Katrangan

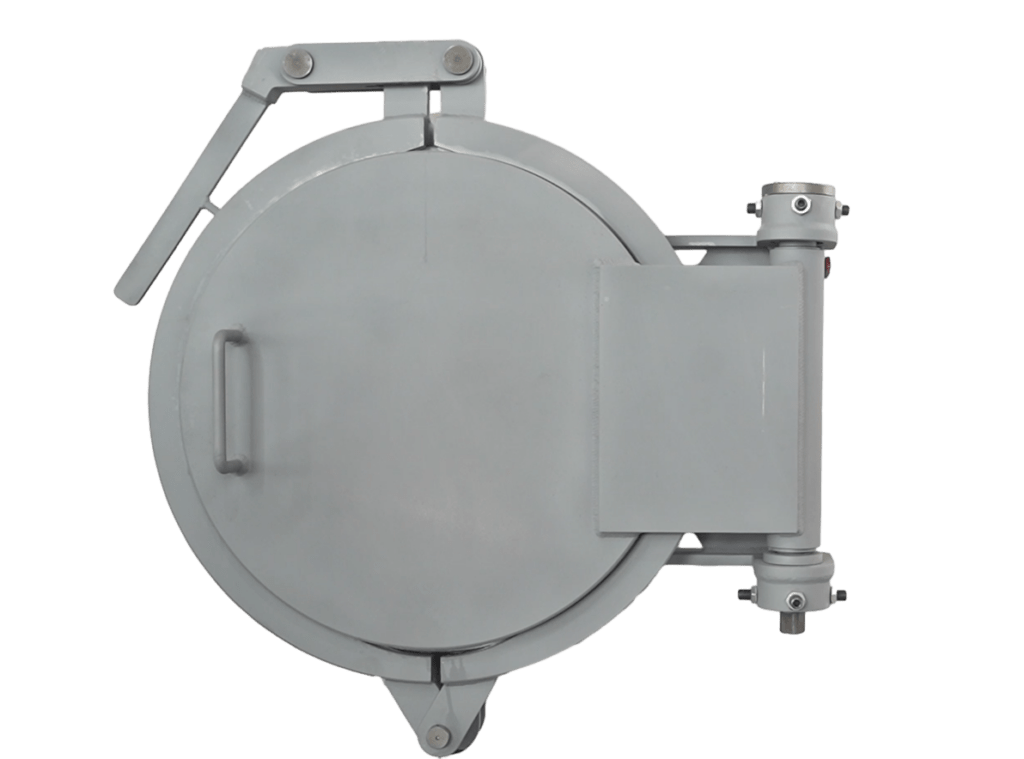

Clamp Ring Bukaan Cepet | ||||

Tekanan Desain | 1.6MPa-30MPa | |||

Tunjangan Korosi | 2 mm | |||

Intensitas Benteng Seismik | 7 drajat | |||

Medium Kerja | Minyak, gas alam, Pulp banyu lan bijih, lsp. | |||

Wektu Bukak | Ing 60s kurang saka 200N | |||

Jinis pambuka | Vertikal utawa Horizontal | |||

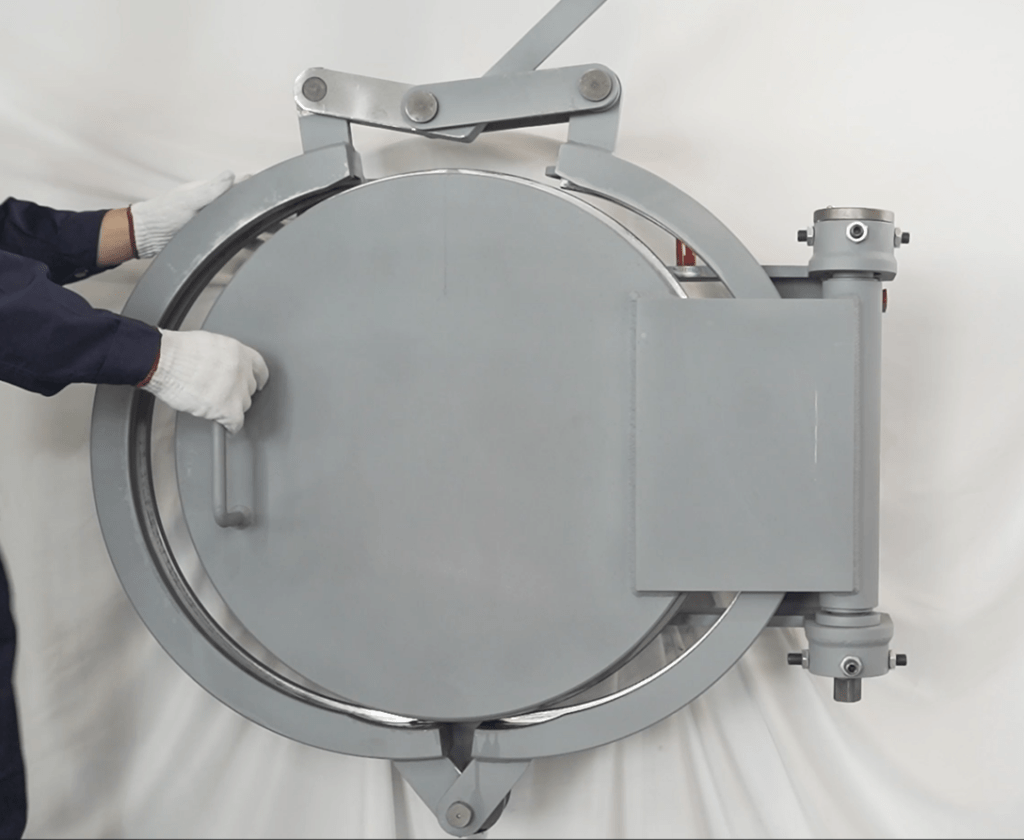

Operasi prosedur iki mbutuhake profesional sing wis ngalami latihan khusus. Kabeh karyawan kudu nggatekake tandha-tandha ing Penutupan Clamp Ring. Penting supaya ora nggunakake alat sing salah, amarga bisa nyebabake karusakan sing ora bisa dibatalake ing sistem rantai safety; contone, siji kudu tau nyoba kanggo mbukak wuta karo Pethel. Langkah sabanjure yaiku ngeculake bolt ventilasi ndhuwur kanthi manual. Yen ana swara utawa lenga wiwit kuthah, iku nuduhake silinder isih ing meksa. Ing kasus kaya mengkono, meksa kudu dirilis, nanging elinga yen port relief meksa internal ora bisa digunakake karo sekrup ventilasi. Sawise tekanan ing silinder dibebasake kanthi lengkap, operator bisa mbukak skru kothong kanthi manual. A chain cilik nyambungake engsel karo plug safety, lan minangka meneng terus unscrewed, bolt ends mboko sithik dawa nganti bolt buntut lan nut krenjang nggawe kontak. Operator banjur nyekel gagang panggeser lan mbukak flange penutupan.

Ing EMT, kita gawé Clamp Ring Closures utamané kanggo aplikasi pipeline, catering kanggo sawetara saka sudhut diameteripun saka 2 "nganti 48" (DN50 kanggo DN1200). Ngenali kabutuhan macem-macem operasi pipa, kita mesthekake penutupan kita ketemu ASME B31.3 / B31.4 / B31.8 / CSA Z662 Cat. Sertifikasi II kanthi faktor desain 0,5 / 0,6. Penutupan Gaya Clamp sing populer nggabungake komponen kualitas unggul, desain sing ramah pangguna, lan prioritas keamanan, menehi solusi sing luar biasa kanggo kabutuhan pipa sampeyan.

Safety Operation lan Maintenance

Operator kudu maca manual operasi iki kanthi teliti kanggo mangerteni struktur lan panggunaan Quick Opening Closure (QOC).

Sadurunge mbukak QOC, mesthekake kanggo mbukak checkscrew nganti tekanan ing tong minyak mudhun menyang nol. Mung banjur sampeyan bisa nerusake menyang langkah sabanjure.

Priksa manawa papan interlocking dipasang kanthi bener nalika nutup tutup tutup. Sawise iki dikonfirmasi, sistem bisa pressurized kanggo nggunakake.

Sajrone operasi, dilarang banget kanggo mencet utawa nabrak bagean lan komponen sing sensitif tekanan.

Sawise saben panggunaan, aplikasi pelumas anti-karat ing kabeh benang sing disambungake, bagean sing muter, lan permukaan sing nutup.

Yen peralatan kasebut ora bakal digunakake kanggo wektu sing suwe, aplikasi pelumas anti-karat ing kabeh benang sing disambungake, bagean puteran, lan permukaan sealing paling sethithik setaun.

Yen QOC dipasang ing lokasi ruangan, fasilitas protèktif tambahan kudu ditambahake.

Ajeg mriksa bagean prewangan tekanan utama QOC, kayata tutup tutup, flange tong minyak, lan ring clamp. Yen sampeyan nemokake karat, retak, utawa masalah liyane, hubungi personel profesional kanggo ngenali sababe lan ngatasi masalah kasebut.

Aplikasi nyata-urip

Clamp Ring Cepet Closures digunakake digunakake ing industri lenga lan gas amarga kemampuan kanggo nyedhiyani sealing cepet lan aman saka prau meksa lan pipelines. Umpamane, dheweke asring dileksanakake kanggo ngluncurake lan nampa jebakan ing operasi pigging pipa. Piranti kasebut mbutuhake bukaan lan tutup sing kerep kanggo nglebokake lan ngekstraksi babi pipa, lan mekanisme penutupan cepet saka desain Clamp Ring kanthi signifikan nyuda downtime, nambah efisiensi, lan nambah safety kanthi nyuda paparan isi pipa.

Saliyane ing sektor minyak lan gas, Clamp Ring Quick Closures nemokake utilitas ing macem-macem industri liyane kanthi lingkungan tekanan dhuwur. Ing industri kimia, digunakake ing reaktor lan prau sing mbutuhake akses reguler kanggo reresik, pangopènan, utawa owah-owahan batch. Ing sektor pembangkit listrik, dheweke digunakake ing drum boiler lan penukar panas kanggo nggampangake akses gampang kanggo mriksa lan pangopènan. Industri panganan lan omben-omben uga digunakake ing prau tekanan kanggo tujuan sanitasi. Kesederhanaan, linuwih, lan kacepetan operasi sing ditawakake Clamp Ring Quick Closures nggawe pilihan sing disenengi ing macem-macem aplikasi industri sing mbutuhake akses sing kerep lan aman menyang sistem tekanan dhuwur.

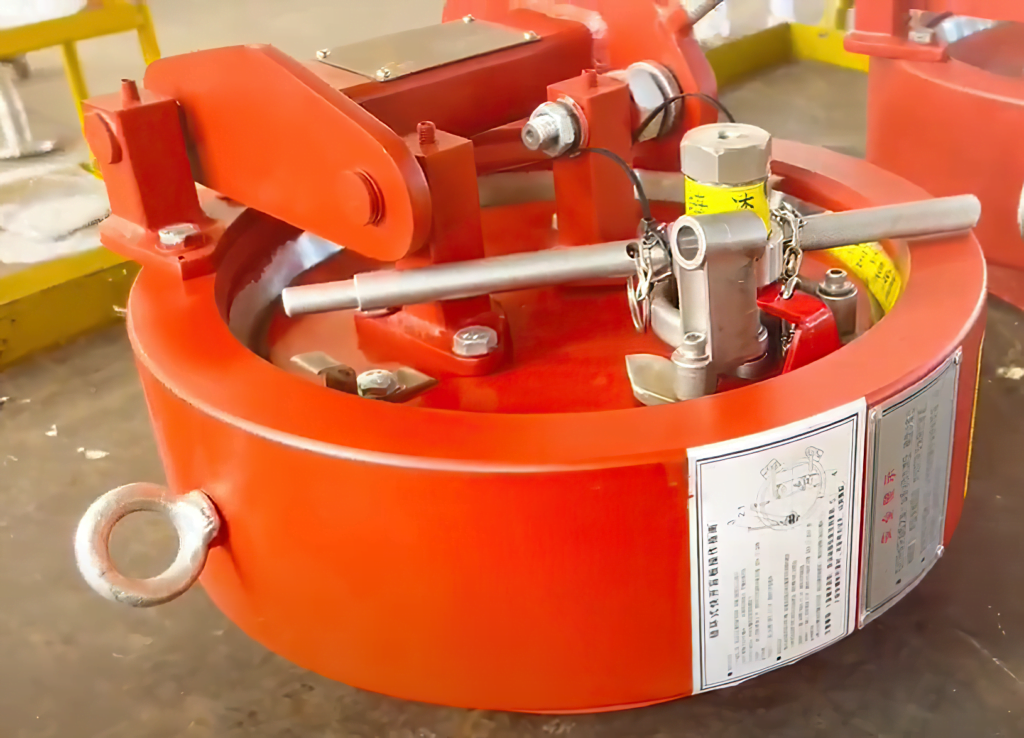

Jinis Penutupan Cepet liyane

Kejabi Penutupan Clamp Ring, kita uga ngasilake rong jinis Penutupan Bukaan Cepet: Penutupan Bukaan Cepet Dering Kunci lan Penutupan Bukaan Cepet Bayonet. Saben wong duwe rong jinis: jinis vertikal lan jinis horisontal. Miturut posisi pipa, tutup bukaan cepet sing beda bisa dipilih. Lock Ring Cepet Opening Closure nawakake solusi sing aman lan efisien kanggo kabutuhan akses sing kerep, nyedhiyakake segel sing aman lan mekanisme bukaan sing gampang. The Bayonet Quick Opening Closure, ing sisih liya, nduweni desain sing prasaja lan mantep sing cocog kanggo aplikasi tekanan dhuwur, njamin linuwih lan daya tahan sanajan ing kahanan sing nuntut. Opsi loro kasebut menehi kaluwihan unik, nambah efisiensi lan safety operasional. Yen sampeyan mbutuhake pitulungan, aja ragu-ragu hubungi kita. Kita setya nyedhiyakake layanan paling dhuwur sing cocog karo kabutuhan khusus sampeyan.

Ringkesan

Kesimpulane, Penutupan Bukaan Cepet Bandlock lan Penutupan Cepet Clamp Ring minangka alat sing penting ing macem-macem industri, utamane sektor minyak lan gas. Dheweke nyedhiyakake cara sing cepet, aman, lan efisien kanggo nutup prau tekanan lan pipa, uga menehi akses gampang kanggo pangopènan, pamriksa, reresik, lan kabutuhan operasional liyane.

Parameter desain lan operasional, uga prosedur safety, nggambarake perhatian sing sregep kanggo rincian lan penekanan sing kuat ing daya tahan, safety, lan efisiensi. Iki kabukten ing pedoman operasi lan pangopènan safety sing ketat, sing nandheske pendekatan proaktif kanggo njaga fungsi lan safety piranti.

Kajaba iku, aplikasi nyata ing macem-macem sektor industri luwih negesake fleksibilitas lan kegunaane. Apa nalika ngluncurake lan nampa jebakan ing operasi pigging pipa utawa mbisakake akses reguler menyang reaktor lan prau ing industri kimia, penutupan kasebut wis kabukten minangka komponen sing dipercaya lan penting ing lingkungan tekanan tinggi.

Penekanan ing latihan profesional kanggo operator, pedoman tliti kanggo operasi aman, lan kabutuhan kanggo pangopènan biasa kabeh nyorot prasetya kanggo safety lan efisiensi operasional. Nalika kita terus berinovasi lan maju ing proses industri, peran alat sing efisien, aman, lan serba guna amarga penutupan bukaan sing cepet iki mesthi bakal tetep penting.

Ulasan

Durung ana review.