Beschreibung

Einleitung

Im industriellen Bereich sind Schnellverschlüsse unverzichtbare Komponenten, die einen schnellen und sicheren Zugang zum Inneren von Druckbehältern, Rohrleitungen und ähnlichen Systemen ermöglichen. Diese mechanischen Geräte können schnell geöffnet und geschlossen werden, was eine einfache Inspektion, Wartung und Reinigung ermöglicht und gleichzeitig eine sichere Abdichtung gewährleistet.

Ihre Bedeutung ist in verschiedenen Sektoren wie der Öl- und Gasindustrie, der Petrochemie und der Pharmaindustrie immens. Durch die Ermöglichung eines schnellen Zugriffs für Betriebsaufgaben, routinemäßige Wartungsarbeiten und Notfalleinsätze optimieren Schnellverschlüsse Betriebsabläufe, reduzieren Ausfallzeiten und halten hohe Sicherheitsstandards aufrecht.

Schnelle Schließungen verstehen

Im Kern handelt es sich bei einem Schnellverschluss um eine mechanische Vorrichtung, die für eine sichere Abdichtung einer Rohrleitung oder eines Druckbehälters sorgt und gleichzeitig bei Bedarf einen schnellen und einfachen Zugang ermöglicht. Sie werden typischerweise in Industriebetrieben eingesetzt, wo häufige Inspektionen, Wartungen oder Reinigungen erforderlich sind und Ausfallzeiten minimiert werden müssen.

Schnellverschlüsse erzeugen eine Dichtung, die den Druck- und Temperaturbedingungen innerhalb der Rohrleitung oder des Behälters standhält. Trotz ihrer komplexen Funktion sind die Kernkomponenten von Schnellverschlüssen relativ einfach.

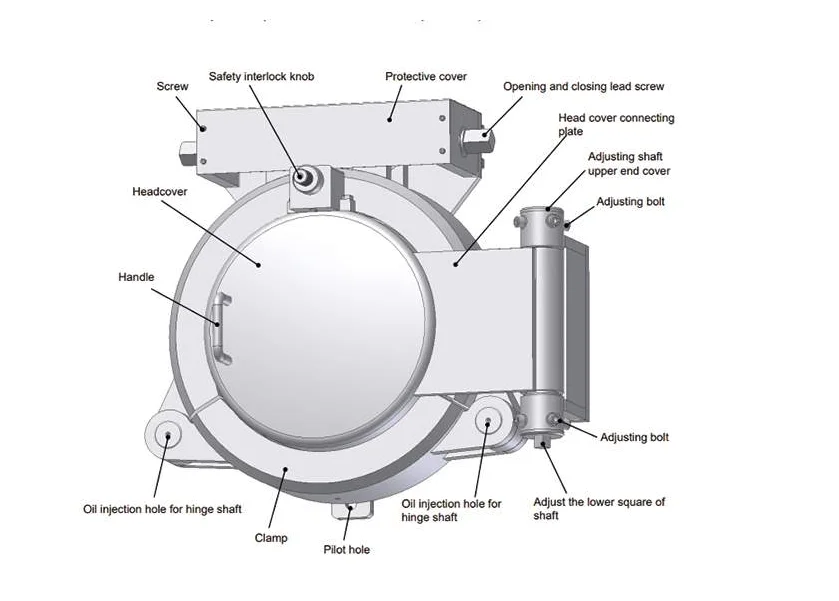

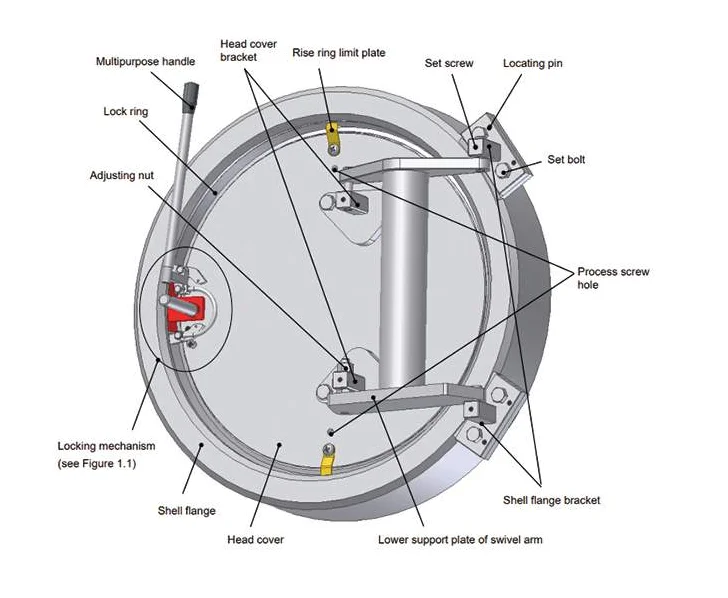

Zu den Schlüsselkomponenten eines Schnellverschlusses gehören typischerweise die Tür, die Dichtung und der Betätigungsmechanismus. Die Tür ist die Hauptkomponente, die sich öffnet und schließt und den Zugang zum Inneren des Behälters oder der Rohrleitung ermöglicht. Die Dichtung, meist aus einem flexiblen Material, sorgt für einen dichten Verschluss, der den inneren Bedingungen des Systems standhält. Der Betätigungsmechanismus, der je nach Art des Schnellverschlusses erheblich variieren kann, ermöglicht das schnelle Öffnen und Schließen der Tür.

Im Betrieb wird die Tür des Schnellverschlusses durch Betätigung des Betätigungsmechanismus geöffnet. Dies kann häufig manuell und ohne Werkzeug erfolgen. Nach dem Öffnen ist der Zugang zum Inneren der Rohrleitung oder des Behälters zur Inspektion, Wartung oder Reinigung möglich. Nach Abschluss dieser Aufgaben wird die Tür geschlossen und die Dichtung eingerastet, wodurch ein sicherer Verschluss entsteht, der den Betriebsbedingungen des Systems standhält.

Arten von Schnellverschlüssen

Schnellverschlüsse gibt es in verschiedenen Ausführungen, jeder mit seinem einzigartigen Design und Betriebsmechanismus. Zu den drei gebräuchlichsten gehören der Bajonetttyp, der Klemmtyp und der Sicherungsringtyp. Diese Typen erfüllen unterschiedliche betriebliche Anforderungen und Pipeline-Konfigurationen und bieten jeweils ihre einzigartigen Vorteile.

Der Bajonett-Schnellverschluss verwendet einen Mechanismus mit männlichem/weiblichem Teil, der ein schnelles Öffnen und Schließen ermöglicht. Der Klemmtyp verwendet einen klappbaren Klemmmechanismus, der eine sichere Abdichtung bietet und gleichzeitig einfach zu bedienen ist. Schließlich verfügt der Lock-Ring-Typ über einen Sicherungsring, der die Tür sicher an Ort und Stelle hält und zum Öffnen schnell gelöst werden kann. Das Verständnis der Nuancen dieser Typen kann bei der Auswahl des am besten geeigneten Schnellverschlusses für bestimmte industrielle Anwendungen hilfreich sein.

Technische Indikatoren für Schnellverschlüsse

- Nenndurchmesser (DN): Dies bezieht sich auf den Standarddurchmesser der Rohrleitung oder des Druckbehälters. Dies ist ein entscheidender Faktor bei der Bestimmung der Größe des benötigten Schnellverschlusses.

- Auslegungsdruck (PN): Dies stellt den maximalen Druck dar, für den das System ausgelegt ist. Der Schnellverschluss muss diesem Druck standhalten, um Sicherheit und Integrität zu gewährleisten.

- Arbeitsmedium: Dies ist der Stoff (Gas, Flüssigkeit usw.), der durch die Rohrleitung fließt oder im Druckbehälter enthalten ist. Das Material des Schnellverschlusses sollte mit diesem Medium kompatibel sein, um Korrosion oder Schäden zu verhindern.

- Auslegungstemperatur: Dies ist die maximale Temperatur, für die das System ausgelegt ist. Der Schnellverschluss muss dieser Temperatur standhalten, ohne seine Funktionalität oder Sicherheit einzubüßen.

- Material: Das Material des Schnellverschlusses sollte robust genug sein, um dem Arbeitsmedium, der Auslegungstemperatur und dem Auslegungsdruck standzuhalten. Bei Bedarf sollte es auch Korrosionsbeständigkeit bieten.

- Rohrdicke: Die Dicke der Rohrwand bestimmt die Robustheit der Rohrleitung oder des Druckbehälters. Der Schnellverschluss muss mit dieser Dicke kompatibel sein, um eine ordnungsgemäße Passform und Abdichtung zu gewährleisten.

Anwendungen von Schnellverschlüssen

Schnellverschlüsse werden in verschiedenen Branchen umfassend eingesetzt, wobei jede Anwendung einzigartig und auf die spezifischen Anforderungen dieser Branche zugeschnitten ist.

Im Öl- und GasindustrieSchnellverschlüsse werden häufig in Rohrleitungen und Druckbehältern eingesetzt, die für den Transport und die Lagerung von Erdölprodukten verwendet werden. Sie ermöglichen eine regelmäßige Inspektion und Wartung, was in dieser Branche von entscheidender Bedeutung ist, um Lecks zu verhindern und den sicheren Umgang mit diesen flüchtigen Substanzen zu gewährleisten. Beispielsweise könnte ein Schnellverschluss an der Zugangsöffnung eines Rohöllagertanks verwendet werden, um eine einfache Inspektion und Reinigung zu ermöglichen.

Der Petrochemische Industrie Darüber hinaus werden Schnellverschlüsse in großem Umfang in ähnlichen Anwendungen wie in der Öl- und Gasindustrie eingesetzt. Sie werden in chemischen Reaktoren, Separatoren und Filtern eingesetzt, wo für Reinigung, Wartung oder Inspektion ein schneller Zugang erforderlich ist. Beispielsweise könnte ein Schnellverschluss an einem Chemiereaktorbehälter installiert werden, der die regelmäßige Inspektion und Wartung der internen Komponenten erleichtert.

Im Pharmaindustrie, Schnellverschlüsse werden in sterilen Umgebungen verwendet, in denen ein schneller und sauberer Zugang erforderlich ist, beispielsweise in Bioreaktoren oder Fermentern. Sie stellen sicher, dass die Integrität des Systems gewahrt bleibt und ermöglichen bei Bedarf dennoch einen einfachen Zugriff.

Der Wasserbehandlungsbranche verwendet Schnellverschlüsse an Filtereinheiten oder Druckbehältern. Sie ermöglichen einen schnellen und einfachen Austausch von Filtermedien oder internen Komponenten, ohne dass umfangreiche Ausfallzeiten erforderlich sind.

Diese Beispiele geben einen Überblick über die Vielseitigkeit und Bedeutung von Schnellverschlüssen in verschiedenen Branchen. Ihre Fähigkeit, einen sicheren und schnellen Zugriff zu ermöglichen, macht sie zu einem unschätzbar wertvollen Werkzeug für eine Vielzahl von Anwendungen.

Wartungs- und Sicherheitsüberlegungen

Die richtige Wartung ist entscheidend für die Langlebigkeit und den sicheren Betrieb von Schnellverschlüssen. Regelmäßige Inspektionen können die effektive und sichere Funktion des Schnellverschlusses gewährleisten und gleichzeitig unerwartete Ausfälle und kostspielige Reparaturen verhindern.

Bei der routinemäßigen Wartung von Schnellverschlüssen werden in der Regel die Dichtungen überprüft und bei Bedarf ausgetauscht, da eine abgenutzte oder beschädigte Dichtung die Integrität des Verschlusses beeinträchtigen kann. Um einen reibungslosen Betrieb zu gewährleisten, sollte der Betätigungsmechanismus regelmäßig auf Anzeichen von Verschleiß oder Beschädigung überprüft und geschmiert werden. Auch die Tür und andere Bauteile sollten auf Anzeichen von Korrosion oder Beschädigung überprüft werden.

Beim Umgang mit Schnellverschlüssen steht die Sicherheit an erster Stelle, insbesondere weil diese häufig bei Hochdrucksystemen zum Einsatz kommen. Beim Öffnen eines Schnellverschlusses muss unbedingt sichergestellt werden, dass das System vollständig drucklos ist, um einen plötzlichen Druckabfall zu verhindern. Bei Wartungs- oder Inspektionsarbeiten sollte geeignete Schutzausrüstung wie Handschuhe und Schutzbrille getragen werden.

Darüber hinaus sollten alle Verfahren im Zusammenhang mit Betrieb, Wartung und Sicherheit von Schnellverschlüssen klar dokumentiert und strikt befolgt werden. Darüber hinaus sollte das gesamte Personal, das Schnellverschlüsse bedient oder wartet, regelmäßig geschult werden.

Schlussfolgerung

Schnellverschlüsse haben sich in einer Vielzahl von Branchen zu einem unverzichtbaren Werkzeug entwickelt, unter anderem in den Bereichen Öl und Gas, Petrochemie, Pharmazie und Wasseraufbereitung. Ihr einzigartiges Design erleichtert den schnellen Zugang zu Druckbehältern und Rohrleitungen und ermöglicht so eine einfache Inspektion, Wartung und Reinigung bei gleichzeitiger Gewährleistung von Sicherheit und Betriebsintegrität.

Ihre Anpassungsfähigkeit und Praktikabilität machen sie für verschiedene Anwendungen von unschätzbarem Wert. Von der Erleichterung der regelmäßigen Wartung in der Öl- und Gasindustrie bis hin zur Gewährleistung des sterilen Zugangs in der Pharmaindustrie haben Schnellverschlüsse ihre Vielseitigkeit immer wieder unter Beweis gestellt. Ihr Design, sei es in Bajonett-, Klemm- oder Sicherungsringausführung, deckt unterschiedliche Betriebsanforderungen und Systemkonfigurationen ab und steigert ihren Nutzen zusätzlich.

Das Verständnis der Nuancen von Schnellverschlüssen – von ihren Kernkomponenten und der Funktionsweise bis hin zu den technischen Indikatoren, die ihre Auswahl leiten – ist entscheidend für die Maximierung ihrer Vorteile. Das richtige Wissen kann bei der Auswahl des richtigen Schnellverschlusses für eine bestimmte Anwendung hilfreich sein und optimale Leistung, Sicherheit und Haltbarkeit gewährleisten.

Rezensionen

Es gibt noch keine Bewertungen.