Beschreibung

Einleitung

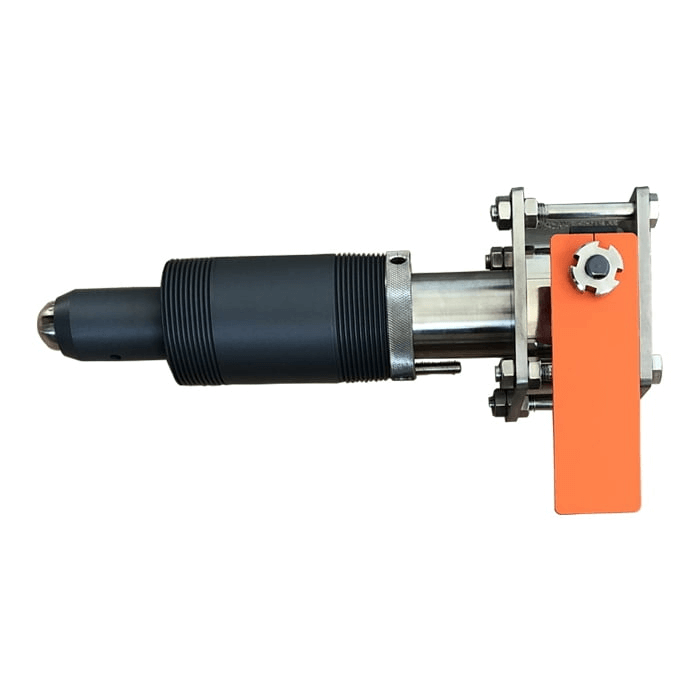

Der intrusive Schweißschweineherde -Signaler ist ein bidirektionales, aufdringliches Gerät, mit dem der Durchgang von Schweinen über eine Pipeline überwacht wird. Es kann mit verschiedenen Arten von Displays ausgestattet werden, darunter A, B, C und D. Das Dichtungsmaterial von SN2-TQZ des intrusiven Schweißschweins Signaller funktioniert mit verschiedenen Flüssigkeiten wie Öl, Erdgas, kaltem Wasser, Meerwasser, Druckluft und Öl. Es ist jedoch nicht für die Verwendung mit bestimmten Medien geeignet, z.

Wenn ein Schwein die Pipeline durchläuft, betätigt der bidirektionale Auslöser jede Anzeige wie folgt:

- A: Es löst eine pop-up-Flagge vom Typ Lock aus.

- B: Das Indikatorflag des Signallers verschiebt sich von einem horizontalen Zustand in einen vertikalen Zustand.

- C: Das Indikatorflag ändert sich erneut von horizontal nach vertikal, und ein elektrischer Schalter (Doppelpole-Doppel-Power) oder Doppelpolel (DPDT) wird aktiviert und aufrechterhalten.

- D: Eine digitale Zeitanzeige beginnt zu zählen und markiert die tatsächliche Zeit, in der der Speicher ausgelöst wird. Der SPDT- oder DPDT-Elektroschalter bleibt aktiv, bis die Werkszeit für die Fabrik erreicht ist. Zu diesem Zeitpunkt kehrt das Display in den Standby-Zustand zurück.

Arbeitsprinzipien des intrusiven Schweißschweinesschilders

Unter Verwendung des SN2-TQZ als Beispiel lautet das Arbeitsprinzip eines intrusiven Schweißschweinessignals wie folgt: Das Gerät verfügt über einen bidirektionalen Trigger -Stürmer, der am Ende einer Bewegung auf der Basis montiert ist. Dieser Stürmer erstreckt sich in den Innenraum des Rohrs in der Nähe der Rohrwand. Wenn ein Schwein durch das Rohr fährt, zieht es den Stürmer, der sich wiederum an einer Stangenstange zieht. Diese Aktion führt dazu, dass eine Flaggenkappe auftaucht. Sobald die Flaggenkappe aufgetaucht ist, bleibt sie in diesem ausgeworfenen Zustand bis man sich manuell zurücksetzen, was auf den Durchgang des Schweins hinweist. Nachdem das Schwein vergangen ist, kehrt der Stürmer automatisch in seine ursprüngliche Position zurück. Zu diesem Zeitpunkt können Sie die Flag -Kappe zwangsläufig drücken, um sie zurückzusetzen und das Gerät wieder in den Standby -Modus zu setzen. If pressing the flag cap does not reset it, this suggests that the pig is still present and the striker has not returned to its original position.

Wichtigste technische Indikatoren

1. Working pressure: 0~5 MPa and 0~16 MPa (or designed according to user needs);

2. Operating Temperature: -20 ~ 120 °C (complete value, which may differ depending on the medium)

3. Base material: Q235A or 20 # (standard configuration)

4. Media compatibility: see overview

Installationsmethode of Welding Pig Signaller

- Installation Guide

- Vorbereitung: Depending on the specific model of the device and the thickness of your pipe, drill a hole in the pipe. For the SN2-TQZ model, which is larger than 114 in diameter, drill a hole of 51mm for pipes 4–15mm thick and 56mm for pipes 16–25mm thick.

- Installation und Test:A. Einstellen der Länge des Stürmers: Der Stürmer ist Teil des Geräts, das in das Rohr greifen muss. Sie können seine Länge einstellen, indem Sie einen Teil des Geräts, der als „Bewegung“ bezeichnet wird, drehen. Nachdem Sie das Gerät installiert haben, sollte der Stürmer leicht über der Innenwand des Rohrs liegen. Zwischen der Oberseite des Geräts und der Oberseite der Basis sollte es einen bestimmten Abstand (mit „B“) geben.B. Schweißen und Installation: Dieser Prozess hat vier Schritte:

- Schritt 1: Legen Sie das Gerät in das Loch, das Sie in das Rohr gebohrt haben. Stellen Sie sicher, dass es mit der Richtung des Rohrs entspricht. Schweißen Sie einen kleinen Punkt, um es an Ort und Stelle zu halten. Wenn das Gerät nicht perfekt passt, müssen Sie es möglicherweise manuell halten.

- Schritt 2: Entfernen Sie den Bewegungsteil von der Basis und halten Sie es in einer sauberen Schachtel.

- Schritt 3: Schweißen Sie die Basis des Geräts auf das Rohr nach Standardschweißverfahren.

- Schritt 4: Sobald es abkühlt ist, tragen Sie etwas Öl auf die Dichtfläche des Geräts und der Basis auf. Legen Sie das Gerät wieder auf die Basis. Stellen Sie sicher, dass die Entfernung „B“ der gleiche ist wie zuvor und dass das Gerät noch mit dem Rohr übereinstimmt. Ziehen Sie einen Teil namens „Sperrenmutter“ an, um das Gerät zu versiegeln und zu verhindern, dass es sich dreht.

Geben Sie eine Empfindlichkeitsinspektion und -anpassung ein

Der Schweißschweinehörer verwendet einen Edelstahlzylinder, der abnehmbar und an der Dichthülle installiert ist. Der Zylinder dient zum Schutz und zur Begrenzung der Indikatorflagge. Nach dem Installieren des Schweißschweinehörers möchten Sie möglicherweise die Empfindlichkeit und Zuverlässigkeit überprüfen. Dazu können Sie die Abwärtsbewegung der Verbindungsstange simulieren, indem Sie den Edelstahlzylinder entfernen. Wenn Sie den Zylinder abschrauben, wird die Flaggenkappe angezeigt.

Das Gerät ist so konzipiert, dass die maximale Verschiebung, die durch die Verbindungsstange erzeugt wird (wenn sich der Stürmer bewegt, um eine 90-Grad-Ablenkung zu erzeugen), 13 mm. Diese Verschiebung entspricht der Entfernung, die der Edelstahlzylinder ausgeht, wenn sich die Flagkkappe auftaucht.

Sie können die Empfindlichkeit des Kugelindikators verbessern, indem Sie den Edelstahlzylinder gegen den Uhrzeigersinn drehen. Achten Sie jedoch darauf, die Empfindlichkeit nicht zu dem Punkt zu erhöhen, an dem die Verschiebung der Verbindungsstange kleiner oder gleich 3 mm ist. Wenn Sie den Zylinder zweimal zweimal drehen, wird die Flaggenkappe angezeigt.

Stellen Sie sicher, dass die Flaggenkappe nicht auf dem Edelstahlzylinder gefroren ist, bevor die Kugelanzeige bei Temperaturen unter dem Gefrierpunkt verwendet wird. Sie können dies überprüfen, indem Sie den Edelstahlzylinder gegen den Uhrzeigersinn drehen. Wenn die Flaggenkappe auftaucht, funktioniert das Gerät einwandfrei. Wenn es nicht auftaucht, kann die Flaggenkappe stecken bleiben. In diesem Fall sollten Sie sie trennen, die Kontaktfläche zwischen den beiden trocknen und sie in ihre ursprüngliche Position zusammenbauen.

Unser Service

Unser Engagement

Customer satisfaction is our top priority at our organization. We’re proud to offer a diverse selection of welding pig signallers, designed to cater to a wide range of specific needs. Feel free to connect with us to discover the solution that best aligns with your requirements.

Qualitätssicherung

To demonstrate the superior quality of our offerings, we give clients the opportunity to request sample units. We believe in the excellence of our products and want you to experience it firsthand.

Customer Service

Unsere Vorgänge drehen sich darum, einen hervorragenden Kundenservice zu bieten. Unser Team ist bereit, sofortige Antworten zu liefern und Ihre Fragen oder Bedenken zu beantworten. Wir sind hier, um Ihnen so schnell wie möglich zu helfen.

Lieferung und Verpackung

Wir verstehen die Bedeutung der rechtzeitigen Lieferung. Deshalb bemühen wir uns, Ihre Bestellungen so schnell wie möglich zu erfüllen. Unser Online -Support ist immer im Dienst, rund um die Uhr und sicherzustellen, dass Ihre Bedürfnisse zu jeder Tages- oder Woche erfüllt werden.

Unsere Produkte sind in Fällen bequem verpackt, um eine Vielzahl von Vorteilen zu erhalten, darunter:

- Die Fälle sind leicht und doch stark, mit klaren Linien und einer Isolierung. Sie behalten ihre Form ohne Verformung auf.

- Die Verwendung von Fällen beseitigt die Notwendigkeit einer Begasung, was zu einem optimierten Versandprozess führt.

In allem, was wir tun, sind wir bestrebt, erstklassige chemische Injektionsquills effizient zu liefern, wobei wir uns unerschütterlich auf die Kundenzufriedenheit konzentrieren.

Rezensionen

Es gibt noch keine Bewertungen.