Katrangan

Mangertos katup DBB

Katup katup blok lan getar (DBB) minangka jinis valve tartamtu sing digunakake utamane ing industri minyak lan gas, nanging uga ing macem-macem aplikasi industri liyane. Tujuan utama katup DBB yaiku mungkasi aliran cairan lan kanggo njamin pamisahan lengkap cairan ing sistem.

Jinis Katup DBB

Flves DBB katon ing rong desain utama: jinis modular utawa pamisah lan jinis integral. Ngerti saben fitur lan aplikasi unik desain bakal mbantu sampeyan milih katup DBB sing paling apik kanggo kabutuhan sampeyan.

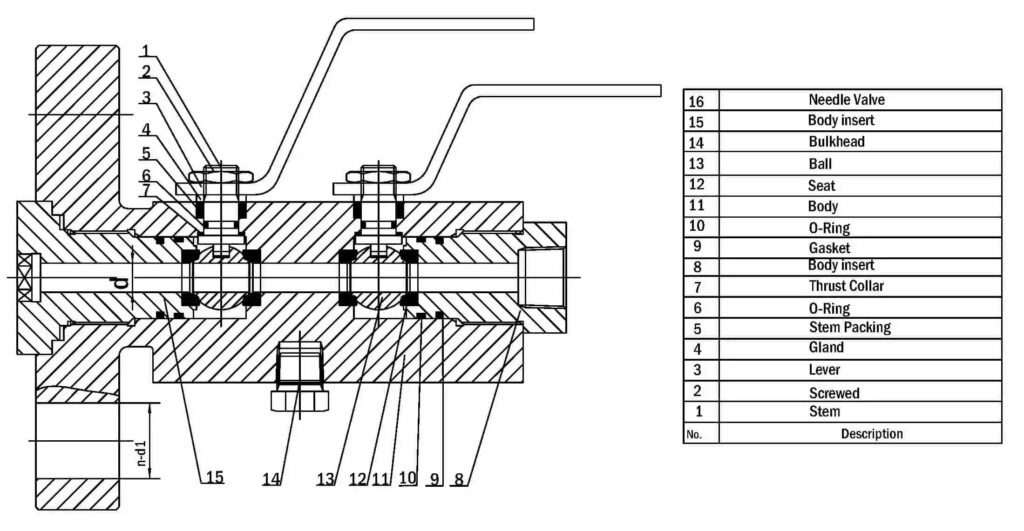

- Modular utawa Split Body Type DBB Valve: Desain iki ditondoi dening struktur bal-bal, nyedhiyakake produk safety tambahan. Ngarsane rong bal ing awak klep siji njamin blockage dobel, fitur kritis ing aplikasi sing berisiko tinggi. Komponen utama desain iki yaiku katup jarum saluran, kanthi strategis dumunung ing antarane loro bal. Katup iki nggampangake lemari katup, mbisakake tekanan sing bakal disetel maneh nalika dibutuhake. Modulitas desain iki, sing digampangake dening konstruksi awak telung potongan, nggawe serbaguna lan mupangate kanggo akeh aplikasi, kalebu instrumen lan pipa. Katup kasebut teka ing macem-macem ukuran, wiwit saka 1 nganti 24 inci, lan bisa ngatasi rating kelas tekanan tekanan, saka API 3,000 kanggo API 10,000, lan ing kabeh skor kelas tekanan saka 150 nganti 2,500 lbs.

- Katup DBB: Katup kasebut, utamane ing industri instrumen, mlebu ing plethora ngrancang kanggo nyukupi kabutuhan. Desain kalebu flange-flange-flange, flange-benang, injling, injling, lan bal lan jarum, nawakake keluwesan kanggo macem-macem aplikasi industri. Padha karo jinis modular utawa pamisah, integral DBB uga duwe katup jarum saluran sing dipanggonke ing antarane rong bal. Iki ngidini kanggo draining katup lan ngreset tekanan kanggo nol yen dibutuhake. Desain integral dikenal kanthi konstruksi lan kemampuan kanggo meksa kanthi efisien nangani.

Cara milih katup DBB sing pas

Pilih katup blok blok lan getar (DBB) sing cocog kanggo kabutuhan sampeyan mbutuhake pangerten babagan aplikasi kasebut, jinis medium sing dikontrol, lan kahanan operasional, suhu utamane. Ayo luwih jero menyang saben faktor kasebut:

- Alam aplikasi: Syarat tartamtu aplikasi sampeyan duwe peran penting kanggo nemtokake katup DBB sing cocog. Contone, yen sampeyan kudu njaga integritas sistem nalika ndandani pipa, katup DBB bisa nyedhiyakake pamisahan sing dibutuhake. Ing skenario kaya ngono, sampeyan bisa nggunakake katup gapura kanggo ngalangi aliran કstream. Kangge, valve ball bisa digunakake kanggo ngeculake cairan saka bagean pipeline sing diblokir, ngidini ndandani kanggo urip kanthi aman. Ngerti inctrikasi aplikasi sampeyan bisa nuntun sampeyan menyang jinis lan konfigurasi DBB lan konfigurasi sing paling cocog.

- Jinis Sedheng: Jinis medium, utawa media, sing sampeyan pengin ngontrol uga pengaruh banget kanggo milih katup DBB. Kanggo ngontrol cairan sing diontrol lan gas sing padhet, umpamane, sampeyan bisa uga butuh bal-balan sing lol, jagad, utawa gapura katup minangka katupan blokir kanggo ngatasi jinis media kasebut. Katup jarum, sing dikenal kanthi tliti, asring dipilih minangka katup getihen ing kahanan kaya ngono. Yen ngatasi media corrosive, bisa uga milih kanggo katup DBB baja tahan karat, sing menehi resistensi apik banget kanggo karat, mesthekake media kasebut diblokir kanthi efektif tanpa ngrusak katup kasebut.

- Suhu operasi lan kahanan tekanan: Kahanan sing ditindakake dening operasi sampeyan uga bakal mengaruhi pilihan katup DBB. Tekanan tinggi, aplikasi suhu dhuwur bisa uga nggunakake valves bal anti statis minangka katup blok. Katup jinis iki digunakake kanggo ngangkono kanggo nahan tekanan fluktuasi lan geter, supaya bisa digunakake ing operasi sensitif. Ing operasi kontras, kurang apik bisa uga cocog karo katup gapura DBB kanthi wedge dobb kanthi wedge luwes lan katup getih sing dibutuhake, sing bisa menehi resistensi tekanan tinggi.

Kanthi mikirake faktor kasebut - sifat aplikasi kasebut, jinis medium, lan kahanan operasional - sampeyan bisa nggawe keputusan sing ngerti nalika milih kabutuhan DBB, mesthekake yen bakal nyukupi kabutuhan khusus lan efisien kanggo sistem sampeyan.

Keuntungan nggunakake katup DBB

Klambi blok lan getihen (DBB) kanthi apik dirancang kanggo ngganti metode tradisional gabung karo katup individu bareng kanggo nggayuh dual isolasi. Desain streamline iki nawakake sawetara keuntungan sing signifikan:

- Spasi, bobot, lan efisiensi instalasi: Katup DBB nggabungake macem-macem fungsi katup dadi unit siji, nyebabake tabungan sing gedhe banget ing babagan bobot lan ruang nganti 60% ing sawetara kasus. Desain kompak iki pancen mupangate kanggo instrumen instrumen utawa kandhang instrumen. Salajengipun, kanthi gampang nggawe jumlah komponen sing bakal diinstal, valv DBB uga bisa nyuda wektu instalasi nganti 70%.

- Keamanan lingkungan: Salah sawijining kaluwihan katup DBB minangka potensial kanggo nyilikake efek lingkungan. Kanthi signifikan nyuda jumlah bocor pathokan potensial, katup dbb nyuda kemungkinan bocor mbebayani, nambah keamanan operasi sakabehe.

- Pangopènan Keselamuhan: Nalika tugas pangopènan kudu ditindakake mudhun saka katup isolasi pisanan, dual isolasi penting. Floves DBB netepi syarat iki kanthi sampurna. Dheweke nampilake bal utawa katup vent jagad sing ngidini supaya bisa dadi penebet tekanan sing direncanakake ing antarane katup isine.

- Versatility lan tambahan fungsi: Dalves DBB wis berkembang kanggo kalebu fungsi tambahan kayata injeksi kimia lan sampling, luwih akeh keperluan. Sawetara desain malah nggabungake katup kontrol, nggawe katup multi-fungsi sing luwih serbaguna kanggo macem-macem aplikasi.

Intine, valves DBB minangka game ing industri katup, nyedhiyakake tabungan sing gedhe, ruang, lan wektu instalasi, ningkatake safetyan lingkungan, menehi kabegjan kanggo pangopènan, lan mbahas versatilasi kanthi fungsi.

Industri lan aplikasi kanggo katup DBB

Klambi blok lan getihen (DBB), sing dikenal kanggo fitur versatility lan safety, golek aplikasi ing industri sing akeh. Ing industri minyak lan gas, umpamane, katup DBB penting kanggo pamisahan sajrone pangopènan utawa kanggo ngeculake gas lan cairan sing aman. Kajaba iku, ing industri petrokimia, digunakake kanggo kemampuan ngisolasi sing efektif, utamane nalika nangani cairan mbebayani. Industri kimia uga entuk manfaat saka panggunaan katup DBB, ing ngendi njamin konten sing aman lan pembentuan kimia sing agresif. Tanduran generasi tenaga, katup dbb asring digunakake kanggo ngatur sistem tekanan kanthi aman. Dheweke uga nemokake aplikasi ing tanduran perawatan banyu, ing ngendi mbantu ngatur aliran aliran lan bagean ngisolasi kanggo pangopènan. Ringkesan, katup DBB digunakake ing ngendi wae perlu solusi kompak sing nawakake pamisahan kaping pindho lan fungsi getih sing bisa digunakake kanggo nggawe operasi sing aman.

Katup dbb vs. Katup Dib

- Blok blok lan katup getihen (DBB): Kadeg DBB sing penting yaiku rong permukaan sealing utawa mekanisme (blok) sing bisa ngisolasi aliran medium (kaya gas utawa cairan). Fungsi 'gethah' minangka fitur tambahan sing ngidini tekanan sing kepepet ing antarane rong blok kasebut supaya aman utawa 'bled' metu, yen prelu. Iki biasane digayuh liwat vent utawa saluran saluran katup ing rongga awak katup. Katup DBB digunakake ing aplikasi kritis ing bocor bisa duwe akibat sing serius, lan perlu kanggo njamin pamisahan lengkap medium.

- Pengasingan kaping pindho lan katup getih (Dib): Valve Dib uga duwe loro permukaan sealing, padha karo katup DBB, nanging kanthi prabédan sing penting. Ing katup Dib, loro-lorone permukaan utawa mekanisme utawa mekanisme kasebut iki dirancang kanggo bidirectional, i.e., bisa ngalangi aliran medium saka salah siji arah (hulu utawa hiltrsream). Fungsi 'getihen' padha karo katup DBB - ngidini tekanan sing kepepet ing antarane rong blok supaya bisa diuripake kanthi aman. Fitur bidirectional iki nggawe Valves Dib sing cocog kanggo aplikasi ing endi arah aliran bisa uga ngganti utawa ing ngendi pamisahan dibutuhake ing loro-lorone katup.

Ringkesan

Klep blok lan getihen (DBB), kasedhiya ing desain modular, kritis ing macem-macem industri, kalebu minyak lan gas, petrokimia, lan generasi kekuwatan. Klambi kasebut nyedhiyakake pamisahan dual lan fungsi getihen, njamin aliran cairan cairan sing lengkap lan safety sing ditingkatake sajrone tugas pangopènan sajrone tugas pangopènan sajrone tugas pangopènan sajrone tugas pangopènan sajrone tugas pangopènan sajrone tugas pangopènan sajrone tugas pangopènan. Pilihan Dalve sing cocog gumantung saka aplikasi aplikasi kasebut, jinis medium sing dikontrol, lan kahanan operasional. Valves DBB nawakake keuntungan sing signifikan kayata ruang lan tabungan bobot, safetyan lingkungan, safety pangopènan, lan fungsi sing ditambahake. Dheweke beda karo pamisahan kaping pindho lan getihen (Dib) ing katup Dib sing nyedhiyakake pamisahan bidirectional.

Ulasan

Durung ana review.