Beschreibung

I. Einleitung

A. Definition von EMT Schnellverschluss

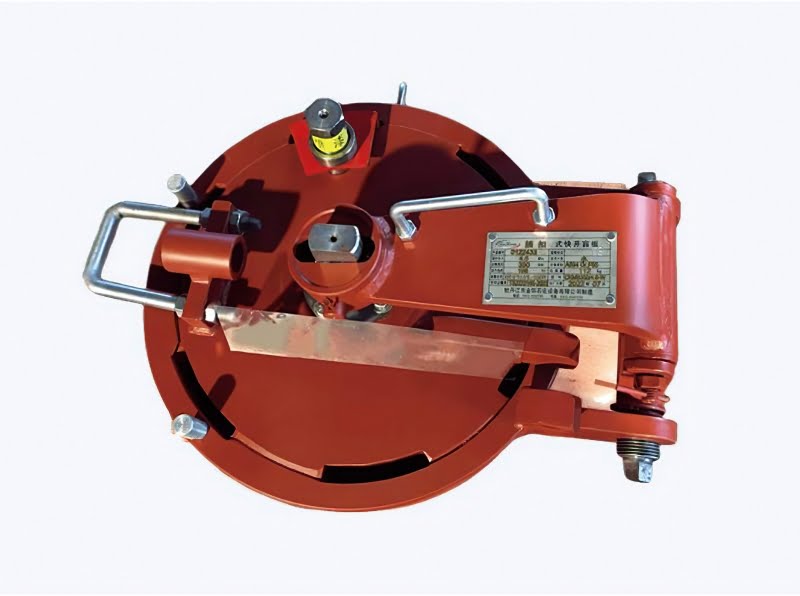

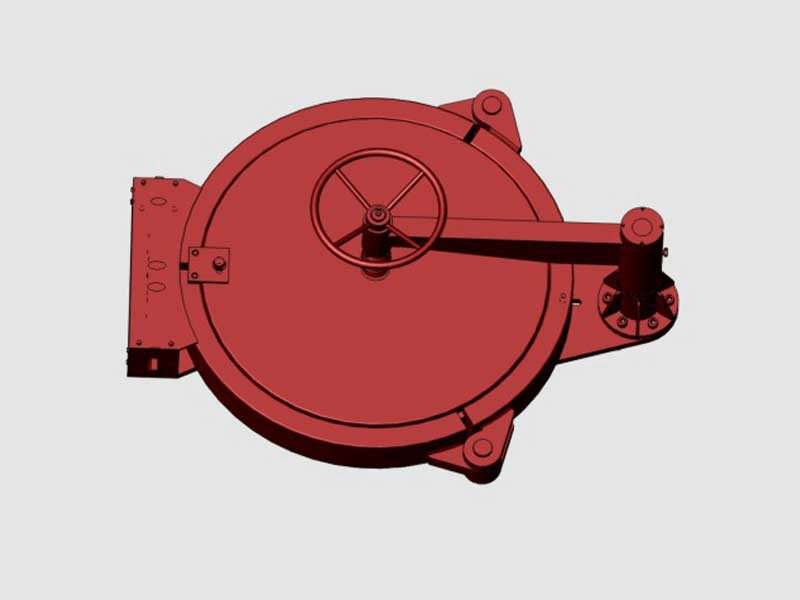

Ein Schnellverschluss (QOC) ist ein innovativer Mechanismus, der speziell für Druckbehälter entwickelt wurde, die den schnellen und sicheren Zugang zu ihrem Innenraum erleichtert. Dieses Verschlusssystem ist so konzipiert, dass sie hohem Druck standhalten und die Sicherheit und Effizienz des Betriebs sicherstellen.

B. Zweck von EMT QOC

Das Hauptziel eines QOC ist es, die Zeit und den Aufwand für das Öffnen und Schließen eines Druckbehälters erheblich zu verkürzen. Diese Funktion ist in Branchen von entscheidender Bedeutung, in denen die operative Effizienz und Sicherheit von größter Bedeutung sind.

Ii. Design und Konstruktion

A. Komponenten von EMT QOC

Das QOC besteht aus mehreren kritischen Komponenten wie der Hub-, Deck-, Verriegelungssystem- und Versiegelungsdichtung. Jedes Element spielt eine wesentliche Rolle bei der Gewährleistung einer robusten und luftdichten Schließung, die zur allgemeinen Sicherheit und Effizienz des Systems beiträgt.

B. Typische Anwendungen von EMT QOC

QOCs werden in zahlreichen Branchen in einer Reihe von Druckgefäßen häufig verwendet. Sie sind in Sektoren wie Öl und Gas, chemischer Verarbeitung und Stromerzeugung besonders weit verbreitet, wo sie zur betrieblichen Effizienz und Sicherheit beitragen.

C. Vorteile

Die Hauptvorteile von EMT -QOC umfassen verkürzte Betriebszeit, erhöhte Sicherheit und verbesserte Betriebseffizienz. Durch die Vereinfachung des Öffnungs- und Schließens der Druckbehälter tragen EMT -QOCs erheblich zur Produktivität des industriellen Betriebs bei.

Erhöhte Sicherheit: Einer der wichtigsten Vorteile von EMT -QOCs ist die verbesserte Sicherheit, die sie bieten. Ihr robustes Design und Sichere Verriegelungsmechanismen minimieren das Risiko von Zufällige Öffnungsogar unter extremem Druck. Dies macht sie zu einem unschätzbaren Werkzeug bei der Aufrechterhaltung sichere Operationeninsbesondere in Branchen, in denen Druckbehälter einem hohen internen Druck ausgesetzt sind. Darüber hinaus kann die Verwendung von EMT -QOCs dazu beitragen, die Inzidenz von Verletzungen am Arbeitsplatz im Zusammenhang mit dem Umgang mit Druckbehältern zu verringern, die zu einem beitragen Sicherer Arbeitsumgebung.

Kosten und Zeiteffizienz: Zusätzlich zu Betriebseffizienz, EMT QOCs bieten auch erhebliche Kosten- und Zeiteinsparungen. Durch die Reduzierung der Zeit, die zum Öffnen und Schließen von Druckgefäßen erforderlich ist, können EMT -QOCs dazu beitragen, Ausfallzeiten zu minimieren und so die Produktivität zu erhöhen. Darüber hinaus verringert ihr robustes und langlebiges Design die Notwendigkeit häufiger Ersatz, was zu niedrigeren Wartungskosten führt. Dies macht in Kombination mit dem Potenzial zur Vorbeugung von Unfällen und den damit verbundenen Kosten EMT-QOCs zu einer kostengünstigen Lösung für Branchen, die auf die Verwendung von Druckbehältern beruhen.

D. Einhaltung Internationale Standards

QOCs are designed and manufactured to comply with stringent international standards, including ASME VIII div. 1 & 2 and ISO EN 13445. This compliance ensures the quality, safety, and reliability of the QOC systems.

E. Überprüfung durch Finite Element Analyse (FEA)

Die strukturelle Integrität und Leistung von QOC -Designs werden durch Finite -Elemente -Analyse (FEA) verifiziert. Diese fortschrittliche Technik liefert eine detaillierte Untersuchung des QOC, um sicherzustellen, dass hohe Druck und herausfordernde Betriebsbedingungen standhalten.

F. Zertifizierungsoptionen

QOCs sind mit verschiedenen Zertifizierungsoptionen wie PED, ATEX, CE-Markierung und U-Stamp ausgestattet. Diese Zertifizierungen bieten die Qualität und Sicherheit der QOCs weiter.

III. Zubehörinstrumentierung

A. Zugefügtes Zubehör

QOCs werden in der Regel mit Zubehör wie Davit oder Scharnier und einem Sicherheitswarngerät versorgt. Diese Komponenten verbessern die Sicherheit und Verwendbarkeit des QOC -Systems.

B. Zusätzliches Zubehör

Zusätzliches Zubehör kann einbezogen werden, um die Funktionalität von QOCs weiter zu verbessern. Dies kann ein Schlüsselverriegelungssystem, ein Grenzschalter, ein Einzelpunktbetrieb und eine Schutzabdeckung enthalten.

Iv. Marktpräsenz

A. Globale Versorgung mit Druckbehältern mit EMT QOC

QOCs werden weltweit in zahlreichen Branchen in Druckbehältern anerkannt und verwendet. Ihre immensen Vorteile haben zu einem erheblichen Anstieg ihrer Nachfrage weltweit geführt.

B. Geschichte der QOC -Entwicklung

Die Entwicklung von QOCs wurde durch den Bedarf an größerer Betriebseffizienz und Sicherheit in Branchen unter Verwendung von Druckbehältern angetrieben. Im Laufe der Jahre haben Fortschritte in der Technologie zur Schaffung robusterer und effizienterer QOC -Systeme geführt, die zu ihrer weit verbreiteten Einführung auf dem Markt beitragen.

Häufig gestellte Fragen

Q1. Was ist eine schnelle Schließung (QOC) und was ist ihr Zweck?

A1. Ein Schnellverschluss (QOC) ist ein innovativer Mechanismus für Druckbehälter, um schnelle und sicheren Zugang zu ihrem Innenraum zu gewährleisten. Sein Hauptzweck ist es, die Zeit und den Aufwand für offene und schließende Druckbehälter erheblich zu verkürzen und die Betriebseffizienz und -sicherheit in Branchen zu verbessern, die sich auf solche Schiffe stützen.

Q2. Was sind die Schlüsselkomponenten eines schnellen Verschlusss (QOC)?

A2. Zu den Schlüsselkomponenten eines schnellen Verschlusses (QOC) gehören die Hub-, Abdeck-, Verriegelungssystem- und Dichtdichtung. Jedes dieser Elemente spielt eine entscheidende Rolle bei der Gewährleistung einer robusten und luftdichten Schließung, die zur allgemeinen Sicherheit und Effizienz des Systems beiträgt.

Q3. In welchen Branchen werden häufig Schnellverschlüsse (QOCs) verwendet?

A3. Schnelle Verschlüsse (QOCs) werden in verschiedenen Branchen weit verbreitet, wobei in Sektoren wie Öl und Gas, chemische Verarbeitung und Stromerzeugung eine besondere Prävalenz verwendet wird. Sie sind für ihren Beitrag zur betrieblichen Effizienz und Sicherheit in diesen industriellen Anwendungen bevorzugt.

Q4. Was sind die Hauptvorteile der Verwendung von Schnellverschlüssen (QOCs)?

A4. Die Hauptvorteile von Schnellverschlüssen (QOCs) sind verkürzte Betriebszeit, erhöhte Sicherheit und verbesserte Betriebseffizienz. Durch die Vereinfachung des Öffnungs- und Schließens des Druckbehälters verbessert QOCs die Produktivität des industriellen Betriebs erheblich.

Q5. Welche internationalen Standards entsprechen Schnellverschlüsse (QOCs)?

A5. Quick Closures (QOCs) are designed and manufactured to comply with stringent international standards such as ASME VIII div. 1 & 2 and ISO EN 13445. This compliance ensures the quality, safety, and reliability of the QOC systems.

Rezensionen

Es gibt noch keine Bewertungen.