Description

Are pipeline pigs essential? Yes, indeed. Pipeline pigs are critical tools used for pipe cleaning across several industries, notably the oil and gas sector. Pipelines that transport oil, water, gas, chemicals, and more require regular cleaning, and pipeline pigs are often the most effective solution. Different types of pipeline pigs serve various functions: some absorb water, others remove rust, and some scrape off pipeline impurities. In response to these varied requirements, we have designed a range of cleaning pigs. These include bare foam pigs, polly foam pigs, foam pigs equipped with brushes, pigs constructed from ABS, and pigs entirely made of polyurethane, among others.

What are Pipeline Pigs ?

Pipeline pigs are specialized tools that are vital to the maintenance and operation of pipelines, which are critical for the transportation of various substances such as water, oil, and gas. These devices are designed to traverse the pipeline system, performing crucial tasks like removing blockages caused by debris or buildup and conducting inspections for any potential damage or wear inside the pipe. The use of pipeline pigs is crucial to ensuring the continuous flow and efficient operation of the pipeline system. By providing an effective method of cleaning and inspecting, they help to prevent disruptions, minimize the risk of costly damage or leaks, and play a key role in maintaining the safety and reliability of pipeline networks.

Understanding Pipeline Pigs

Pipeline pigs are devices that are used to clean, inspect, and perform maintenance tasks inside pipelines. They were initially called “pigs” because the early models, made from materials like straw, leather, and wire, made a squealing sound as they moved through the pipes. Over time, the term “pig” has also come to stand for “Pipeline Inspection Gauge” or “Pipeline Intervention Gauge”.

When pipeline technology first began, manual cleaning was the norm. As pipelines grew longer and more complex, the need for a more efficient cleaning method arose. This led to the development of the first pipeline pigs. Today, pigs are made from a variety of materials and come in many shapes and sizes to suit different types of pipelines and tasks.

The process of using pipeline pigs involves two key components: a pig launcher and a pig receiver. The pig launcher is a device connected to the pipeline that introduces the pig into the pipeline. The pig is then propelled through the pipeline by the force of the fluid (like oil or gas) behind it.

As the pig moves through the pipeline, it performs its task. For cleaning pigs, this might involve scraping off buildup or debris from the pipeline walls. For inspection pigs, they might be collecting data about the pipeline’s condition.

Eventually, the pig reaches the pig receiver, another device connected to the pipeline at the other end. The receiver safely captures and removes the pig from the pipeline. After the pig is removed, it can be cleaned, inspected, and prepared for its next use. If it’s an inspection pig, the data it collects can be downloaded and analyzed to assess the pipeline’s condition.

The Role of Pipeline Pigs

Pipeline pigs play a crucial role in maintaining the health and efficiency of pipelines across various industries. They are used primarily for three reasons: cleaning and maintenance, inspection, and separation of different products within the pipeline. By performing these roles, the products help to ensure the safe and efficient operation of pipelines. They help to prevent blockages, identify potential issues before they become serious problems, and allow for the efficient use of pipeline infrastructure.

Cleaning and Maintenance: Over time, substances like oil, gas, or chemicals can leave residue or buildup along the inside walls of a pipeline. If left unchecked, this can reduce the efficiency of the pipeline and even lead to blockages. Cleaning pigs are designed to remove this unwanted build-up, ensuring that the pipeline remains clean and functions at its best.

Inspection: Pipelines can suffer from wear and tear, corrosion, or other types of damage. Inspection pigs, also known as “smart pigs,” are equipped with sensors and recording equipment that can detect these issues. As the pig travels through the pipeline, it collects data about the pipeline’s condition. This information can be analyzed later to identify potential problems and plan for repairs or maintenance.

Separation: When different products need to be transported through the same pipeline, pipeline pigs can be used to keep them separate. This is important in industries like oil and gas, where different types of products (like crude oil and refined products) may need to share the same pipeline.

Types of Pipeline Pigs

EMT Pipeline Products offers a wide range of pipeline pigs designed to meet various pipeline needs, from cleaning and maintenance to inspection and separation.

Bare Foam Pigs: These are simple, lightweight pigs made from foam. They are often used for light cleaning tasks, like removing water or oil residue from the pipeline.

Polly Foam Pigs: Similar to bare foam pigs, polly foam pigs are also used for light cleaning. They are coated with polyurethane, which makes them more durable and allows them to handle slightly tougher cleaning jobs.

Foam Pigs with Brushes: These pigs have brushes attached to their bodies. The brushes help in scraping off harder buildups or deposits from the pipeline walls.

ABS Cleaning Pigs: Made from Acrylonitrile Butadiene Styrene (ABS), these pigs are durable and resilient, making them suitable for more demanding cleaning tasks.

Skeleton Pigs: These pigs have a flexible, skeleton-like structure that allows them to navigate bends and turns in the pipeline while performing their cleaning or inspection tasks.

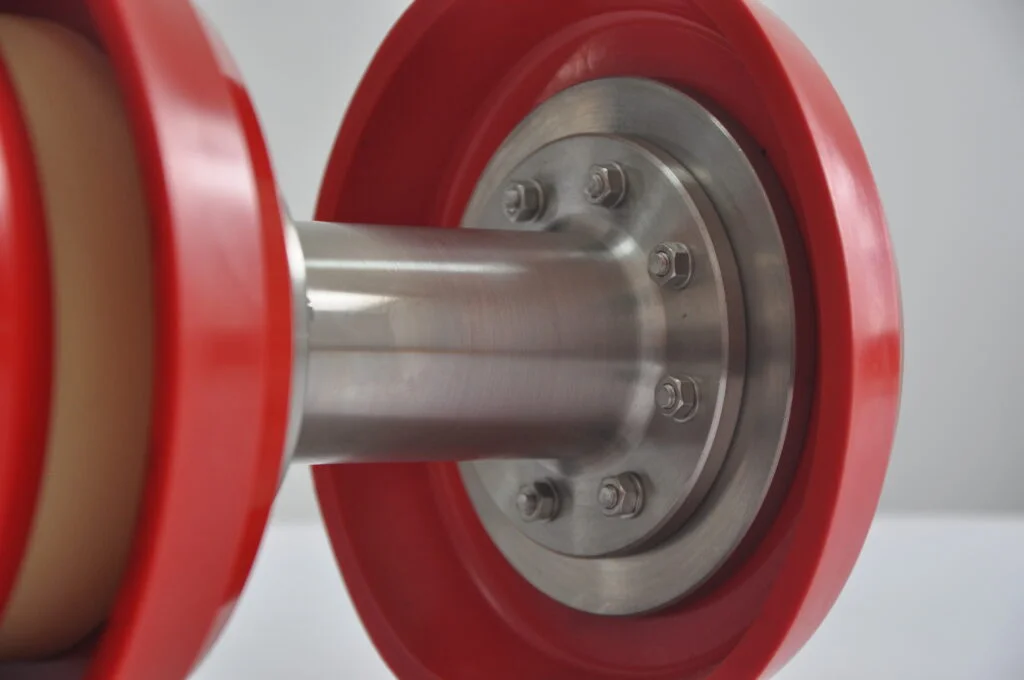

Pigs with Discs or Cups: These pigs are equipped with rubber discs or cups, which help in sealing the pipe and improve the efficiency of the pig in cleaning or separating different products in the pipes.

Solid Cast Pigs: These are robust, heavy-duty pigs used for the most challenging cleaning tasks. They are made from solid materials like cast iron or steel.

Ball Pigs: These are spherical pigs often used for sealing, cleaning, or displacing fluids in the pipeline. They are also used to test the roundness and capacity of new pipelines.

Conclusion

Pipeline pigs are indispensable tools for ensuring the efficient operation and maintenance of pipelines across various industries, particularly in the oil and gas sector. They play a vital role in cleaning and maintaining pipelines, inspecting for potential damage, and facilitating the separation of different products within the same pipeline. They are instrumental in preventing blockages, identifying potential issues early, and maximizing the use of pipeline infrastructure.

EMT Pipeline Products offers a broad assortment of pipeline pigs to meet diverse needs. From simple bare foam pigs to robust solid cast pigs, each type is designed for specific tasks, whether it’s light cleaning, navigating intricate pipeline bends, or handling demanding cleaning tasks. By selecting the right pig for the job, operators can ensure the longevity and efficiency of their pipeline systems and maintain the continuous and safe transport of essential products.

Reviews

There are no reviews yet.