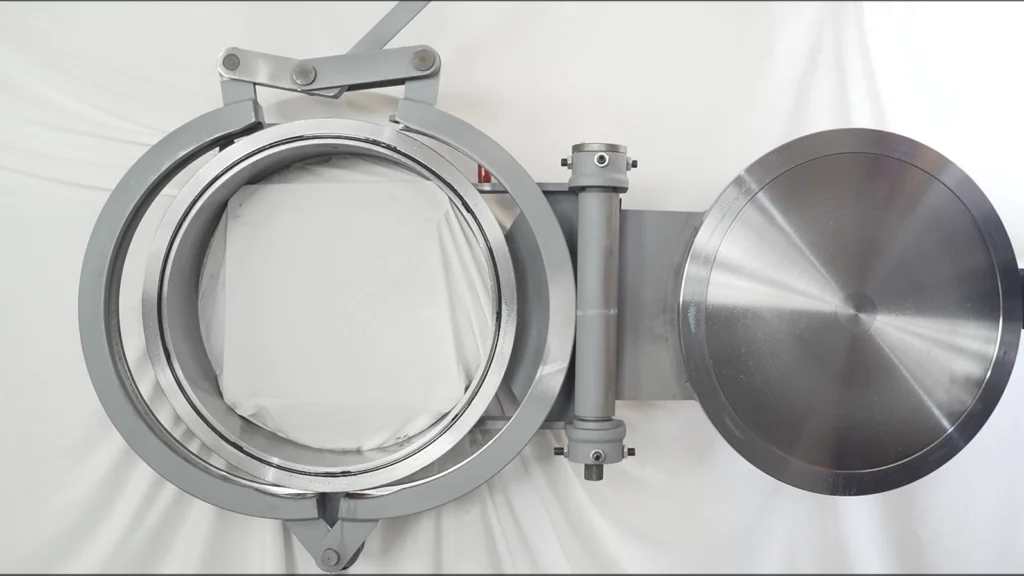

This article takes an exploratory dive into the realm of Quick Closures, specifically concentrating on Clamp Type Quick Opening Closures. These devices, critical in a myriad of industrial operations, are engineered with precision and safety in mind, playing a key role in efficient and secure pipeline management. Stay tuned as we delve into the intricacies of their design, functionality, and the benefits they bring to the table.

In summary, Clamp Type Quick Closures are expertly designed devices that provide quick and safe access to pipelines, therefore streamlining industrial processes, reducing risks, and improving overall operational efficiency.

Understanding Clamp Type Quick Closures

Clamp Type Quick Closures are specifically designed devices that play an integral role in ensuring fast, safe, and efficient access to pipelines and pressure vessels across various industrial applications. These closures are essential in the world of pipeline management, offering operators a way to swiftly and safely open and close the pipeline, simplifying maintenance and inspection processes.

These quick closures are versatile and are manufactured to cater to pipeline applications of various diameters, ranging from 2” to 48” (DN50 to DN1200). This adaptability makes them suitable for a wide range of pipeline sizes. They are built to the highest standards and certified to meet ASME B31.3/B31.4/B31.8/CSA Z662 Cat. I with a 0.5/0.6 design factor.

Clamp Type Quick Closures are characterized by their user-friendly design, featuring high-quality components strategically placed for easy access and operation. One of the key features of these closures is the large cross-section O-ring design. This design ensures a positive seal and offers protection from tools and debris. Another critical feature is a Pressure Alert Valve, designed to operate without the need for an additional O-ring, and is built according to UG-35.2 of ASME BPVC VIII Div. 1, thereby maintaining the highest safety standards.

These quick closures find their use in a wide array of industries that require regular pipeline or pressure vessel inspections, such as the oil and gas, petrochemical, and power generation sectors. Their speed, safety, and efficiency make them an indispensable tool for operators in these industries.

Even more, the versatility of Clamp Type Quick Closures is showcased by their customizable features. These include the option to select special materials and O-rings, the choice between a welded or one-piece flanged closure, and the capability to adjust the wall thickness, vents, and other modifications based on specific application needs.

Key Benefits of Clamp Type Quick Closures

Speed and Ease of Access

Among the foremost benefits of Clamp Type Quick Closures is their capacity to provide rapid and uncomplicated access to pipelines. This speed is critical in a variety of industrial applications where pipelines need frequent inspections or maintenance. The unclamping and opening process is straightforward and quick, reducing downtime in operations.

Safety Features

Safety is paramount in any industrial setting, and these closures are designed with that principle in mind. They feature a Pressure Alert Valve, which operates without the need for an additional O-ring, ensuring that the closure can’t be opened if internal pressure exists. This feature provides an extra layer of protection for operators. Additionally, the large cross-section O-ring design not only ensures a positive seal but also offers protection from tools and debris, further enhancing the safety of the system.

Robust and Durable Design

Clamp Type Quick Closures are designed for longevity and durability. Built to meet rigorous standards such as ASME B31.3/B31.4/B31.8/CSA Z662 Cat. I, these closures are crafted from materials that withstand harsh environmental conditions and resist wear and tear. This robust design contributes to longer service life, reduced maintenance costs, and enhanced operational reliability.

Efficiency and Performance in Various Pipeline Applications

These closures are engineered for optimal performance in a wide array of pipeline applications. Their design allows for customization to suit specific requirements, from wall thickness to vent modification. This adaptability makes them suitable for various pipeline sizes and specifications, from smaller diameters of 2” (DN50) to larger ones of 48” (DN1200). Whether used in the oil and gas industry, power generation, or the petrochemical sector, Clamp Type Quick Closures deliver high efficiency and performance, facilitating smooth and safe operations.

Comparison with Other Types of Closures

Clamp Type Quick Closures have their unique set of strengths and weaknesses compared to other types of closures, such as Threaded Closures, Bolted Flange Closures, and Swing Check Closures. Let’s delve into the comparison:

Strengths of Clamp Type Quick Closures:

- Speed and Ease of Use: Clamp Type Quick Closures offer rapid access to the interior of pipelines and pressure vessels, significantly reducing the time required for inspections and maintenance. Unlike Bolted Flange Closures which require the time-consuming process of unbolting and re-bolting during every access, Clamp Type Quick Closures can be opened and closed quickly with minimal tools.

- Safety Features: The safety mechanisms of Clamp Type Quick Closures, such as the Pressure Alert Valve, offer enhanced safety over other closure types. This valve prevents the closure from being opened when internal pressure is present, a feature not universally found in other closure types.

- Versatility: Unlike Threaded Closures which are limited to smaller pipeline sizes, Clamp Type Quick Closures can accommodate a wide range of pipeline diameters, from 2” to 48” (DN50 to DN1200). Additionally, their customizable features allow them to be tailored to specific application needs.

Weaknesses of Clamp Type Quick Closures:

- Cost: In comparison to simpler closure types such as Threaded Closures, Clamp Type Quick Closures can be more expensive due to their complex design and the high-quality materials used in their construction.

- Maintenance: While these closures are designed for durability, their intricate design might require more specialized maintenance than more straightforward closure types. For instance, the O-ring seals may need periodic replacement to maintain optimal sealing performance.

- Installation: Compared to Swing Check Closures, which can be installed with minimal effort, Clamp Type Quick Closures might require more time and expertise to install due to their more complex design.

Overall, the choice between Clamp Type Quick Closures and other types of closures depends on a variety of factors, including the specific application, the size and pressure rating of the pipeline, and operational requirements such as frequency of access, safety considerations, and budget constraints.

Conclusion

Clamp Type Quick Closures represent a significant advancement in the realm of pipeline management and pressure vessel technology. They have proven to be invaluable tools for a variety of industries, thanks to their unique blend of speed, safety, durability, and efficiency.

Their key benefits—speed and ease of access, robust safety features, durable design, and superior performance in a wide array of pipeline applications—have contributed to their growing popularity and application across various industries. From oil and gas to power generation and petrochemical sectors, these closures have transformed the way pipeline inspections and maintenance procedures are executed, significantly reducing operation downtime and enhancing overall operational efficiency.

Despite some potential challenges, such as higher initial costs, more specialized maintenance, and more complex installation procedures compared to simpler closure types, the advantages offered by Clamp Type Quick Closures often outweigh these issues. Their added safety features, speed and ease of use, and adaptability for different application needs make them a worthy investment for many industrial operations.

Looking ahead, as industries continue to seek solutions that enhance safety, efficiency, and ease of use, the role of Clamp Type Quick Closures is expected to grow. As technology advances, we can anticipate further improvements in their design and operation, ensuring they continue to meet the evolving demands of industrial applications.

Reviews

There are no reviews yet.