Deskripsi

Pengenalan penutupan tong babi

Penutupan Pig Barrel berfungsi sebagai "pintu" untuk akses mudah di dalam peluncur dan penerima.

Keamanan penutupan

Pintu peluncur dan penerima babi adalah penutupan akhir. Mereka dilas ke laras, mencocokkan bahan dan ketebalan laras. Penutupan akhir pembukaan yang cepat sering datang dengan interlock keamanan. Interlock ini memblokir bukaan di bawah tekanan untuk keselamatan.

Penutupan harus cocok dengan diameter bagian dalam barel peralatan dan mempertahankan jarak jauh. Kecocokan sambungan pantat harus memenuhi standar. Sumbu tengah penutupan harus selaras dengan sumbu laras. Sebelum penyelarasan, pilih jenis pengelasan untuk penutupan. Untuk pengelasan dua sisi, lepaskan penutup kepala. Untuk pengelasan sisi tunggal, cukup lepaskan cincin penyegelan, tinggalkan penutup kepala di tempatnya.

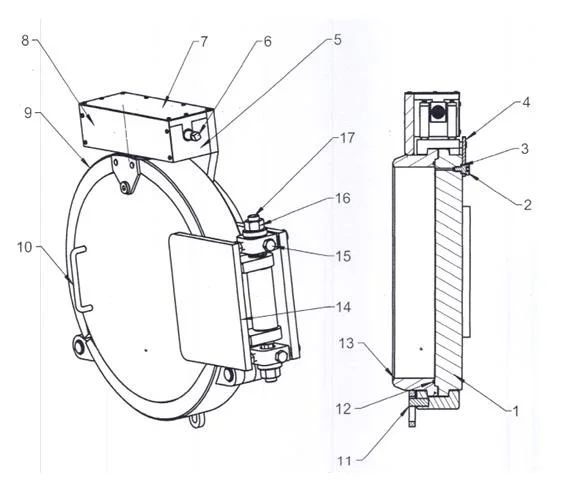

Komponen

No. 1: penutup penutupan

No. 2: Periksa sekrup

No. 3: Cincin penyegelan asuransi

No. 4: Papan yang saling terkait

No. 5: Panduan Sekrup Saddle

No. 6: Mekanisme Pembukaan dan Penutupan (sekrup pemandu)

No. 7: papan penutup atas

No. 8: Papan penutup depan

9: cincin penjepit

No.10: Pegangan

11: Mekanisme Panduan Cincin Penjepit

No. 12: Cincin penyegelan utama

No. 13: Barrel flange

No. 14: Front folder

No. 15: Adjust bolts (front &back, left & right)

No. 16: Adjust nuts (top &down)

No. 17: Vertical shaft

Risk Identification And Mitigation Measures | ||

| Hazard factors | Hazard Sequences | Risk mitigation measures |

| Mechanical injury | Personal injury; casualties | Strengthen work supervision; wear labor protective articles; Your body should not face the Pig Barrel Closure, you should stand on the side. |

| Natural gas poisoning, asphyxia | Casualties | Strengthen the detection of harmful gas concentration; wear a gas mask or breathing apparatus. |

| Fire and explosion | Personal injury; property damage | Strengthen work supervision; detect the concentration of the natural gas; waer labor protective articles; use explosion-proof tools; control all fire sources; mencegah pembakaran spontan ferrous sulfida dalam wadah; mengadopsi operasi basah. |

Pembongkaran Qoc

A. Lepaskan gerbang No. 2; Lepaskan cincin segel No. 3; Lepaskan pelat interlock No. 4;

B. No. 6 Mekanisme pembukaan dan penutupan, terbuka No. 9 klem longgar ke posisi;

C. Tahan pegangan No. 10, lepaskan penutup penutup No. 1 dengan lembut, dan keluarkan cincin segel utama No. 12;

D. Lepaskan mur bergerak No. 16, lepaskan poros vertikal No. 17, tempatkan penjepit depan No. 14 dan penutup No. 2 dalam posisi yang aman, dan perhatikan permukaan penyegelan pelindung.

e. Lepaskan Penutup Depan No. 8, Penutup Atas No. 7, dan Rod Pemandu No. 5. Lepaskan cincin klem No. 9 dan mekanisme pembukaan dan penutupan No. 6 ke posisi yang aman.

Proses dasar operasi pipa perlu diimplementasikan sebelum operasi:

1. Pipa melalui garis bola.

Setelah menyelesaikan pembangunan pipa gas alam, hal pertama yang harus dilakukan adalah menyapu pipa. Tujuan dan signifikansi: Lepaskan tanah, terak las, batu, rumput, dan puing -puing lainnya di dalam pipa sehingga dalam keadaan bersih. Penggunaan yang Disarankan: Babi Jenis Kuas Lurus.

Berjalan dua arah, efek pembersihan yang baik, kemampuan passing yang baik, dan penyegelan yang baik mencirikannya. Membawa sikat kawat dapat menghilangkan karat di dinding bagian dalam pipa, las slag, dan melakukan fungsi lainnya. Sehingga pipa lebih bersih setelah pembersihan bola. Standar Cina menetapkan bahwa jumlah umum operan tidak kurang dari 2 kali; Kami menyarankan agar operasi proses dalam tautan ini adalah 2 hingga 4 kali.

2. Pengukuran Diameter Pipa.

Penutupan harus cocok dengan diameter bagian dalam barel peralatan dan mempertahankan jarak jauh. Kecocokan sambungan pantat harus memenuhi standar. Sumbu tengah penutupan harus selaras dengan sumbu laras. Sebelum penyelarasan, pilih jenis pengelasan untuk penutupan. Untuk pengelasan dua sisi, lepaskan penutup kepala. Untuk pengelasan sisi tunggal, cukup lepaskan cincin penyegelan, tinggalkan penutup kepala di tempatnya.

3. Injeksi air pipa.

Setelah pengukuran diameter pipa memenuhi syarat, uji tekanan pipa dapat dilakukan. Media uji tekanan umumnya air bersih. Kepala uji tekanan dilas di kedua ujung pipa untuk menyuntikkan air ke dalam pipa. Sebelum injeksi air, bola babi bundar dapat ditempatkan di dalam pipa. Air dapat mendorong bola babi melingkar untuk berjalan sehingga udara dalam pipa terus -menerus habis. Ini kondusif untuk stabilitas uji tekanan.

4. Tekanan injeksi pipa, tes tekanan, uji tekanan yang ketat.

Setelah air dalam pipa diisi, pompa uji tekanan dapat melakukan uji penurunan tekanan injeksi air, uji tekanan yang kuat, dan uji penyesuaian tekanan ketat sampai memenuhi syarat.

5. PENGEMBALIAN AIR PIPA.

Setelah uji tekanan pipa memenuhi syarat, pekerjaan penghilangan air pada pipa dapat dilakukan. Hubungkan dua ujung pipa, terima silinder servis, mulai babi, dan terapkan operasi pengangkutan pipa dan pelepasan air. Penggunaan yang Disarankan: Babi lurus. Jumlah operasi penghilangan air umumnya 3-5 kali.

6. Pengeringan awal pipa.

Setelah menyelesaikan operasi pelepasan air pada pipa lurus, perlu untuk melakukan pengeringan pipa awal. Secara umum, bola pengeringan spons polieter digunakan, yang dapat diluncurkan secara terus menerus, dan berapa kali disarankan untuk mencapai 30-50.

7. Pengeringan dalam pipa.

Metode umum pengeringan kedalaman pipa adalah menggunakan pengeringan udara kering, pengeringan nitrogen, dan pengeringan vakum. Untuk pipa gas alam, pengeringan udara kering dan pengeringan nitrogen umumnya digunakan, yang harus dikombinasikan dengan kondisi lokal dan kondisi aktual.

8. Perlindungan Penggantian Nitrogen dari Pipa.

Setelah operasi proses 1-7 di atas, pipa dilengkapi dengan perlindungan nitrogen, kandungan nitrogen akhir pada akhir pipa ≧ 98% memenuhi syarat, dan penyimpanan tekanan mikro umumnya 0,05 MPa.

Ulasan

Belum ada ulasan.