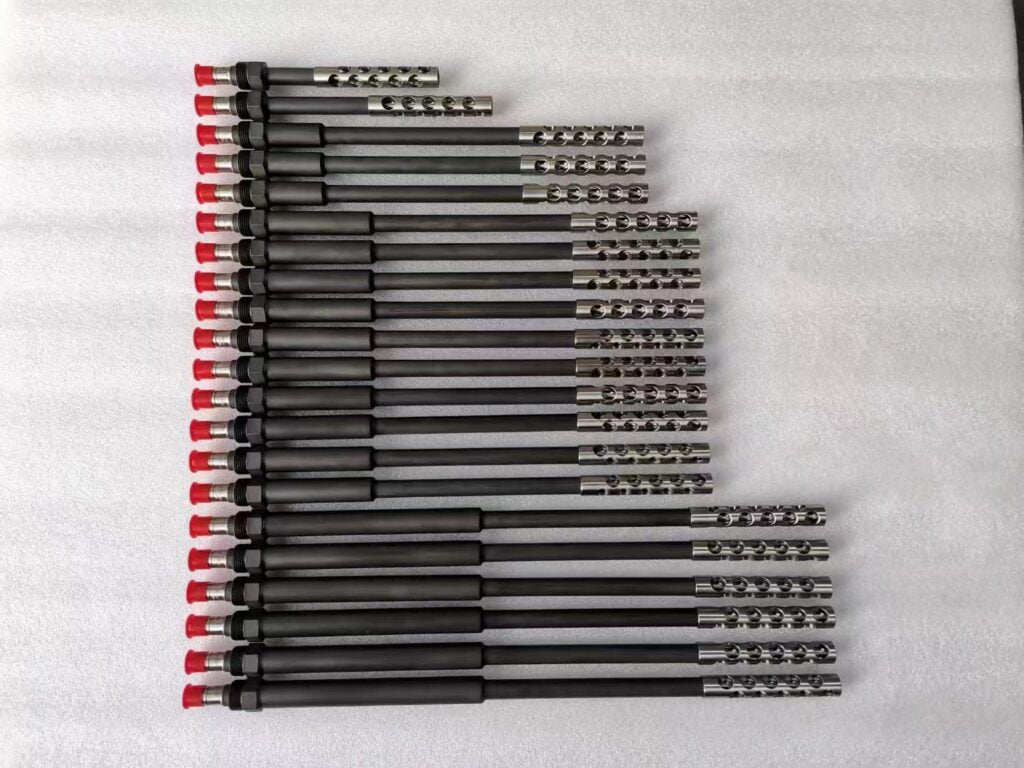

Deskripsi

Perkenalan

In the high-stakes world of oil and gas pipeline management, the margin for error is razor-thin. One overlooked detail can lead to costly repairs, environmental damage, and even catastrophic failure. That’s where erosion probes come into play—a seemingly small component that plays a monumental role in ensuring the integrity and longevity of your pipeline system. Choosing the right erosion probe isn’t just a technical decision; it’s a strategic investment in the safety, efficiency, and future of your operations.

In the complex ecosystem of oil and gas pipelines, erosion probes serve as the unsung heroes. These vital instruments are the frontline defense against pipeline wear and tear, helping to detect early signs of erosion that could otherwise lead to devastating leaks or failures. By continuously monitoring the pipeline’s condition, erosion probes provide invaluable data that informs maintenance decisions, ensures regulatory compliance, and ultimately safeguards both human lives and environmental integrity. Simply put, they are an indispensable tool for proactive and effective pipeline management.

Choosing the right erosion probe is more than a one-time decision; it’s a long-term investment in the health and efficiency of your pipeline system. The right probe not only provides accurate and timely data but also minimizes the frequency of manual inspections, reducing operational costs. Over time, this translates to fewer disruptions, less wear and tear, and a significantly lower risk of costly failures or environmental incidents. In essence, the right erosion probe acts as a long-term partner in your quest for operational excellence, offering a return on investment that far outweighs the initial cost.

The Challenges of Pipeline Erosion

Erosion in oil and gas pipelines is a pervasive issue that can manifest in various ways, each with its own set of challenges and risks. One of the most common forms is internal erosion, often caused by the high-speed flow of abrasive particles like sand, rust, or scale. Over time, these particles can wear down the internal walls of the pipeline, leading to thinning and eventually, leaks or ruptures.

Another issue is turbulent flow erosion, which occurs when the fluid’s velocity changes abruptly due to bends, fittings, or changes in pipeline diameter. This can cause localized wear and tear, making certain sections of the pipeline more susceptible to failure.

Corrosive erosion is also a significant concern, especially in pipelines that transport sour crude or natural gas containing corrosive elements like hydrogen sulfide. The combination of corrosion and erosion can accelerate the rate of material loss, posing a dual threat to pipeline integrity.

Lastly, temperature fluctuations can exacerbate erosion issues. In colder climates, the freeze-thaw cycles can lead to crack propagation, while in hotter environments, elevated temperatures can weaken the material, making it more susceptible to erosion.

Each of these issues poses a unique set of challenges, but the end result is often the same: reduced pipeline integrity, increased maintenance costs, and heightened risk of catastrophic failure. That’s why effective erosion monitoring, facilitated by the right probe, is not just beneficial but essential for the long-term viability of any oil and gas pipeline.

From a safety perspective, the risks are even more alarming. Erosion-related pipeline failures can lead to leaks or ruptures that pose immediate dangers, such as fires or explosions. These incidents risk not only the lives of the workers on-site but also those in surrounding communities. Additionally, leaks can result in environmental contamination, affecting local ecosystems and water supplies, which has long-term health implications.

Why Erosion Probes are Essential

How Erosion Probes Help in Monitoring and Managing Pipeline Health

Erosion probes serve as the eyes and ears of your pipeline system, offering real-time insights that are critical for effective management. These sophisticated devices are strategically placed at various points along the pipeline, particularly in areas prone to high erosion rates, such as bends, junctions, and varying diameter sections.

Once installed, the probes continuously monitor the flow conditions and wall thickness of the pipeline. They detect even the slightest changes in material loss, allowing for early identification of erosion hotspots. This timely data is invaluable for making informed decisions about when and where to conduct maintenance, thereby preventing minor issues from escalating into major problems.

Moreover, modern erosion probes come equipped with advanced features like remote monitoring and automated alerts. This means you can receive instant notifications about any concerning changes in pipeline conditions, allowing for immediate intervention. Such capabilities not only reduce the need for manual inspections but also enhance the speed and accuracy of your response to potential issues.

The Technology Behind Erosion Probes

Erosion probes are marvels of modern engineering, combining various technologies to provide accurate and reliable monitoring of pipeline health. At their core, these probes typically use ultrasonic or electromagnetic sensors to measure wall thickness and detect material loss in real time. These sensors emit waves that bounce back upon hitting the pipeline wall, and the time it takes for the wave to return helps calculate the wall’s thickness. Any change in this timing indicates erosion or material loss.

In addition to basic sensing technology, many advanced erosion probes also incorporate machine learning algorithms. These algorithms analyze historical and real-time data to predict future erosion patterns, giving operators a more comprehensive understanding of their pipeline’s health. This predictive capability is invaluable for planning maintenance activities and avoiding unexpected failures.

Connectivity is another crucial aspect of erosion probe technology. Most modern probes are equipped with wireless communication modules that enable remote monitoring. This feature allows operators to access real-time data from anywhere, facilitating quicker decision-making and immediate intervention when necessary.

Some of the latest erosion probes even come with self-calibrating features, ensuring that the data collected is always accurate and reliable. This eliminates the need for frequent manual calibrations, saving both time and resources.

In essence, the technology behind erosion probes is a blend of sensing, data analytics, and connectivity, designed to offer a holistic solution for monitoring and managing pipeline erosion. It’s not just about detecting problems; it’s about providing the tools to understand, predict, and ultimately prevent them.

Cost-Benefit Analysis

Cost Factors:

Pemeliharaan: Periodic calibration and servicing to ensure optimal performance.

Software Subscription: If applicable, a yearly subscription fee for cloud-based monitoring and analytics.

Long-Term Benefits: Reduced Maintenance

Costs: By identifying erosion hotspots early, you can target maintenance efforts more effectively, reducing overall costs.

Extended Pipeline Lifespan: Proactive monitoring helps prevent catastrophic failures, thereby extending the useful life of your pipeline system.

Regulatory Compliance: Our probes help you meet industry standards and regulations, potentially saving you from hefty fines and legal complications.

Operational Efficiency: Real-time data and predictive analytics enable smarter decision-making, optimizing your operations.

Keamanan: Early detection of erosion risks can prevent accidents, protecting both human lives and the environment.

ROI: The return on investment is substantial when you consider the cost savings from targeted maintenance, extended pipeline life, and avoided regulatory fines.

The Bottom Line:

While the initial cost of investing in our erosion probes may seem significant, the long-term benefits far outweigh the expenses. Not only do you save on maintenance and extend the life of your pipeline, but you also enhance safety and compliance, all of which contribute to a strong ROI. In essence, our erosion probes are not a cost but an investment in the future of your operations.

Why Erosion Probes are Essential

Erosion probes serve as the eyes and ears of your pipeline system, offering real-time insights that are critical for effective management. These sophisticated devices are strategically placed at various points along the pipeline, particularly in areas prone to high erosion rates, such as bends, junctions, and varying diameter sections.

Once installed, the probes continuously monitor the flow conditions and wall thickness of the pipeline. They detect even the slightest changes in material loss, allowing for early identification of erosion hotspots. This timely data is invaluable for making informed decisions about when and where to conduct maintenance, thereby preventing minor issues from escalating into major problems.

Moreover, modern erosion probes come equipped with advanced features like remote monitoring and automated alerts. This means you can receive instant notifications about any concerning changes in pipeline conditions, allowing for immediate intervention. Such capabilities not only reduce the need for manual inspections but also enhance the speed and accuracy of your response to potential issues.

In summary, erosion probes are indispensable tools for maintaining the health of your oil and gas pipelines. They provide the data you need to manage erosion proactively, optimize maintenance schedules, and ultimately, extend the lifespan of your pipeline infrastructure.

Kesimpulan

In conclusion, our erosion probes are more than just monitoring devices; they are a strategic investment in the future of your oil and gas operations. With cutting-edge technology, real-time data analytics, and remote monitoring capabilities, these probes offer unparalleled accuracy and reliability. They empower you to manage erosion proactively, optimize maintenance schedules, and extend the lifespan of your pipeline infrastructure. The long-term benefits, both in terms of cost savings and operational efficiency, make the investment in our erosion probes a no-brainer.

Ulasan

Belum ada ulasan.