Deskripsi

Di dunia pemeliharaan pipa dan pemantauan korosi, alat pengambilan korosi adalah peralatan yang sangat diperlukan. Baik Anda berurusan dengan jalur pipa untuk minyak, gas, atau cairan industri lainnya, melacak situasi korosi sangat penting untuk menjaga integritas dan keamanan sistem pipa. Artikel ini bertujuan untuk memberikan tinjauan komprehensif tentang alat pengambilan korosi, pentingnya dalam industri, dan bagaimana hal itu berkontribusi pada pemeliharaan pipa yang efisien.

Pentingnya pemantauan korosi

Korosi adalah proses alami yang terjadi ketika logam bereaksi dengan lingkungannya, yang mengarah ke degradasi material. Dalam kasus pipa, ini dapat menyebabkan kebocoran, pecah, atau bahkan kegagalan sistem. Akibatnya, pemantauan dan pengendalian korosi adalah aspek penting dari pemeliharaan pipa, memastikan keamanan dan umur panjang komponen infrastruktur kritis ini.

Salah satu metode umum pemantauan korosi adalah penggunaan kupon korosi. Potongan -potongan logam kecil yang dibuat dengan hati -hati ini dimasukkan ke dalam pipa dan terkena kondisi yang sama dengan pipa itu sendiri. Korosi yang terjadi pada kupon -kupon ini kemudian dapat dianalisis dan digunakan untuk menilai situasi korosi keseluruhan dalam sistem pipa.

Namun, proses pengambilan dan penggantian kupon korosi ini secara tradisional merupakan upaya yang memakan waktu dan mahal, seringkali membutuhkan pipa untuk depresi dan dimatikan. Di sinilah alat pengambilan korosi ikut bermain, menawarkan solusi yang lebih efisien dan hemat biaya untuk operator pipa.

Pengenalan alat pengambilan korosi

Alat pengambilan korosi adalah perangkat khusus yang dirancang untuk menghapus dan memasang kupon korosi dalam sistem pipa tanpa perlu depresi atau shutdown. Alat inovatif ini tidak hanya menghemat waktu dan uang tetapi juga mengurangi risiko bahaya lingkungan dan keselamatan yang terkait dengan penutupan pipa.

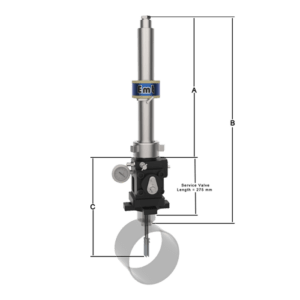

Dibangun dengan komponen stainless steel untuk ketahanan terhadap korosi dan paparan kimia, alat pengambilan korosi beroperasi melalui kontak mekanis, memberikan tindakan yang sensitif dan andal. Alat ini dirancang untuk bekerja dalam berbagai tekanan dan suhu dan dapat digunakan dengan berbagai jenis cairan, menjadikannya solusi serbaguna untuk sistem pipa yang beragam.

Fitur utama dari alat pengambilan korosi

Rentang tekanan: Alat pengambilan korosi dirancang untuk bekerja dengan tekanan hingga 45 MPa, mengakomodasi sebagian besar sistem pipa industri.

Kisaran suhu: Dengan kisaran suhu operasi -20 ° C hingga 100 ° C, alat ini cocok untuk berbagai lingkungan dan jenis cairan.

Kesesuaian: Alat ini dapat digunakan dengan produk minyak bumi, gas alam, dan cairan non-korosif lainnya.

Tinggi pemasangan: Tergantung pada diameter pipa, ketinggian pemasangan peralatan biasanya tidak melebihi 1,5 meter, memastikan kemudahan penggunaan dan aksesibilitas.

Proses pengambilan

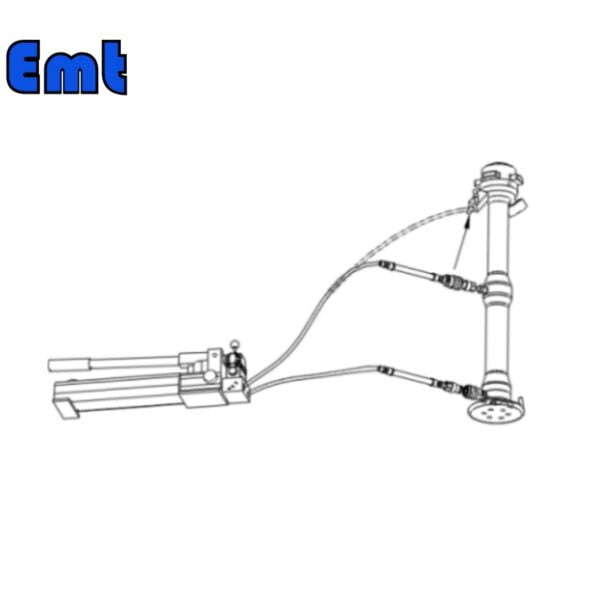

Alat pengambilan korosi menyederhanakan proses pengambilan dan mengganti kupon korosi, menjadikannya solusi yang lebih efisien dan hemat biaya untuk operator pipa. Proses pengambilan umum dapat diringkas dalam langkah -langkah berikut:

Persiapan: Lepaskan penutup pelindung dan steker pipa dari pangkalan, pasang adaptor, dan sambungkan berbagai komponen alat pengambilan.

Pengambilan Kupon Korosi: Menggunakan mekanisme pengangkatan alat, bongkar kupon korosi dan lepaskan dari pipa.

Pemasangan kupon korosi baru: Pasang kupon baru ke mekanisme pengangkatan, masukkan ke dalam pipa, dan kencangkan di tempatnya.

Finalisasi: Tutup berbagai katup, lepaskan alat pengambilan, dan pasang kembali steker pipa dan penutup pelindung.

Pemeliharaan Alat Pengambilan Korosi

Untuk memastikan umur panjang dan kinerja optimal dari alat pengambilan korosi, penting untuk memelihara dan membersihkan peralatan dengan benar setelah setiap penggunaan. Bersihkan semua komponen dan oleskan minyak ke bagian mana pun dengan cincin-O untuk mencegah kerusakan korosi.

Parameter dan fitur utama

Alat pengambilan korosi EMT adalah perangkat berkualitas tinggi, andal, dan efisien yang dirancang untuk penghapusan dan pemasangan kupon korosi dalam berbagai sistem pipa. Alat inovatif ini menawarkan operator pipa solusi yang lebih nyaman dan hemat biaya untuk pemantauan dan pemeliharaan korosi. Di bagian ini, kami akan menguraikan parameter dan fitur utama dari alat pengambilan korosi EMT.

Rentang tekanan: Alat pengambilan korosi EMT dirancang untuk bekerja dengan tekanan hingga 45 MPa (6.525 psi), membuatnya cocok untuk berbagai sistem pipa.

Kisaran suhu: Alat ini mampu beroperasi dalam suhu mulai dari -20 ° C hingga 100 ° C (-4 ° F hingga 212 ° F), memastikan kompatibilitas dengan berbagai lingkungan dan jenis fluida.

Kesesuaian: Alat pengambilan korosi EMT dapat digunakan dengan berbagai jenis cairan, termasuk produk minyak bumi, gas alam, dan cairan non-korosif lainnya.

Kompatibilitas Diameter Pipa: Alat ini cocok untuk digunakan dengan diameter pipa mulai dari 2 inci hingga 48 inci, mengakomodasi spektrum luas ukuran pipa.

Tinggi pemasangan: Dengan tinggi instalasi yang biasanya tidak melebihi 1,5 meter (4,9 kaki), alat pengambilan korosi EMT mudah digunakan dan diakses.

Fitur penting

Konstruksi yang tahan lama: Alat pengambilan korosi EMT dibangun dengan komponen stainless steel berkualitas tinggi, memastikan ketahanan terhadap korosi dan paparan kimia untuk kinerja jangka panjang.

Desain ramah pengguna: Alat ini memiliki desain yang ergonomis, dengan kontrol sederhana dan intuitif yang memungkinkan operasi yang mudah, bahkan dalam kondisi lapangan yang menantang.

Fitur keselamatan: Dilengkapi dengan katup pengaman dan sistem segel yang andal, alat pengambilan korosi EMT meminimalkan risiko kebocoran atau kecelakaan selama proses pengambilan dan pemasangan.

Keserbagunaan: Desain modular alat ini memungkinkan adaptasi yang mudah untuk konfigurasi pipa yang berbeda dan jenis kupon korosi, menjadikannya solusi serbaguna untuk beragam aplikasi.

Pemeliharaan rendah: Alat pengambilan korosi EMT membutuhkan pemeliharaan minimal, memastikan biaya kepemilikan yang rendah dan operasi bebas repot.

Kesimpulan

Alat pengambilan korosi EMT adalah perangkat canggih yang merampingkan proses pengambilan kupon korosi dan pemasangan dalam sistem pipa. Dengan konstruksi yang tahan lama, desain ramah pengguna, dan kemampuan serbaguna, alat ini menawarkan keunggulan signifikan bagi operator pipa dalam hal efisiensi, penghematan biaya, dan keamanan. Alat pengambilan korosi EMT adalah tambahan penting untuk setiap program pemeliharaan pipa, membantu memastikan integritas, keandalan, dan umur panjang aset infrastruktur kritis.

Alat pengambilan korosi adalah inovasi yang mengubah permainan di bidang pemeliharaan pipa dan pemantauan korosi. Dengan memungkinkan pengambilan yang efisien dan penggantian kupon korosi tanpa perlu shutdown pipa atau depresi, alat ini secara drastis mengurangi biaya dan risiko yang terkait dengan metode tradisional. Ketika industri terus berkembang, alat pengambilan korosi tidak diragukan lagi akan memainkan peran penting dalam menjaga keamanan dan integritas sistem pipa di seluruh dunia.

-600x600.jpg)

Ulasan

Belum ada ulasan.