Katrangan

I.Pambuka

Corrosion coupons are vital instruments employed to identify and evaluate the extent of corrosion within pipeline systems. They provide an accurate assessment of the internal corrosion status, which is crucial for the pipeline’s maintenance and preservation. Currently, the corrosion coupons in use both domestically and internationally are generally successful in detecting pipeline corrosion. However, the majority of these devices necessitate pipeline depressurization and cessation of operations, which can lead to substantial economic losses. In response to this challenge, our company has developed a specialized tool that allows for the extraction of the corrosion coupon even while the pipeline is under pressure. This removes the need for pipeline depressurization and shutdown. The primary components of this tool are fabricated from stainless steel, conferring resistance to both acidic and alkaline conditions, as well as superior corrosion resistance. The retrieval tool operates through a mechanical contact mechanism, ensuring both sensitivity and reliability.

II. Technical Characteristics

| Rentang tekanan sing ditrapake | P≤45Mpa |

| Rentang suhu sing ditrapake | -20~100℃ |

| Applicable pipe diameter | D≥DN100 |

| Applicable medium | petroleum products, gas, and other non-corrosive fluids |

| The installation height of the equipment under normal use conditions depends on the pipe diameter (generally not more than 1.5 meters) | |

III. Applications

- Industri minyak lan gas: This retrieval tool is extensively used in the oil and gas industry for routine inspection and maintenance of pipelines. It helps in monitoring the rate of corrosion in pipelines that transport crude oil, natural gas, and other petroleum products.

- Chemical Processing Industry: Ing tanduran kimia, akeh bahan sing diangkut liwat pipelines bisa uga korosif. Alat pengeturan bisa mbantu nemtokake sifat koro-bahan bahan kimia lan efek sing ana ing materi pipa.

- Tanduran Perawatan Banyu: Piranti retrieval coupon Korossion bisa digunakake ing fasilitas perawatan banyu ing endi jumlah banyu sing akeh diangkut liwat pipeline. Piranti kasebut bisa mbantu ngawasi lan ngatur karat sing disebabake dening impurities ing banyu.

- Industri Generasi Daya: Ing tanduran tenaga, utamane sing nggunakake uap, alat kasebut bisa migunani kanggo ngawasi karat ing tabung boiler lan pipeline transportasi uap.

- Aplikasi Marine: Ing platform pengembangan pengembangan lan luar negeri, alat pengembangan bisa digunakake kanggo nyoba karat ing macem-macem komponen sing kapapar ing lingkungan laut sing angel.

- Industri Farmasi: Ing manufaktur farmaseutikal, ing ngendi njaga kesucian produk penting, alat kasebut bisa digunakake kanggo ngawasi karat ing pipelines sing ngangkut macem-macem cairan, gas, lan penundaan.

IV. Pandhuan kanggo Gunakake

- Persiapan sadurunge nggunakake alat kasebut

Mesthekake kanggo nggawe katup piring kanthi mbukak utawa ditutup, banjur mbalikke rotasi rotasi rotasi rotasi hex, saengga hex ndhuwur ngadhepi (jejere sumbu peralatan), sing ora bisa disebabake! - Pandhuan langkah-langkah ing operasi Alat Retrieval

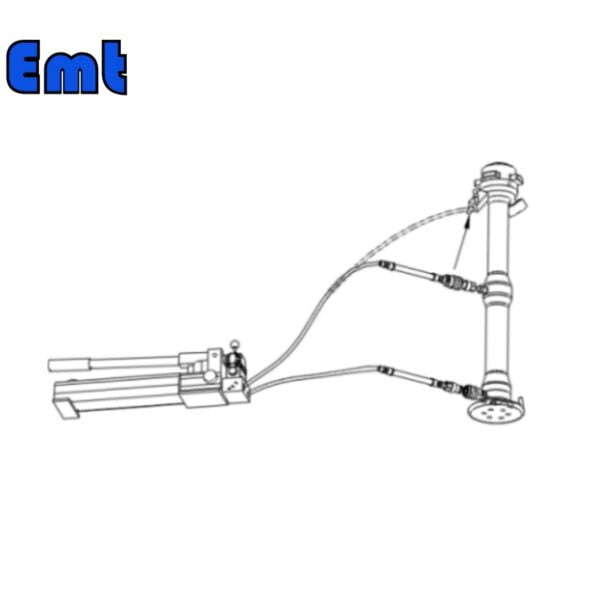

Mbukak Kupon Korosi Instalasi Kupon Korosion (1) Install Adapter (1) Install Retriever (2) Install Hammer Nut and Service Valve (2) Close the Bleed Valve (3) Install of Retriever (3) Open Bypass Valve (4) Remove the corrosion coupon (4) Open the Service Valve (5) Close the Service Valve (5) Install corrosion coupons (6) Close the Bypass Valve (6) Open the Bleed Valve (7) Open the Bleed Valve (7) Open the Seal Screw (8) Open the Sealing Screw (8) Close the Bleed Valve (9) Remove the Retriever (9) Remove the Retriever (10) Remove of Hammer Nut and Service Valve (11) Remove of Adapter (12) Install Pipe Plug and protective cover

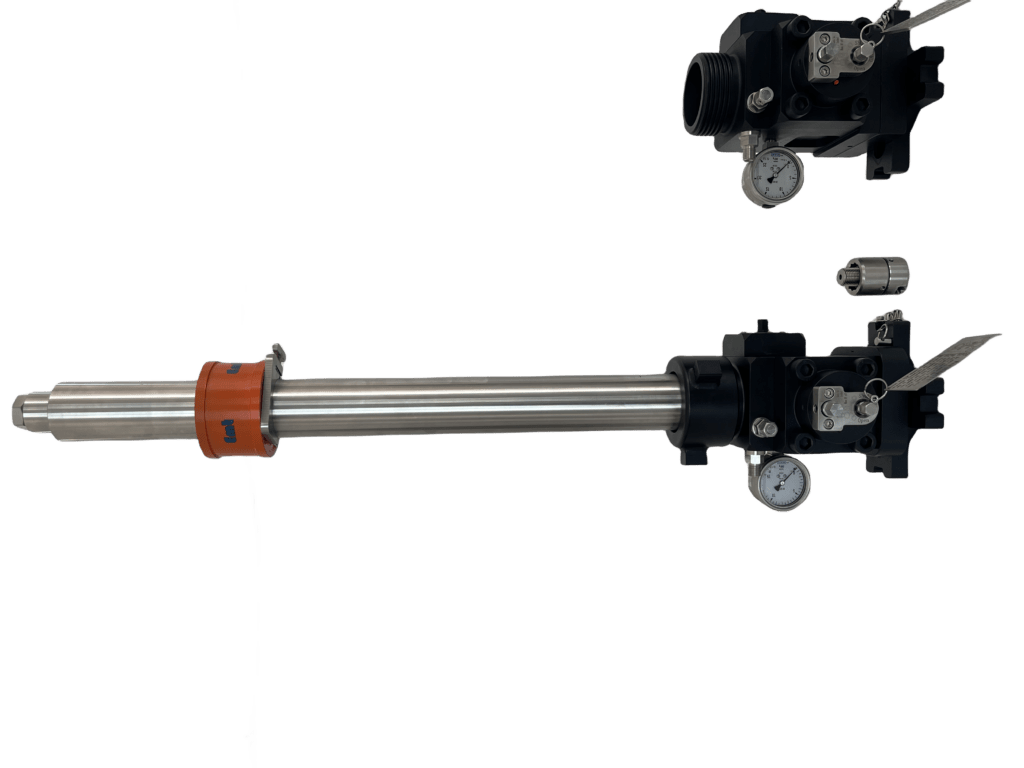

V. Equipment Structure

(1) Hammer Nut— Connecting base and the Service Valve (PTFE coating) ;

(2)Service Valve— Connecting Retriever, used for internal pressure adjustment of pressure removal tools (PTFE coating);

(3) Bleed Valve— Used to release internal pressure of pressure removal tool (stainless steel) ;

(4) Bypass Valve— Used for internal pressure balance of pressure removal tool (stainless steel);

(5) Adapter— Used to connect corrosion coupons and Retriever (stainless steel) ;

(6) Plug Drive— For removing and installing the drive plug of corrosion coupons (stainless steel) ;

(7) Plug Lifter— Used for linkage of internal and external magnetic steel plugs (high-intensity magnetic steel) ;

(8) Stop Block— For fixing Plug Lifter (stainless steel) ;

(9) Retriever— Connecting the gear plate valve for lifting and installation of corrosion coupons (stainless steel);

VI. Maintenance

The maintenance of the pressure retrieval tool, crucial for its longevity and functionality, involves several key steps to be undertaken after each use. Firstly, it is critical to ensure that the tool and each of its components are meticulously cleaned. This step involves wiping off any residual material or debris that may have accumulated during use.

The next step in the maintenance process is to thoroughly dry the tool. It’s important to prevent any moisture from remaining on the retrieval tool as this could potentially lead to rust or other forms of corrosion over time, especially if the tool is stored in a humid environment.

Finally, attention must be paid to all areas of the tool that house O-rings. These areas should be adequately greased after every use. The application of grease is a preventative measure that helps to ward off corrosion damage over time. It also maintains the flexibility and sealing ability of the O-rings, ensuring they perform effectively during each use.

In summary, regular and meticulous cleaning, drying, and greasing of the pressure removal tool and its components are vital steps in preserving its functionality and extending its lifespan.

VII. Summary

This essay introduces the Corrosion Coupon Retrieval Tool, an innovative solution to pipeline corrosion. Traditional methods of corrosion coupon extraction necessitate pipeline shutdown, but this inventive tool allows for extraction under pressure, thus circumventing shutdowns and the associated economic losses. Constructed from versatile stainless steel, the tool can be used across various pressures, temperatures, and pipe diameters, and it has applications in a multitude of industries, including oil and gas, chemical processing, water treatment, power generation, marine, and pharmaceutical. The essay underscores the significance of proper maintenance for ensuring the tool’s longevity and offers a step-by-step guide on its operation. It concludes by suggesting further research to enhance the tool’s performance and design.

Understanding the Corrosion Coupon Retrieval Tool and its operation is vital for industries that rely on large-scale pipeline systems. It not only helps identify and measure corrosion but also eliminates the need for costly pipeline shutdowns, thus promising significant economic benefits.

Suggestions for Further Research or Improvements

While the retrieval tool has proven effective in various applications, further research could be beneficial in exploring its performance across different mediums and under extreme conditions. Additionally, advancements in material science could open avenues for the development of components that offer even greater corrosion resistance. Finally, improvements in the tool’s design to further simplify its operation could lead to increased adoption across the industry.

-600x600.jpg)

Ulasan

Durung ana review.