Description

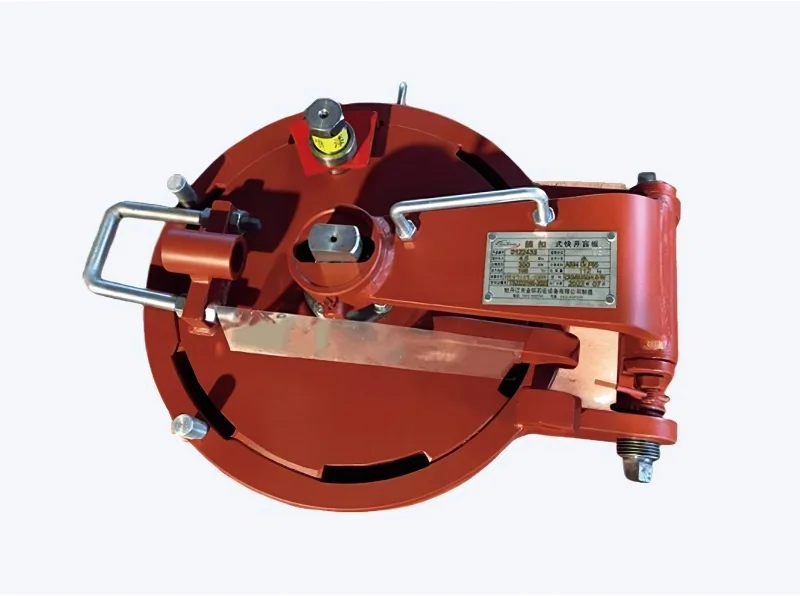

Description of Bandlock

EMT is a globally recognized leader in the production of quick-opening closures. Our EMT Bandlock sets the standard in high-pressure application closures, with over 20,000 units in operation worldwide.

EMT Bandlock Closures provide rapid, horizontal, or vertical access to any pressure vessel. Unlike other quick-opening closures, they can be operated safely at an exceptional speed—any size of unit can be opened or closed in less than a minute, with no special tools needed.

Computer-aided technology has greatly contributed to the design of Bandlock. The main pressure-loaded sections have been designed to save weight, utilizing finite element analytical techniques and proof testing by strain gauges, all while adhering to primary pressure vessel code requirements.

The dependable locking band system, from which the product derives its name, features a conical thrust ring made of duplex stainless steel. Positioned between the door and hub, it evenly distributes the pressure load across the entire 360° perimeter of the hub.

Features of Bandlock

BUILT-IN SAFETY FEATURES

The EMT Bandlock is characterized by its safety features, incorporated throughout its design and production process. It includes a manually operated pressure warning screw within the mechanism, ensuring the door cannot be unlocked until the pressure inside the vessel is confirmed to have been released. Additional safety enhancements, like mechanical key interlocks, can be added and connected with control valve operations. For total safety assurance, the locking band is always visible, complying with design code mandates and enabling the operator to visually verify that the door is securely locked and closed.

DOOR PIVOTING

The door is designed to pivot twice on hinges equipped with self-lubricating bearings for horizontal application. The bolted placement allows for wear adjustment and can be configured for either right or left swing. For vertical installation, a davit is included which allows the EMT Bandlock door to be lifted and moved away from the hub. When diameters exceed 30″, lifting eyebolts are typically used in place of the davit, permitting the door to be lifted aside.

SEAL COMPOSITION

The default seal is made of Nitrile material with a shore hardness of 80°. Alternatives like Viton, HNBR, and materials resistant to explosive decompression are available as well. The temperature compatibility ranges from -45°C to +210°C depending on the specified elastomer.

HYDROSTATIC EXAMINATION

While typically part of the final vessel inspection, an individual closure hydrostatic test can be optionally conducted.

DISTINCTIVE SEAL WITH EMBEDDED ANTI-EXTRUSION SPRING

The specially designed servo-acting lip seal creates a completely airtight seal, activating at zero pressure. In both Horizontal and Vertical Installations, the seal is placed in the door, away from the operational area for protection and longevity, and can be easily installed without tools. The one-piece mold is offered in various elastomers and includes a stainless steel spring to combat extrusion and support full vacuum capability.

CONSTRUCTION MATERIALS

Hubs made from forged steel, with doors of forged or plate steel, can be supplied to meet all global material specifications. Materials complying with NACE Standard MR-01-75 / ISO 15156 are also available.

Key Features of Bandlock

- Rapid Access: Bandlock allows for swift access to pressure vessels, improving maintenance efficiency and reducing downtime.

- Horizontal or Vertical Operation: It is versatile and can be operated both horizontally and vertically, making it suitable for various applications.

- Scalability: GD Engineering’s Bandlock design can be upscaled to accommodate very large diameter closures for different industrial needs.

- Enhanced Safety: Quick-opening closures like Bandlock are designed with safety in mind, ensuring that access to pressure vessels is secure and controlled.

Applications of Bandlock

Quick-opening blind plates are widely used in various fields such as natural gas, chemical, metallurgy, and others in equipment such as filters, tanks, filter separators, metering skids, cyclone separators, heat exchangers, and more. These are horizontal and vertical pressure vessel devices that operate under high pressure, have a large volume, and require periodic opening and closing. The applicable mediums are oil, gas, water, and non-corrosive chemical raw materials (strongly corrosive mediums should use other materials such as stainless steel for processing). The applicable temperature range is -40℃ to 100℃.

Technical Specifications

| Design Pressure | 1.6MPa-30MPa |

| Corrosion Allowance | 2mm |

| Work Medium | Oil, Natural gas, Water and ore pulp, etc. |

| Seismic Fortification Intensity | 7 Degrees |

| Opening Time | Within 60s less than 200N |

| Size Range | 6″ to 100″ Nominal diameter |

| Class Ratings | ASME 150# through to 2500# |

| For Pressures in excess of 2500# please contact EMT | |

| Closure Orientation | Horizontal or Vertical |

| Termination Design Specifications | ASME B31.3, B31.4, B31.8 |

| Other International standards are available on request | |

| Types of Connection | Butt Welded, Butt Welded with miter for inclined/declined vessels, reduced access or flanged to clients’ requirements |

| Elastomeric Sealing | Nitrile, Viton, and Rapid Gas Decompression Resistant. Other material options available on request |

| Standard Closure Finish | Removable rust preventative for the client to finish paint after welding to the vessel |

Frequently Asked Questions

- What is the main advantage of the Bandlock system over traditional closure systems?

- Bandlock provides rapid, safe access to pressure vessels, reducing downtime and improving efficiency. It can be operated both horizontally and vertically, and no special tools are needed for opening or closing.

- What safety features does Bandlock incorporate?

- Bandlock has several built-in safety features including a manually operated pressure warning screw, a visible locking band, and the option to add mechanical key interlocks.

- How does the Bandlock door work?

- The door is designed to pivot on hinges equipped with self-lubricating bearings. For horizontal installations, the door can swing left or right, and for vertical installations, the door can be lifted and moved away from the hub.

- What materials are used in the construction of Bandlock?

- Bandlock hubs are made from forged steel, with doors of either forged or plate steel. Materials complying with NACE Standard MR-01-75 / ISO 15156 are also available.

- Can the Bandlock system be customized to my specific needs?

- Yes, Bandlock can be tailored to meet specific size, pressure, and material requirements, making it highly adaptable to varying industrial needs.

- What is the operating temperature range of Bandlock?

- The default seal is made of Nitrile material with a temperature compatibility range from -45°C to +210°C, depending on the specified elastomer.

- What industries typically use the Bandlock system?

- Bandlock is used in a variety of industries, including natural gas, chemicals, metallurgy, and more. It’s commonly found in equipment such as filters, tanks, separators, metering skids, and heat exchangers.

- How quickly can the Bandlock be opened or closed?

- Any size of Bandlock unit can be opened or closed in less than a minute, significantly reducing downtime.

Summary

EMT’s Bandlock is a globally recognized quick-opening closure system used in high-pressure applications, with over 20,000 units in operation worldwide. Its unique design allows for rapid, horizontal, or vertical access to any pressure vessel, and it can be safely operated at high speed. The Bandlock system includes built-in safety features, such as a manually operated pressure warning screw and visible locking band. The door pivots on self-lubricating bearings and can be adjusted for wear and swing direction. The standard seal is made of 80° shore hardness Nitrile, with alternatives available. Applications of Bandlock range from pipeline pig traps to filters, coalescers, strainers, separators, meter skid systems, and hydrocyclones. The system offers various technical specifications, including a design pressure of 1.6MPa-30MPa, a corrosion allowance of 2mm, and an opening time of less than 60 seconds for units less than 200N. It has a size range of 6″ to 100″ nominal diameter and is available in both horizontal and vertical orientations.

Reviews

There are no reviews yet.