Beschreibung

I. Einleitung

- Introduction to Corrosion Monitoring Access Systems (CMAS): What they are, why they are needed

Corrosion Monitoring Access Systems (CMAS) are specialized systems designed to allow safe and efficient access for the monitoring and management of corrosion within industrial infrastructure, especially in the oil and gas sector. These systems primarily consist of access fittings, solid or hollow plug assemblies, and protective covers. They enable the insertion and retrieval of corrosion monitoring devices, such as probes or coupons, under full operating pressures. This facilitates the regular assessment of the internal conditions of the infrastructure, providing valuable data on corrosion rates and the effectiveness of corrosion mitigation measures. The need for CMAS arises from the imperative to maintain the integrity of industrial infrastructure and to ensure safe, continuous operation. As corrosion can lead to severe damage, including leaks, equipment failure, and even catastrophic accidents, having a system in place to monitor and manage corrosion is crucial. CMAS allows for the proactive identification of corrosion activity, enabling early intervention and prevention. In this way, CMAS contributes significantly to extending the lifecycle of infrastructure, enhancing safety, reducing the risk of environmental hazards, and ultimately, achieving considerable cost savings. In an era where operational efficiency and sustainability are paramount, the role of Corrosion Monitoring Access Systems becomes increasingly vital. - A brief introduction to corrosion: What it is, why it’s a problem

Corrosion, in its simplest definition, is the degradation of materials under the influence of their environment, most commonly observed as the rusting of metals. This natural process involves the reaction of a metal (or other material) with its environment, leading to a chemical or electrochemical conversion of the material into a more stable form, such as an oxide, hydroxide, or sulfide. The type and rate of corrosion can depend on various factors like the nature of the material, environmental conditions, and the presence of corrosive elements such as oxygen, sulfur, or salts. While corrosion may seem like a minor inconvenience, its implications are far-reaching and significant, particularly in industrial settings. The uncontrolled corrosion of infrastructure, machinery, and equipment can lead to structural failures, accidents, and financial losses due to repair and replacement costs. Furthermore, in industries such as oil and gas, corrosion can lead to leaks, posing severe environmental hazards and safety risks. Hence, understanding, monitoring, and managing corrosion is of utmost importance in maintaining the integrity and reliability of materials and systems in various sectors. - Importance of monitoring and managing corrosion in various industries, particularly in the oil and gas sector

Monitoring and managing corrosion carries significant importance across various industries, with particular emphasis on the oil and gas sector. These sectors are heavily reliant on infrastructures such as pipelines, vessels, and storage tanks, which are often exposed to harsh and corrosive environments, leading to the deterioration of materials over time. Uncontrolled corrosion can compromise the structural integrity of these assets, leading to potential failures, leaks, and even catastrophic accidents. Furthermore, the economic implications of corrosion are profound. The associated costs of corrosion include not only the direct costs of replacing corroded equipment but also the indirect costs of unplanned downtime, loss of product, and environmental contamination. In the oil and gas sector, where the smooth operation of the pipeline network is crucial for productivity and safety, effective corrosion monitoring and management become even more critical. By identifying potential issues early, proactive measures can be taken to prevent corrosion, extend the lifespan of the assets, ensure safety, and ultimately save substantial costs.

II. Detailed Overview of Corrosion Monitoring Access Systems

- Definition and Function of a Corrosion Monitoring Access System

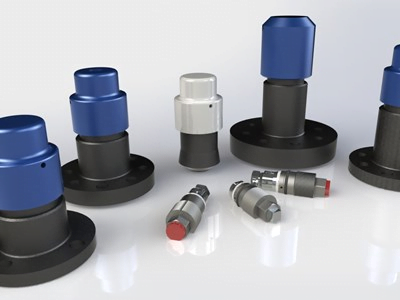

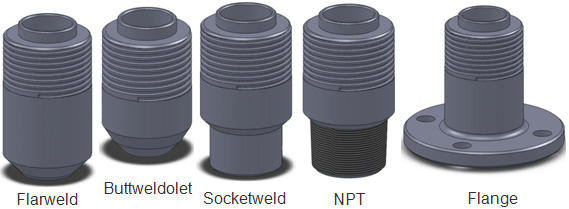

A Corrosion Monitoring Access System (CMAS) is a specialized set-up designed to facilitate the assessment and management of corrosion within industrial infrastructure. It primarily comprises three key components: the access fitting body, which is a specialized pipe fitting permanently affixed to the vessel or pipework; the plug assembly, which serves as a holder for the device being used, and seals the bore of the fitting to contain line pressure; and the protective cover, which safeguards the external threads of the access fitting body. The primary function of a CMAS is to provide a safe and efficient means for the insertion and retrieval of corrosion monitoring instruments, such as probes or coupons, under full operating pressures. This allows for the regular examination of the internal conditions within pipes and vessels, providing invaluable data on corrosion rates and the effectiveness of corrosion mitigation strategies. As such, CMAS plays an instrumental role in maintaining the integrity and safety of industrial operations by allowing for proactive corrosion management. - Components of a CMAS and their rolesCover: This component serves as a protective shield for the external threads of the access fitting body, preserving its integrity and functionality.

Plug Assembly: This is the holder for the device in use. Depending on the specific device employed, one may choose between a solid or hollow plug assembly. This assembly component is screwed into the access fitting body and seals its bore, thereby containing the line pressure.Access Fitting Body: This is a specialized pipe fitting that is permanently affixed to the vessel or pipework of the process plant. Its key role is to enable secure and functional connection within the system.

III. Types of Corrosion Monitoring Access Systems

III. Types of Corrosion Monitoring Access Systems

1. Weight Loss Coupons:

- Vorteile: They are simple, inexpensive, and do not require a power source. They can provide average corrosion rates over a long period and can be used to assess localized corrosion.

- Drawbacks: They only provide intermittent data (not real-time) and require the system to be shut down for retrieval and replacement. The accuracy is dependent on the exposure time, and they provide an average corrosion rate, not immediate changes.

2. Electrical Resistance Probes:

- Vorteile: They can provide continuous, real-time data on corrosion rates and are sensitive to changes in corrosion rates. They can be used in a wide range of environments.

- Drawbacks: They are more expensive than weight loss coupons and require a power source and data logger. They may not be as effective at detecting localized corrosion.

3. Linear Polarization Resistance Probes:

- Vorteile: They provide continuous, real-time data on corrosion rates and are sensitive to changes in corrosion rates. They can measure corrosion under a wide range of conditions.

- Drawbacks: They are relatively complex and expensive, requiring a power source and specialized knowledge to interpret the results. They may not be as effective at detecting localized corrosion.

4. Ultrasonic Testing Devices:

- Vorteile: They provide immediate results and can measure thickness in multiple locations. They are non-invasive and do not require contact with the corrosive medium.

- Drawbacks: They are less accurate at detecting localized corrosion and may require more complex analysis to interpret the results.

5. Corrosion Erosion Monitors:

- Vorteile: They can monitor the loss of material due to both corrosion and erosion, providing comprehensive data. They can use various techniques to suit specific applications.

- Drawbacks: They can be complex and expensive, often requiring a power source, data logger, and specialized knowledge to interpret the results.

IV. Working Principle of Corrosion Monitoring Access Systems

1. Installation of Access Systems: The first step involves installing the access systems onto the infrastructure. This includes an access fitting body that is permanently affixed to the pipe or vessel. It serves as the entry point for the monitoring instruments. A solid or hollow plug is used to seal the fitting and can be removed when needed.

2. Insertion of Monitoring Devices: Once the access system is installed, monitoring devices such as probes or coupons are inserted into the system. The type of monitoring device depends on the specific application and the type of CMAS being used.

3. Data Collection: The monitoring devices collect data by interacting with the environment inside the infrastructure. For example, a weight loss coupon will corrode over time, an electrical resistance probe will measure the increase in electrical resistance due to corrosion, and a linear polarization resistance probe measures the polarization resistance to calculate the corrosion rate.

4. Retrieval of Monitoring Devices: After a certain period, or when real-time data indicates a need, the monitoring devices are retrieved. In the case of weight loss coupons, the corroded coupon is removed, cleaned, and weighed to measure the amount of material loss.

5. Data Analysis: The data gathered by the monitoring devices is analyzed to assess the rate of corrosion, the effectiveness of any corrosion mitigation strategies in place, and to predict future corrosion rates. This data is invaluable in managing the integrity of the infrastructure and planning maintenance or replacement schedules.

6. Proactive Management: Based on the data and analysis, proactive measures can be taken to manage corrosion. This might involve adjusting the environmental conditions (like pH or temperature), changing the material of the infrastructure, or applying a protective coating or corrosion inhibitor.

V. Importance and Benefits of Corrosion Monitoring Access Systems

V. Importance and Benefits of Corrosion Monitoring Access Systems

1. Maintaining Infrastructure Integrity:

Corrosion Monitoring Access Systems (CMAS) play a crucial role in maintaining the integrity of industrial infrastructure. Corrosion, if not properly monitored and managed, can significantly weaken infrastructure such as pipelines and storage tanks, leading to a loss of structural integrity. CMAS provides a way to continuously or periodically assess the rate and extent of corrosion, allowing for timely interventions. By providing insights into the corrosive conditions within the system, CMAS allows organizations to adjust operating conditions or adopt effective corrosion mitigation strategies. This proactive management of corrosion helps maintain the integrity of the infrastructure, reducing the risk of leaks, failures, and potential accidents.

2. Prolonging Equipment Lifespan and Preventing Potential Failures:

By enabling early detection and management of corrosion, CMAS helps in prolonging the lifespan of equipment. Corrosion can lead to the gradual degradation of materials, reducing their functional lifespan. With the data provided by CMAS, organizations can take steps to slow down or halt the corrosion process, thus prolonging the operational lifespan of the equipment. This also aids in preventing potential equipment failures. As corrosion can lead to structural weaknesses, unchecked corrosion can result in equipment breakdowns or even catastrophic failures. By providing timely alerts about increasing corrosion rates, CMAS allows for preventive maintenance or replacement of equipment, thereby avoiding unexpected equipment failures and associated downtime.

3. Cost Savings and Safety Benefits:

The use of CMAS in monitoring and managing corrosion can lead to significant cost savings. Unchecked corrosion can lead to the need for unexpected repairs or replacement of infrastructure, both of which can be costly. By allowing for the proactive management of corrosion, CMAS can extend the lifespan of the infrastructure, reducing replacement costs. In addition, by preventing unexpected equipment failures, CMAS reduces the costs associated with downtime and lost productivity. From a safety perspective, CMAS plays a critical role in preventing accidents that could result from the failure of corroded infrastructure. By maintaining the structural integrity of pipelines, tanks, and vessels, CMAS helps ensure the safety of workers and the environment. Moreover, preventing such incidents also avoids potential legal liabilities and reputational damage, further contributing to cost savings.

VI. Abschluss

Corrosion Monitoring Access System (CMAS) serves as an indispensable tool in the proactive management of corrosion in industrial infrastructure. By providing a means to continuously or periodically assess the rate and extent of corrosion, CMAS plays a critical role in maintaining the structural integrity of equipment such as pipelines and storage tanks. The data provided by these systems allows for timely interventions, helping to mitigate the damaging effects of corrosion and extend the equipment’s operational lifespan.

Through early detection and management of corrosion, CMAS aids in preventing potential equipment failures, minimizing unexpected breakdowns, and the associated downtime. This leads to significant cost savings, as it reduces the need for costly repairs or replacements. Moreover, by maintaining the integrity of the infrastructure, CMAS plays a crucial role in ensuring the safety of workers and the environment, avoiding potential accidents caused by structural failures due to corrosion.

In conclusion, CMAS is instrumental in corrosion management, aiding in the preservation of equipment integrity, prolonging equipment lifespan, preventing potential failures, and promoting cost savings and safety. As such, it stands as a crucial element in the effective operation and maintenance of industrial infrastructure.

Rezensionen

Es gibt noch keine Bewertungen.