Beschreibung

I. Einleitung

Rohrreinigungsreiniger aus Fluorkautschuk sind leistungsstarke, kostengünstige und belastbare Werkzeuge, die insbesondere in anspruchsvollen Industrieumgebungen einen wertvollen Beitrag zur Aufrechterhaltung der Rohrgesundheit und -effizienz leisten.

Rohrreinigungsreiniger aus Fluorkautschuk sorgen für einen kontinuierlichen und optimalen Rohrbetrieb. Entfernen Sie angesammelten Schmutz und Rost, um Reibung und Druck im Rohr zu minimieren, das Risiko von Lecks oder Brüchen zu verringern und die Lebensdauer des Rohrs zu verlängern. Es verbessert auch die Qualität des transportierten Materials, sei es Öl, Gas, Wasser oder andere Materialien.

II. Bedeutung der Pipeline-Reinigung

Die Rohrreinigung ist eine vorbeugende Wartungsmaßnahme zur Wartung von Rohrsystemen und eine wichtige Routineaufgabe in Branchen, die auf den Transport von Rohren angewiesen sind.

Die Rohrreinigung ist ein entscheidender Aspekt für die Aufrechterhaltung der Effizienz, Sicherheit und Langlebigkeit von Rohrsystemen. Im Laufe der Zeit können sich in Rohren Ablagerungen, Sedimente, Rost und andere unerwünschte Materialien ansammeln, die den Materialfluss in den Rohren behindern können. Wenn diese Hindernisse nicht bekämpft werden, können sie die Betriebseffizienz verringern, den Verschleiß an Rohrleitungen erhöhen und möglicherweise ernsthafte Sicherheitsrisiken mit sich bringen. Daher ist Rohrmolch eine gute Wahl, um diese Rohrprobleme zu lösen. Fluorkautschuk-Rohrreinigungsschweine sind eine Art Rohrreinigungsschweine.

III. Arten von Pipeline-Molchen

Wir bieten eine große Auswahl an Pfeifenreinigern. Es gibt vier Arten von Rohrmolchen: Schaummolch, Knochenmolch, ABS-Molch, Gummimolch.

Schaumschweine: Diese sind leicht, flexibel, vielseitig und aus Polyurethanschaum gefertigt. Sie werden häufig für Trocknungs-, Reinigungs- und Verdrängungsaufgaben innerhalb von Rohren eingesetzt.

Dürre Schweine: Dürre Schweine bestehen aus einem stabilen Rahmen und sind häufig mit einer Drahtbürste ausgestattet. Sie sind für aggressivere Reinigungsaufgaben konzipiert. Sie eignen sich hervorragend zum Entfernen von verhärteten Ablagerungen und Rost.

ABS-Molch: Diese aus Acrylnitril-Butadien-Styrol (ABS) hergestellten Molche sind für ihre Festigkeit und Haltbarkeit bekannt und werden häufig für anspruchsvolle Reinigungs- und Verdrängungsaufgaben eingesetzt.

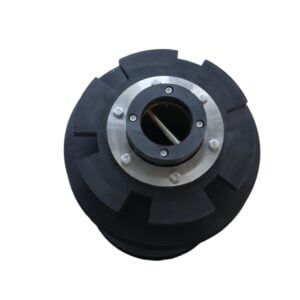

Gummischwein: Es besteht hauptsächlich aus Gummi und ist vielfältig einsetzbar und flexibel, um Rohre effektiv zu reinigen und gleichzeitig Drehungen und Durchmesseränderungen gut zu kontrollieren. Rohrreinigungsreiniger aus Fluorkautschuk sind leistungsstarke, kostengünstige und belastbare Werkzeuge, die insbesondere in anspruchsvollen Industrieumgebungen einen wertvollen Beitrag zur Aufrechterhaltung der Rohrgesundheit und -effizienz leisten.

IV. Das Material: Fluorkautschuk

Fluorelastomer, auch Fluorelastomer genannt, ist ein synthetischer Gummi, der für seine hervorragende Hitzebeständigkeit, chemische Beständigkeit und Ölbeständigkeit bekannt ist. Dadurch eignen sich Fluorkautschuk-Rohrreinigungsreiniger besonders für die Rohrreinigung in Branchen, in denen diese Bedingungen vorherrschen, beispielsweise in der Öl- und Gasindustrie.

Hinsichtlich des Designs sind Fluorkautschuk-Rohrreinigungsreiniger sorgfältig darauf ausgelegt, dass sie sich selbst bei Biegungen, Durchmesserschwankungen und anderen schwierigen Rohrkonfigurationen nahtlos durch das Rohr bewegen. Es kann Schmutz, Rost und andere unerwünschte Materialien effektiv von Rohrwänden entfernen, ohne Schäden oder unnötigen Verschleiß zu verursachen.

Darüber hinaus sind Rohrreiniger aus Fluorkautschuk nicht nur effizient, sondern auch langlebig. Die Elastizität des Fluorkautschuks sorgt dafür, dass der Molch über einen langen Zeitraum wiederverwendet werden kann und stellt somit eine wirtschaftliche Lösung für die regelmäßige Wartung der Rohrleitung dar.

V. Bau eines Rohrreinigungsmolchs aus Fluorkautschuk

- A. Detaillierte Analyse der verschiedenen Komponenten des Fluorkautschuk-Rohrreinigungsmolchs: Der Fluorkautschuk-Rohrreinigungsmolch besteht hauptsächlich aus einem starken Körper aus Fluorkautschuk, der normalerweise mit einem versiegelten Becher oder einer versiegelten Scheibe ausgestattet ist, um die Reinigungseffizienz zu verbessern. Für aggressivere Reinigungsaufgaben kann er auch mit einem Bürsten- oder Schabermechanismus ausgestattet sein.

- B. Rolle und Bedeutung der Komponenten: Der Körper aus Fluorkautschuk verleiht dem Molch Flexibilität und Haltbarkeit, sodass er durch die Rohrleitung navigieren und rauen Bedingungen standhalten kann. Dichtungsbecher oder -scheiben sorgen für eine dichte Abdichtung im Rohr und stellen sicher, dass keine Rückstände zurückbleiben. Falls vorhanden, hilft ein Bürsten- oder Schabermechanismus dabei, hartnäckige Ablagerungen oder Rost von den Rohrwänden zu entfernen.

VI. Wie Fluorkautschuk-Pipeline-Reinigungsmolche funktionieren

- A. Detaillierte Erläuterung des Betriebsablaufs

Der Rohrreinigungsmolch aus Fluorkautschuk wird in den Molchwerfer eingeführt, der Teil des Rohrs ist, mit dem der Molch in das Rohr eingeführt wird. Der Druck des Flüssigkeitsstroms im Rohr drückt dann den Molch entlang des Rohrs und ermöglicht ihm so die Reinigung der Innenfläche.

- B. Die Wissenschaft hinter dem Reinigungsprozess

Während sich der Fluorkautschuk-Rohrreinigungsmolch durch das Rohr bewegt, biegt sich sein Fluorkautschukkörper, um sich dem Durchmesser des Rohrs anzupassen, wodurch eine dichte Abdichtung entsteht. Zusammen mit einer Bürste oder einem Schaber entfernt diese Dichtung wirksam Schmutz, Ablagerungen und Rost von den Rohrwänden und hinterlässt eine saubere Oberfläche.

VII. Vorteile der Verwendung von Rohrreinigungsmolchen aus Fluorkautschuk

- A. Hohe Effizienz der Rohrleitungsreinigung: Die Kernfunktion von Fluorkautschuk-Pipeline-Reinigungsmolchen ist die Reinigung. Entfernen Sie effektiv Schmutz, Sedimente und Rost an der Rohrwand, sorgen Sie für einen reibungslosen Materialfluss und verbessern Sie die Arbeitseffizienz erheblich.

- B. Haltbarkeit und Langlebigkeit von Fluorkautschukmolchen: Diese Molche bestehen aus Fluorkautschuk, einem Material, das für seine Elastizität und Widerstandsfähigkeit gegenüber rauen Bedingungen bekannt ist, und diese Molche sind äußerst langlebig. Sie halten einer wiederholten Verwendung über lange Zeiträume stand und sind daher ein zuverlässiges Werkzeug für die regelmäßige Wartung von Rohrleitungen.

- C. Kosteneffizienz und Einsparungen: Die Kombination aus Effizienz und Haltbarkeit macht Rohrreinigungsreiniger aus Fluorkautschuk zu einer kostengünstigen Lösung für die Rohrreinigung. Ihre lange Lebensdauer reduziert die Notwendigkeit eines häufigen Austauschs, was auf lange Sicht zu erheblichen Kosteneinsparungen führt. Darüber hinaus minimiert ihre hohe Reinigungseffizienz potenzielle Reparaturkosten für Rohrleitungen aufgrund unbeaufsichtigter Verstopfungen oder Korrosion.

VIII. Industrieanwendungen von Fluorkautschuk-Pipeline-Reinigungsmolchen

- A. Öl- und Gasindustrie: In der Öl- und Gasindustrie sind Fluorkautschuk-Rohrreinigungsreiniger von unschätzbarem Wert für die Aufrechterhaltung der Effizienz und Sicherheit von Pipelines. Sie können Sedimente und andere Hindernisse, die den Öl- und Gasfluss behindern, effektiv entfernen.

- B. Wasseraufbereitungsindustrie: In Wasseraufbereitungsanlagen spielen diese Schweine eine entscheidende Rolle bei der Gewährleistung der Sauberkeit von Wasserleitungen und der Verhinderung der Bildung von Mineralablagerungen, Biofilmen und anderen potenziellen Verunreinigungen.

- C. Andere erwähnenswerte Branchen: Darüber hinaus können Fluorkautschuk-Rohrreiniger auch in Branchen wie der Lebensmittel- und Getränkeindustrie eingesetzt werden, in denen Rohrhygiene von größter Bedeutung ist, und in der chemischen Industrie, wo die chemische Beständigkeit von Rohrreinigern sehr vorteilhaft ist.

IX. Wartung und Pflege von Rohrreinigungsmolchen aus Fluorkautschuk

- Regelmäßige Wartung: Überprüfen Sie regelmäßig den Verschleiß des Fluorkautschuk-Rohrreinigungsrohrs und reinigen Sie es nach jedem Gebrauch, um eine optimale Leistung zu gewährleisten. Außerdem ist es wichtig, sie an einem trockenen und kühlen Ort zu lagern, um das Fluorkautschukmaterial vor Zersetzung zu schützen.

- B. Häufige Probleme und ihre Lösungen: Im Laufe der Zeit können Fluorkautschuk-Rohrreiniger ihre Flexibilität verlieren oder Anzeichen von Schäden aufweisen. In diesem Fall empfiehlt es sich, den Molch auszutauschen, um die Wirksamkeit der Rohrreinigung aufrechtzuerhalten. Bei bestimmten Rohr- und Reinigungsaufgaben kann die Verwendung der richtigen Molchgröße und des richtigen Molchtyps dazu beitragen, viele häufige Probleme zu vermeiden.

X. Fazit

Kurzum: Fluorkautschuk-Rohrreinigungsreiniger sind in vielen Branchen unverzichtbare Hilfsmittel und leisten einen wesentlichen Beitrag zur Wartung und Lebensdauer von Rohrsystemen. Ihre Konstruktion und Materialien ermöglichen eine effektive und effiziente Reinigung, während ihre Langlebigkeit eine kostengünstige Lösung für die regelmäßige Rohrwartung darstellt. Regelmäßige Pflege und Wartung dieser Schweine sorgt für optimale Leistung und Langlebigkeit. Ob in der Öl- und Gasindustrie, der Wasseraufbereitung, der Lebensmittel- und Getränkeindustrie oder der chemischen Industrie – diese Werkzeuge spielen eine entscheidende Rolle für den reibungslosen und sicheren Betrieb von Pipelines.

-1024x739.jpg)

-300x300.jpg)

Rezensionen

Es gibt noch keine Bewertungen.