Description

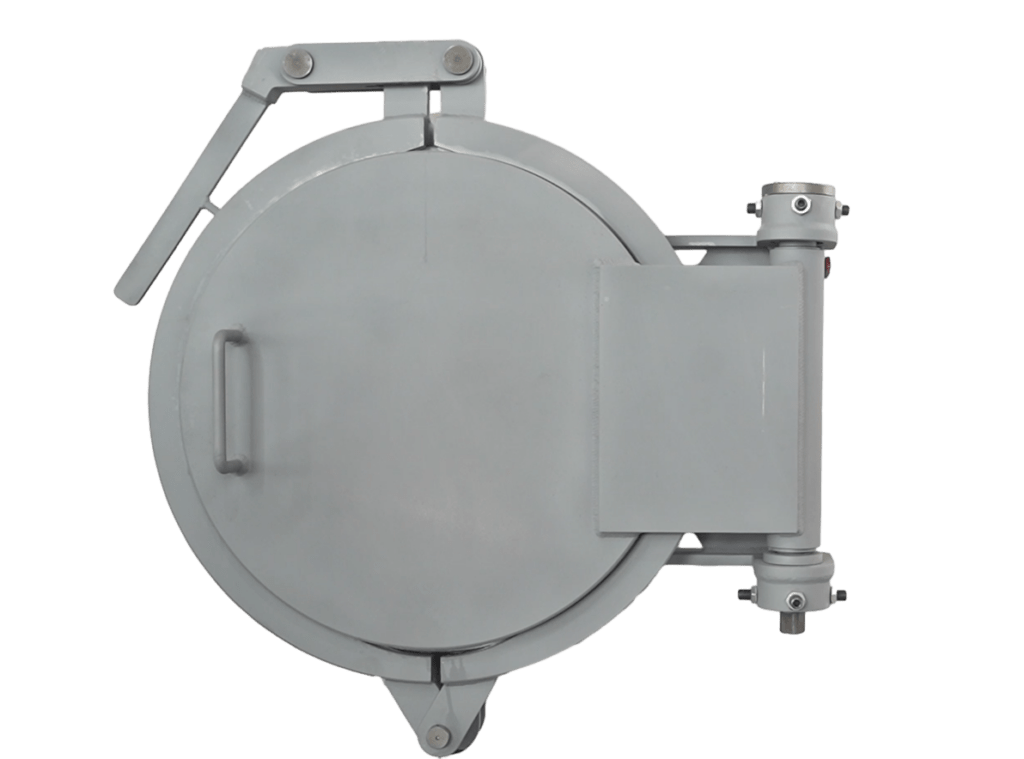

Clamp Quick Opening Closure | ||||

Design Pressure | 1.6MPa-30MPa | |||

Corrosion Allowance | 2mm | |||

Seismic Fortification Intensity | 7 Degrees | |||

Work Medium | Oil, natural gas, Water and ore pulp, etc. | |||

Opening Time | Within 60s less than 200N | |||

Opening Type | Vertical or Horizontal | |||

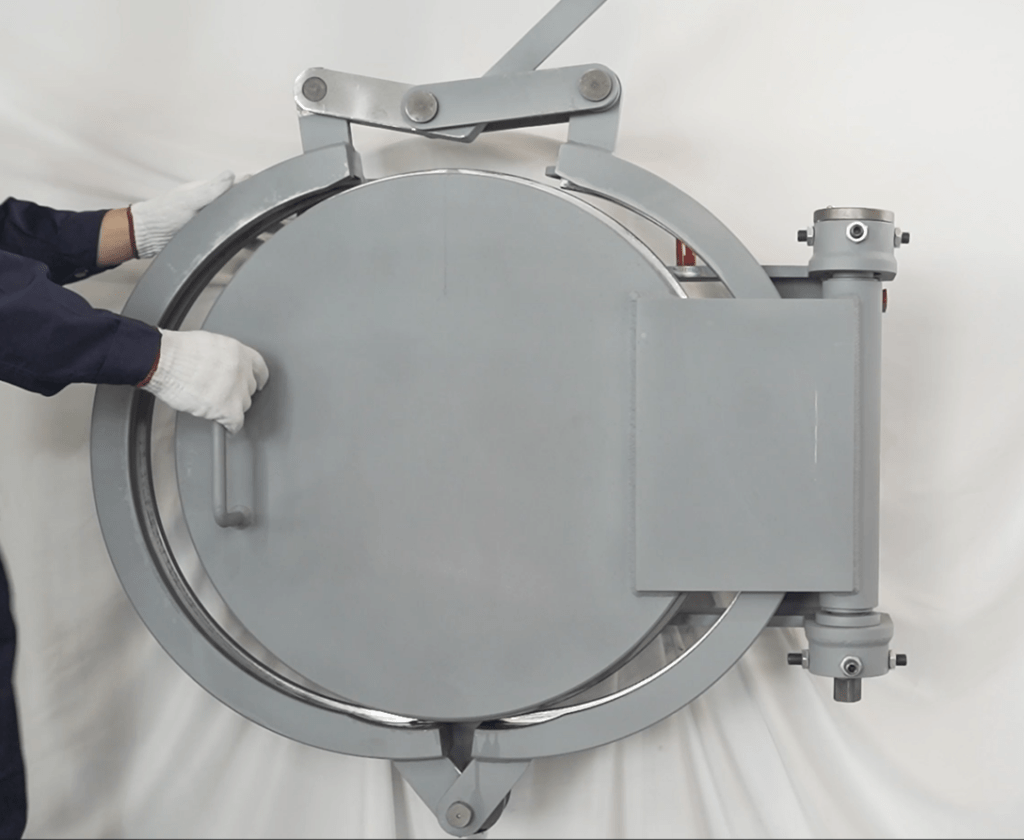

Operating this procedure requires professionals who have undergone specialized training. All employees must first pay close attention to the signs on the Clamp Closure. It is crucial not to use incorrect tools, as this could cause irreversible damage to the safety chain system; for instance, one should never attempt to open the blind with a hammer. The next step is to manually loosen the upper vent bolt. If there is a sound or oil starts to spill, it indicates the cylinder is still under pressure. In such a case, the pressure must be released, but remember that an internal pressure relief port cannot be used with the vent screw. Once the pressure within the cylinder is fully released, the operator can manually unscrew the hollow screw. A small chain connects the hinge with the safety plug, and as the screw continues to be unscrewed, the bolt ends gradually lengthen until the tail bolt and the nut bracket make contact. The operator then grabs the handle of the slider and opens the closure’s flange.

At EMT, we produce Clamp Closures primarily for pipeline applications, catering to a wide range of diameters from 2” to 48” (DN50 to DN1200). Recognizing the diverse needs of pipeline operations, we ensure our closures meet ASME B31.3/B31.4/B31.8/CSA Z662 Cat. II certifications with a 0.5/0.6 design factor. Our popular Clamp Style Closure combines superior quality components, user-friendly design, and a prioritization of safety, delivering an exceptional solution for your pipeline needs.

Safety Operation and Maintenance

Operators must carefully read this operating manual to understand the Quick Opening Closure’s (QOC’s) structure and usage.

Before opening the QOC, ensure to unscrew the checkscrew until the pressure in the barrel drops to zero. Only then can you proceed to the next step.

Ensure that the interlocking board is properly installed when closing the closure cover. Once this is confirmed, the system can be pressurized for use.

During operation, it is strictly forbidden to hit or crash the pressure-sensitive parts and components.

After each use, apply anti-corrosion grease to all connected threads, rotating parts, and sealing surfaces.

If the equipment is not going to be used for an extended period of time, apply anti-corrosion grease to all connected threads, rotating parts, and sealing surfaces at least once a year.

If the QOC is installed in an outdoor location, additional protective facilities should be added.

Regularly inspect the primary pressure-bearing parts of the QOC, such as the closure cover, barrel flange, and clamp ring. If you discover severe corrosion, cracks, or other issues, please engage professional personnel to identify the cause and address the problem.

Real-life Applications

Clamp Quick Closures are extensively used in the oil and gas industry due to their ability to provide fast and secure sealing of pressure vessels and pipelines. For instance, they are often implemented in launching and receiving traps in pipeline pigging operations. These devices require frequent opening and closing for the insertion and extraction of pipeline pigs, and the quick closure mechanism of the Clamp Ring design significantly reduces downtime, enhances efficiency, and improves safety by minimizing exposure to pipeline contents.

In addition to the oil and gas sector, Clamp Quick Closures find utility in a variety of other industries with high-pressure environments. Within the chemical industry, they are used on reactors and vessels that require regular access for cleaning, maintenance, or batch changeovers. In the power generation sector, they are employed on boiler drums and heat exchangers to facilitate easy access for inspection and maintenance. The food and beverage industry also utilizes them on pressure vessels for sanitation purposes. The simplicity, reliability, and speed of operation offered by Clamp Quick Closures make them a favored choice across a wide range of industrial applications requiring frequent and safe access to high-pressure systems.

Other Types of Quick Closures

Besides the Clamp Closure, we also produce two other types of Quick Opening Closures: Lock Ring Quick Opening Closure and Bayonet Quick Opening Closure. Each of them has two types: the vertical type and the horizontal type. According to the position of pipelines, different quick opening closures can be chosen. The Lock Ring Quick Opening Closure offers a safe and efficient solution for frequent access needs, providing a secure seal and easy opening mechanism. The Bayonet Quick Opening Closure, on the other hand, boasts a simple, robust design that’s ideal for high-pressure applications, ensuring reliability and durability even under demanding conditions. Both options offer unique advantages, enhancing your operational efficiency and safety. If you require any assistance, please feel free to reach out to us. We’re committed to delivering top-notch service tailored to your specific needs.

Summary

In conclusion, the Clamp Quick Closures are indispensable tools in various industries, notably the oil and gas sector. They provide a fast, secure, and efficient method for sealing pressure vessels and pipelines, while also offering easy access for maintenance, inspection, cleaning, and other operational necessities.

Their design and operational parameters, as well as their safety procedures, reflect a keen attention to detail and a strong emphasis on durability, safety, and efficiency. This is evident in the rigorous safety operation and maintenance guidelines, which emphasize a proactive approach to maintaining the device’s functionality and safety.

Moreover, their real-life applications in diverse industrial sectors further underscore their versatility and utility. Whether it’s in launching and receiving traps in pipeline pigging operations or enabling regular access to reactors and vessels in the chemical industry, these closures have proven to be reliable and vital components in high-pressure environments.

The emphasis on professional training for operators, the meticulous guidelines for safe operation, and the necessity for regular maintenance all highlight a commitment to safety and operational efficiency. As we continue to innovate and advance in industrial processes, the role of such efficient, safe, and versatile tools as these quick opening closures will undoubtedly remain significant.

Reviews

There are no reviews yet.