Katrangan

Pambuka kanggo Kimia Injeksi Quill Akses Pas

Pambuka kanggo Kimia Injeksi Quill Akses Pas

Perlengkapan Quills Access nduwe peran penting ing pangiriman bahan kimia sing aman lan efisien menyang sistem pipa. Sambungan iki digawe saka bahan sealing kanthi kinerja dhuwur sing nyegah bocor sanajan ing tekanan dhuwur, njamin keamanan lan efisiensi operasional maksimal.

Salah sawijining fitur utama fitting pipa Quill Access yaiku pompa injeksi cair sing dibangun. Sistem kasebut ngidini cairan kimia disuntikake kanthi tepat menyang pipa liwat katup khusus lan pipa sing nyambungake. Utawa, bisa gampang ngekstrak media ing njero pipa menyang wadhah sampling, nyedhiyakake solusi universal kanggo macem-macem proses pipa.

Yen sampeyan duwe pitakon utawa wawasan liyane babagan tabung injeksi kimia lan aplikasie, tim profesional kita siyap nulungi sampeyan. Ngandelake keahlian kita kanggo nuntun sampeyan babagan nuansa komponen pipa penting iki.

Bahan insulasi suhu sing luwih dhuwur yaiku:

Teflon: 500″F (260″C) Rulon: 550″F (288″C)

Keramik: 1472″F (800″C)

| Model | ||||||||||||||||||||||||||||

LAN | Pas Akses Quills Injeksi Kimia | |||||||||||||||||||||||||||

| -Kode | Plug | |||||||||||||||||||||||||||

| Pxxx | Jinis | Bahan | Bahan Sealing | |||||||||||||||||||||||||

| 0 | Ora Panjaluk | 0 | CS | 0 | Ora Panjaluk | |||||||||||||||||||||||

| 1 | Body Plug Hollow | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Kemasan Utama | |||||||||||||||||||||

| 2 | Badan Plug Solid | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Kode | Kacang Injeksi | |||||||||||||||||||||||||||

| Nxx | Ukuran sambungan | Bahan | ||||||||||||||||||||||||||

| 0 | yaiku Ora Ana Panjaluk | 0 | yaiku CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4" | 1 | yaiku 316SS | 3 | yaiku DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | yaiku 316LSS | 4 | yaiku INCONEL | |||||||||||||||||||||||

| – Kode | Tabung Injeksi Kab | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Ukuran sambungan | Bahan | Nozzle | Ukuran garis (x″) | ||||||||||||||||||||||||

| 0 | Ora Panjaluk | 0 | CS | 0 | yaiku Ora Ana Panjaluk | Posisi sing paling efektif kanggo injeksi umume ing tengah pipa | ||||||||||||||||||||||

| 1 | i.e. 1/4" | 1 | yaiku 316SS | 1 | yaiku Bukak | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | yaiku 316LSS | 2 | yaiku Quill | |||||||||||||||||||||||

| 3 | yaiku DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | yaiku INCONEL | |||||||||||||||||||||||||||

| – Kode | Puting lan Katup (utawa End Flange) saka Tee | |||||||||||||||||||||||||||

| Txx | Ukuran sambungan | Bahan | ||||||||||||||||||||||||||

| 0 | yaiku Ora Ana Panjaluk | 0 | yaiku CS | |||||||||||||||||||||||||

| 1 | yaiku 1/4″ puting susu | a | yaiku 1/4″Puting lan Katup | 1 | yaiku 316SS | |||||||||||||||||||||||

| 2 | yaiku 1/2″ puting susu | b | yaiku 1/2″ Puting lan Katup | 2 | yaiku 316LSS | |||||||||||||||||||||||

| 3 | yaiku 3/4″ puting susu | c | yaiku 3/4″Puting lan Katup | 3 | yaiku D SS | |||||||||||||||||||||||

| 4 | yaiku 1″ puting susu | d | yaiku 1″Puting lan Katup | 4 | yaiku INCONEL | |||||||||||||||||||||||

| 5 | yaiku 1/4″ Flange | e | yaiku 1/4″ Puting ujung Flange | |||||||||||||||||||||||||

| 6 | yaiku 1/2″ Flange | f | yaiku 1/2″ Puting ujung Flange | |||||||||||||||||||||||||

| 7 | yaiku 3/4″ Flange | g | yaiku 3/4″ Puting ujung Flange | |||||||||||||||||||||||||

| 8 | yaiku 1″Flange | h | yaiku 1″ Puting ujung Flange | |||||||||||||||||||||||||

P221: contone. Solid Plug Body ing 316LSS Viton O-Ring lan PTFE kemasan Utama N12: contone, injeksi Nut Ukuran Sambungan 1/4″ lan Bahan 316LSS, S122: contone. injeksi Ukuran sambungan tabung yaiku 1/4 ″ lan materi yaiku 316LSS. Jenis nozzle yaiku quills L4″: Kanggo pipa 4″. T22: Ukuran Sambungan Puting Tee 1/2″, Bahan Puting 316LSS | ||||||||||||||||||||||||||||

Komponen injeksi kimia minangka alat penting kanggo industri minyak lan gas. Operator nggunakake komponen kasebut kanggo nyuntikake bahan kimia menyang pipa tekanan dhuwur sing nggawa cairan produksi, banyu laut, lan macem-macem media liyane. Proses iki nduweni sawetara tujuan, kayata ningkatake efisiensi operasional peralatan pangolahan sing gegandhengan, nglindhungi peralatan lan pipa sumur, lan ndawakake umur layanan peralatan kasebut.

Chemical injection tubes have been widely used in the global oil extraction and processing industry. In oil field production, chemical injection pump systems mainly inject methanol or ethylene glycol into the fluid upstream of the nozzle manifold. This action prevents the fluid from forming frozen hydrates due to a drop in pressure. At the same time, the reliability of the surface test system and the upper and lower pressure drop range of the nozzle are improved, so that the oil (gas) well can resume normal operation.

jeneng | Pas Akses Quills Injeksi Kimia | |

| Bahan | Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, lan uga Inconel 625 | |

| Suhu operasi | -20~+120℃ | |

| Fitur | Pisanan, gampang digunakake | |

| Second, long life and high accuracy | ||

| At last, low cost and high efficiency | ||

| pambayaran | TT/LC | |

| Kaluwihan | First, lightweight and flexible | |

| Second, excellent injection efficiency | ||

| Pungkasan, pelacakan lokasi sing akurat |

This ensures safety. Ing industri proses, kita nggunakake sistem injeksi kimia. Iki ngidini bahan kimia cair disuntikake kanthi tepat menyang cairan sing disuntikake maneh utawa disuntikake kanthi tekanan dhuwur utawa sithik. Ana pirang-pirang jinis agen kimia sing disuntikake menyang solusi, biasane kalebu metanol, etilena glikol, pengawet, lan deoxidizer. Ana uga aditif adi pengeboran (soda kaustik lan polimer cair) lan defoamer. Sistem pompa injeksi kimia uga bisa digunakake kanggo ngirim feedstock sacara kuantitatif menyang reaktor tekanan dhuwur.

Sistem pompa injeksi bahan bakar kimia dumadi saka telung bagean: tekanan hidrolik ultra-dhuwur, mekanis lan nyopir. Bagean hidrolik nyedhiyakake sumber tekanan ultra-dhuwur kanggo sistem injeksi kimia. Bagean udara nyopir nguwasani kabeh sistem. Tekanan kerja maksimum sistem injeksi kimia yaiku 1050bar. Sirkuit tegangan dhuwur dilengkapi piranti proteksi nyaring lan overvoltage. Kanthi level lenga lan fungsi tampilan tekanan. Uga nduweni fungsi nahan tekanan lan ngeculake materi. Bagean udara nyopir nguwasani kabeh sistem. Tekanan operasi maksimum sirkuit udara nyopir yaiku 10bar. Sirkuit udara drive dilengkapi piranti proteksi nyaring lan overvoltage. Kanthi fungsi tampilan tekanan. Uga nduweni fungsi pangaturan tekanan.

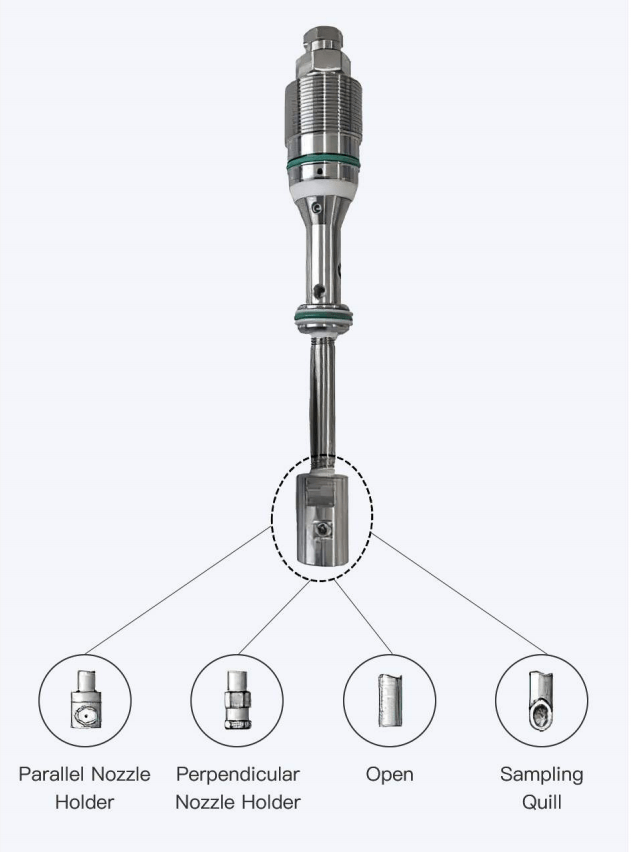

Pambuka kanggo Jinis Nozzles ing Quills Injeksi Kimia

Quill injeksi kimia dilengkapi karo papat jinis muncung, saben dirancang kanggo fungsi lan tujuan tartamtu. Ngerteni macem-macem jinis muncung iki bisa mbantu ngoptimalake panggunaan ing macem-macem aplikasi. Saben jinis muncung nduweni kaluwihan lan aplikasi sing unik, saengga bisa nggedhekake panggunaan tabung bulu injeksi kimia ing industri minyak lan gas.

Nozel paralel: Minangka jeneng tabet, nozzles podo dirancang kanggo podo karo arah aliran ing pipo. Iki minangka cara sing cocog kanggo nyuntikake bahan kimia lan langsung gabung karo aliran pipa.

Nozzle vertikal: Minangka gantos kanggo nozzles podo, nozzles vertikal ing tengen ngarepke kanggo aliran pipe. Iki ngidini kanggo injeksi kimia liyane buyar, mundhakaken isi pipe saka dicampur.

Nozzle mbukak: Jinis muncung iki ora duwe struktur watesan ing mburi wulu. The open nozzle allows chemicals to flow freely and unrestricted into the pipe, providing a large volume injection.

Sampling quill: The sampling pen is used to extract samples from the pipe instead of injecting chemicals into the pipe. This is essential for testing and quality control as it allows operators to monitor and evaluate the chemical composition in the pipeline.

Layanan Kita

Layanan Kita

We offer a wide range of chemical injection pipe fittings to meet specific requirements. Please do not hesitate to contact us to find the solution that best suits your needs.

In order to reflect the high quality of our products, we provide our customers with the option to request samples.

We pride ourselves on providing prompt service to our customers. Tim kita siyap menehi umpan balik langsung lan ngatasi pitakon sampeyan.

Kita usaha kanggo nyedhiyani wektu pangiriman paling cepet kanggo mesthekake yen sampeyan nampa pesenan ing proses pas wektune. Dhukungan online kita kasedhiya 24 jam dina, 7 dina seminggu.

Packaging & Delivery

Produk kita dikemas ing CASES, sing nduweni keuntungan ing ngisor iki:

- Padha entheng, nampilaken garis resik, nyediakake jampel, lan gumunggung kekuatan dhuwur tanpa rentan kanggo deformasi.

- Padha ngilangi kabutuhan fumigasi, nggawe proses pengiriman luwih efisien.

Komitmen kita yaiku ngirim kelengkapan akses quills injeksi kimia sing paling apik kanthi cepet lan efisien, kanthi prioritas kepuasan pelanggan sawayah-wayah.

Pambuka kanggo Kimia Injeksi Quill Akses Pas

Pambuka kanggo Kimia Injeksi Quill Akses Pas

Ulasan

Durung ana review.