Deskripsi

Perkenalan

Penutupan Buka Cepat Bejana Tekan adalah konstruksi penahan tekanan yang dimaksudkan untuk menyediakan akses ke tangki tekanan dan saluran pipa. Penutupan Cepat kami menawarkan akses cepat dan aman ke bejana tekan dan saluran pipa. Mereka dapat digunakan dalam aplikasi horizontal, vertikal, miring, atau menurun dan dibuat sesuai dengan standar desain internasional. Sesuai permintaan klien, kami menyediakan penutup penjepit, bayonet, dan kunci cincin. “Penutupan dengan penggerakan cepat atau pembukaan cepat adalah penutupan yang memungkinkan akses jauh lebih cepat ke ruang isi bejana tekan dibandingkan yang diharapkan dengan sambungan flensa baut standar,” menurut Approved Design ASME VIII Div. 1. Seiring dengan stempel kode ASME U, persyaratan kode bejana tekan tambahan seperti ASME VIII Div. 2 dan PD5500 juga dapat dipenuhi. Penutupan pembukaan cepat telah menjalani pemeriksaan toko secara menyeluruh oleh Inspektur Resmi ASME, sesuai dengan penandaan kode. Penutupan pembukaan cepat sering digunakan dalam wadah filter, saringan, dan pemisah.

Portofolio kami yang luas mencakup tutup yang dapat dibuka dengan cepat untuk bejana tekan yang dihitung, dirancang, dan dibuat sesuai spesifikasi pelanggan. Setiap penutupan adalah produksi satu unit atau yang dipesan lebih dahulu; dari A hingga Z, kami bekerja dengan pelanggan kami untuk menentukan perhitungan, bahan yang akan digunakan, desain, dan persetujuan. Tentu saja, kami mematuhi standar dan hukum umum internasional dan Eropa. Berdasarkan kriteria yang ditetapkan dan spesifikasi tambahan, penutupan cepat kami dilengkapi dengan semua perangkat keselamatan yang diperlukan. Dengan penggunaan gadget tersebut, penutupnya tidak bisa dibuka secara paksa.

Jenis Penutupan Buka Cepat

Ada beberapa jenis penutupan cepat terbuka yang tersedia, masing-masing dengan fitur dan manfaat uniknya. Yang paling umum digunakan termasuk penutup Lock Ring, Threaded, dan Clamp.

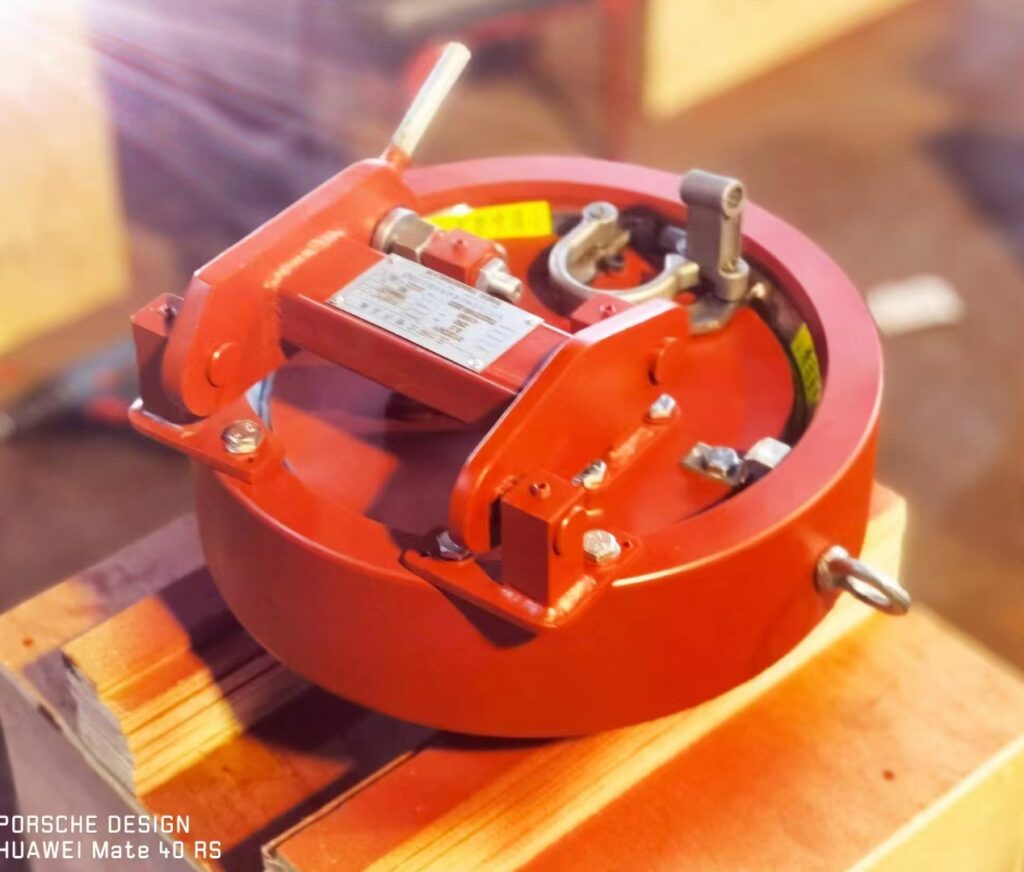

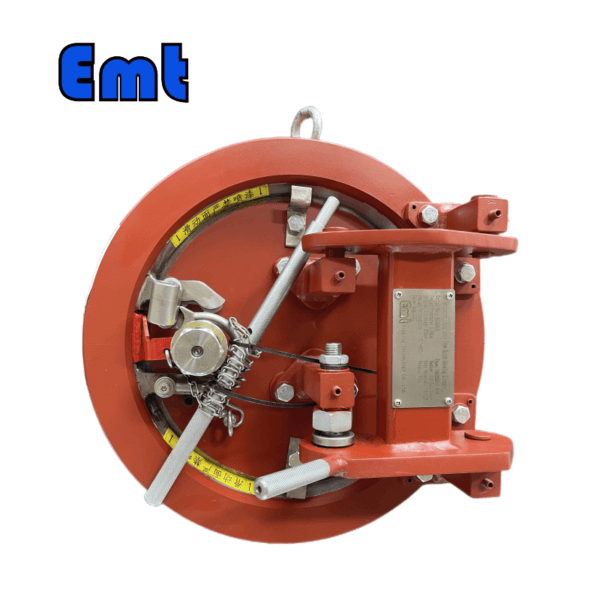

Penutupan Cincin Kunci

Penutupan Cincin Pengunci biasanya digunakan untuk bejana tekan dan pipa berdiameter lebih besar. Mereka memberikan akses yang mudah dan penyegelan yang aman dengan mengunci cincin berengsel di tempatnya, yang menahan pintu penutup dengan aman.

Kelebihan: Penutupan Cincin Pengunci kuat, aman, dan dapat mengakomodasi tekanan tinggi dan diameter besar. Biasanya mudah dioperasikan, bahkan dalam kondisi beban berat.

Kontra: Penutupan ini bisa lebih mahal karena konstruksinya yang berat. Selain itu, alat tersebut mungkin memerlukan lebih banyak ruang untuk pengoperasiannya, yang dapat menjadi kerugian jika digunakan di ruang terbatas.

Penutupan Berulir

Penutupan Berulir melibatkan pintu berulir yang disekrupkan ke bejana tekan. Mereka biasanya digunakan untuk bejana berdiameter lebih kecil dimana tekanannya relatif rendah.

Kelebihan: Penutupan berulir sederhana, hemat biaya, dan mudah dioperasikan. Biasanya tidak memerlukan alat khusus untuk membuka atau menutup.

Kontra: Kelemahan utamanya adalah memerlukan waktu lama untuk membuka dan menutup, terutama pada diameter yang lebih besar. Selain itu, benangnya mungkin aus seiring waktu sehingga memerlukan perawatan atau penggantian.

Penutupan Penjepit

Penutupan Penjepit menggunakan mekanisme penjepit untuk menahan pintu pada tempatnya. Ini sering digunakan dalam bejana bertekanan berukuran sedang, memberikan keseimbangan yang baik antara kemudahan penggunaan dan penyegelan yang aman.

Kelebihan: Penutupan penjepit umumnya menawarkan pembukaan dan penutupan yang lebih cepat dibandingkan penutupan berulir. Penutup ini juga lebih kecil kemungkinannya untuk mengalami keausan dibandingkan dengan penutup berulir.

Kontra: Meskipun lebih cepat daripada penutupan berulir, penutupan penjepit biasanya lebih lambat untuk membuka dan menutup dibandingkan penutupan cincin pengunci. Mereka mungkin juga tidak cocok untuk tekanan yang sangat tinggi atau diameter yang besar.

Memilih Tipe yang Tepat

Memilih penutupan cepat terbuka yang tepat bergantung pada beberapa faktor. Ukuran dan tekanan bejana tekan merupakan pertimbangan penting. Untuk bejana yang lebih besar dengan tekanan tinggi, penutupan cincin pengunci mungkin merupakan pilihan terbaik. Untuk bejana yang lebih kecil dan bertekanan rendah, penutup berulir bisa menjadi pilihan yang hemat biaya. Penutupan klem mungkin ideal untuk kapal berukuran sedang yang memerlukan keseimbangan antara kecepatan, keamanan, dan biaya.

Pertimbangan operasional juga penting. Jika akses cepat adalah prioritas, penutupan cincin kunci atau klem mungkin lebih baik. Jika biaya adalah faktor kuncinya, penutupan berulir mungkin merupakan pilihan terbaik. Ruang yang tersedia untuk pengoperasian penutupan juga dapat mempengaruhi keputusan.

Lastly, compliance with design codes and standards is essential. All closures should meet relevant international design codes, and where necessary, should carry appropriate certification such as ASME U code stamping, or EN 10204 3.1 & EN 10204 3.2.

Kesimpulannya, tidak ada solusi universal dalam hal penutupan terbuka cepat. Pilihan terbaik akan bergantung pada persyaratan spesifik dan batasan aplikasi.

Pertimbangan Keamanan untuk Penutupan Buka Cepat Bejana Tekan

Seperti halnya peralatan operasional lainnya, keselamatan adalah hal terpenting dalam penggunaan penutupan cepat terbuka. Perangkat ini menggabungkan beberapa fitur keselamatan dan memerlukan kepatuhan terhadap tindakan pencegahan tertentu dan standar industri untuk memastikan pengoperasian yang aman.

Fitur Keamanan

Penutupan terbuka cepat sering kali menyertakan mekanisme keselamatan bawaan. Fitur umumnya adalah Perangkat Peringatan Tekanan, yang mengingatkan operator akan adanya sisa tekanan di dalam bejana. Hal ini memastikan operator tidak secara tidak sengaja mencoba membuka penutup sebelum seluruh tekanan dihilangkan, sehingga mencegah potensi kecelakaan.

Penguncian mekanis adalah fitur keselamatan penting lainnya dalam banyak penutupan cepat terbuka. Mekanisme ini memastikan bahwa penutupan tetap pada tempatnya selama pengoperasian, mencegah pembukaan yang tidak disengaja di bawah tekanan.

Tindakan Pencegahan Saat Menggunakan Penutupan Buka Cepat

Operator harus selalu memastikan bahwa semua tekanan telah dilepaskan sepenuhnya sebelum mencoba membuka penutupan. Perangkat Peringatan Tekanan adalah alat yang berharga di sini, namun operator juga harus dilatih untuk memastikan pelepasan tekanan melalui cara lain.

Pemeliharaan penutupan yang tepat juga penting. Inspeksi rutin dan penggantian komponen yang aus atau rusak secara tepat waktu dapat mencegah kegagalan penutupan selama pengoperasian.

Terakhir, operator harus terlatih dengan baik dalam prosedur yang benar untuk membuka dan menutup perangkat. Hal ini mencakup pemahaman cara menggunakan alat apa pun yang diperlukan dan cara memastikan bahwa penutup telah tersegel dengan benar setelah penutupan.

Kepatuhan terhadap Standar dan Peraturan Industri

Penutupan buka cepat harus memenuhi persyaratan kode desain industri yang relevan, seperti ASME VIII Div. 1, Divisi ASME VIII. 2, dan PD5500. Kepatuhan terhadap standar-standar ini memverifikasi bahwa penutupan telah dirancang dan dibangun untuk menahan tekanan yang akan dihadapi selama pengoperasian.

Banyak penutupan cepat terbuka juga membawa cap kode ASME U. Stempel ini menegaskan bahwa penutupan tersebut telah menjalani pemeriksaan toko yang ketat oleh Inspektur Resmi ASME, yang selanjutnya menyatakan keamanannya.

Kesimpulan

Portofolio kami yang luas mencakup tutup yang dapat dibuka dengan cepat untuk bejana tekan yang dihitung, dirancang, dan dibuat sesuai spesifikasi pelanggan.

Setiap penutupan adalah produksi satu unit atau yang dipesan lebih dahulu; dari A hingga Z, kami bekerja dengan pelanggan kami untuk menentukan perhitungan, bahan yang akan digunakan, desain, dan persetujuan. Tentu saja, kami mematuhi standar dan hukum umum internasional dan Eropa.

Berdasarkan kriteria yang ditetapkan dan spesifikasi tambahan, penutupan cepat kami dilengkapi dengan semua perangkat keselamatan yang diperlukan. Dengan penggunaan gadget tersebut, penutupnya tidak bisa dibuka secara paksa.

However, the selection of closure is not simply based on the vessel’s physical characteristics. Cost, accessibility speed, operational concerns, and space restrictions are all crucial aspects of decision-making. Additionally, the reliability and safety of the closure are ensured by adherence to international design codes and certifications, such as ASME U code stamping or EN 10204 3.1 & EN 10204 3.2.

Keselamatan, yang paling penting dalam proses ini, ditangani melalui mekanisme keselamatan bawaan seperti sistem penguncian mekanis dan perangkat peringatan tekanan. Karakteristik ini menambah keselamatan keseluruhan penutupan cepat terbuka serta perlindungan penting, pemeliharaan yang konsisten, dan pelatihan operator yang tepat.

Ulasan

Belum ada ulasan.