Beschreibung

Einführung:

In der Öl- und Gasindustrie ist eine genaue Überwachung der Korrosionsraten von entscheidender Bedeutung, um die Wartungs- und Reparaturkosten im Zusammenhang mit Materialfehlern zu minimieren. Eine kostengünstige und zuverlässige Methode zur Online-Überwachung ist die Verwendung von Korrosions-Gutscheinen. Durch die Messung der Korrosionsrate jedes Jahr können Sie wertvolle Informationen über die Korrosivität des Systems liefern. In diesem Artikel werden wir die Bedeutung von Korrosions -Gutscheinen in der Öl- und Gasindustrie untersuchen und wie sie dazu beitragen können, die Lebensdauer und Integrität von Materialien in einer Vielzahl von Anwendungen zu gewährleisten.

Was sind Korrosionsgutscheine?

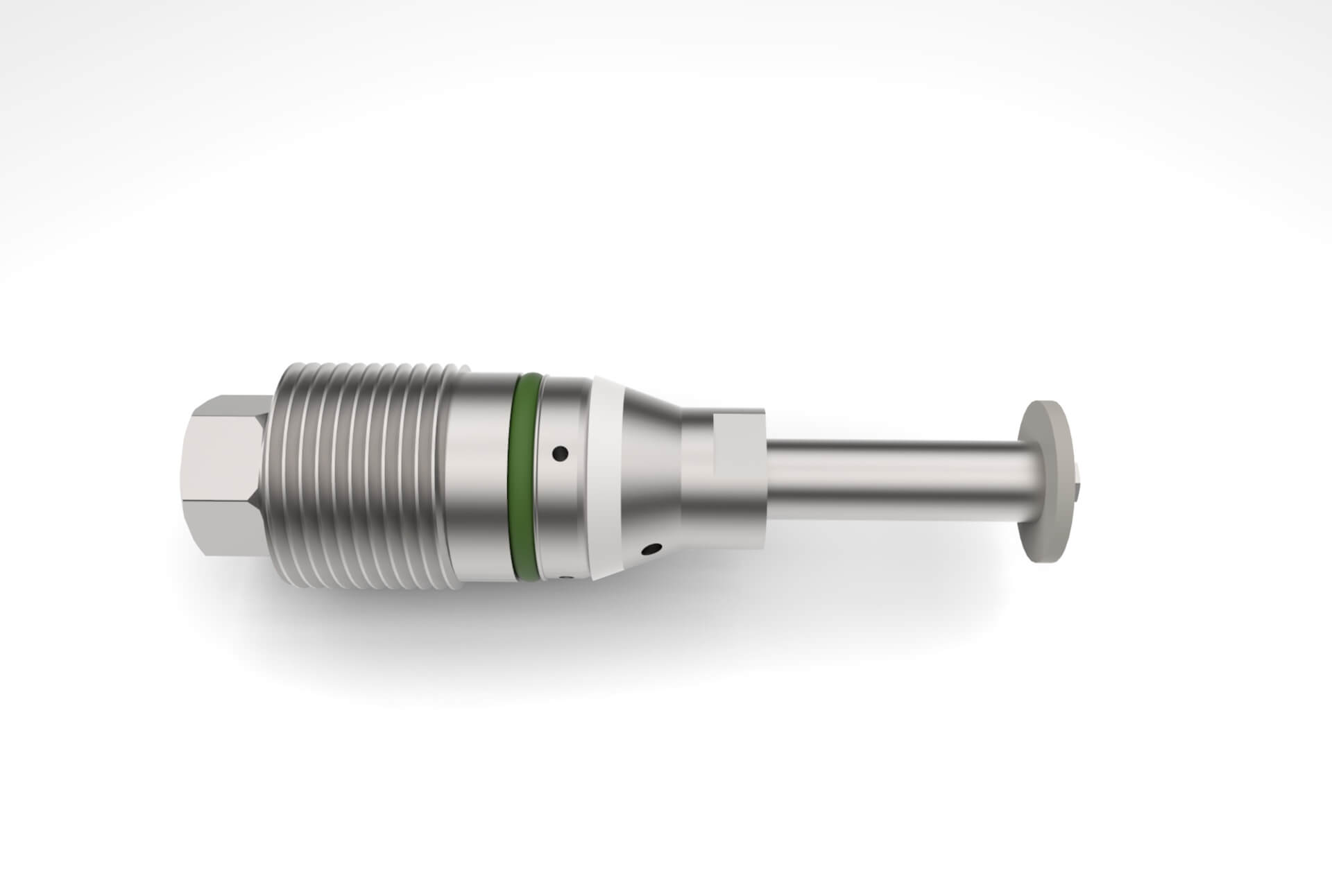

Korrosionsgutscheine werden verwendet, um die Korrosion von Wassersystemen im Laufe der Zeit zu erkennen. Die Gutscheine bestehen aus verschiedenen Materialien, die ursprünglich ohne Korrosion gewogen werden und dann mit ihrem Gewicht verglichen werden, nachdem sie über einen bestimmten Zeitraum Wasser ausgesetzt wurden. Zu den häufigen Expositionszeiten gehören 60, 90 oder 120 Tage. Durch die Überwachung von Veränderungen in der Korrosionsmenge können wichtige Einblicke in Korrosionstrends und die Wirksamkeit chemischer Behandlungsoptionen gewonnen werden.

Vorteile von Korrosionsgutscheinen in der Öl- und Gasindustrie:

Die Verwendung von Korrosionsgutscheinen in der Öl- und Gasindustrie bietet mehrere wichtige Vorteile. Erstens bieten Korrosionsgutscheine eine effektive Möglichkeit, Korrosion zu erkennen und deren Fortschritte zu verfolgen. Durch die Beobachtung von Änderungen des Gelenkgewichts und des Aussehens können die Bediener die Wirksamkeit von Korrosionskontrollmaßnahmen bewerten und fundierte Entscheidungen über Wartung und Reparatur treffen. Korrosionsgutscheine sind ebenfalls relativ einfach zu bedienen, und die Bediener können Korrosion identifizieren, indem sie die Gutscheine vor und nach der Exposition visuell vergleichen.

Effektive Nutzung von Korrosionsgutscheinen:

Um genaue Testergebnisse sicherzustellen, sollten während der Korrosions -Gutscheinanalyse mehrere Variablen berücksichtigt werden. Es sollte darauf geachtet werden, dass das Berühren der Gutscheine mit nackten Händen nicht berührt wird, da das Öl von der Haut die Korrosion fördern und die Testergebnisse beeinflussen kann. Es ist wichtig, während des Testzeitraums einen konstanten Fluss bei einer empfohlenen Geschwindigkeit von 3 bis 5 Fuß pro Sekunde aufrechtzuerhalten. Durchflussraten unter 3 fps können zu einer partikelnden Siedlung des Gutscheins führen und eine Verzerrung einführen, während die Raten von mehr als 5 FPs weichere Metalle untergraben können. Darüber hinaus sollte der Zeitpunkt von Korrosions -Gutscheintests berücksichtigt werden, wodurch die Feder- und Herbstsaison in Komfortkühlsystemen vermieden werden, um einen konsistenten Fluss und realistischere Ergebnisse zu gewährleisten.

Die ordnungsgemäße Installation des Coupon -Racks ist für genaue Testergebnisse von entscheidender Bedeutung. Die Wassertemperatur kann die Korrosionsrate beeinflussen. Die Positionierung des Coupon -Racks entweder vor oder nach der Wärmequelle oder dem Turm kann die gemessenen Korrosionsraten beeinflussen. Die Reihenfolge der Gutscheine im Rack ist wichtig, wobei weniger edle Metalle wie Kohlenstoffstahl stromaufwärts von mehr edlen Metallen wie Kupfer platziert werden, um künstliche Korrosionsraten aufgrund der Überbearbeitung zu verhindern. Es ist auch unerlässlich, Korrosionsgutscheine in Systemen mit Öl- oder Kohlenwasserstoffverschmutzung zu vermeiden, da dies zu künstlich hohen Korrosionsraten führen kann.

Häufige Fehler zu vermeiden:

Um die Wirksamkeit von Korrosions -Gutscheinen zu gewährleisten, ist es wichtig, häufige Fehler zu vermeiden. Ein häufiger Fehler besteht nicht darin, den Systemtyp zu berücksichtigen. Offene Systeme zeigen tendenziell mehr Korrosion und größere Variabilität. Geschlossene Systeme haben in der Regel weniger Korrosion und Variabilität. Es ist auch wichtig, verschiedene Stellen innerhalb des Systems für eine umfassende Diagnose zu testen, anstatt sich auf einen einzelnen Punkt zu konzentrieren. Inkonsistente Überwachung oder Ersatz von Korrosionsplatten kann eine genaue Verfolgung von Lochfraß und Unregelmäßigkeiten auf der inneren Oberfläche verhindern. Es ist wichtig, immer Anweisungen zu befolgen, um zuverlässige und aussagekräftige Daten zu erhalten.

Korrosionstupons in der Öl- und Gasindustrie:

In der Öl- und Gasindustrie spielen Korrosionsgutscheine eine wichtige Rolle bei der Überwachung der Wasserqualität und zur Verhinderung von Materialversagen. Pipelines, Panzer und Geräte sind über einen längeren Zeitraum korrosive Umgebungen ausgesetzt und sind anfällig für Korrosion. Korrosionstickets bieten eine Möglichkeit, Korrosion proaktiv nachzuweisen und die Wirksamkeit von Korrosionskontrollmaßnahmen zu bewerten. Durch die Implementierung von Korrosions -Gutscheinprogrammen können Unternehmen die Integrität ihrer Infrastruktur sicherstellen und die Wartungskosten senken.

Abschluss:

In der Öl- und Gasindustrie sind Korrosionsgutscheine ein wertvolles Instrument zur Überwachung der Korrosionsraten und zur Bewertung der Wirksamkeit von Korrosionskontrollmaßnahmen. Durch die effektive Verwendung von Korrosionstickets können die Bediener korrosion rechtzeitig erkennen, die Behandlungsoptionen bewerten und fundierte Entscheidungen über Wartung und Reparatur treffen, letztendlich die Lebenserwartung von Materialien erweitern und die Kosten senken.

In der Öl- und Gasindustrie stellt Korrosion ein erhebliches Risiko für die Integrität der Infrastruktur dar, und die Verwendung von Korrosionsgutscheinen ist unerlässlich. Sie liefern wertvolle Informationen über die Korrosivität eines Systems und ermöglichen es den Betreibern, Korrosion zu erkennen, die Behandlungsoptionen zu bewerten und fundierte Entscheidungen über Wartung und Reparatur zu treffen.

Die ordnungsgemäße Verwendung der Korrosionsschlacke umfasst die Berücksichtigung von Variablen wie Systemdesign, Durchflussrate, Temperatur und Vermeidung der Kohlenwasserstoffkontamination. Nach den empfohlenen Installations- und Handhabungsverfahren, der Aufrechterhaltung eines konsistenten Prozesses sowie den folgenden Testanweisungen sind entscheidend, um genaue und aussagekräftige Daten zu erhalten. Durch die Vermeidung häufiger Fehler und die Implementierung effektiver Korrosions -Gutscheinprogramme können die Betreiber die Lebensdauer und Integrität ihrer Infrastruktur sicherstellen und gleichzeitig die Wartungs- und Reparaturkosten minimieren.

Insgesamt sind Korrosionsgutscheine ein wichtiges Instrument zur Überwachung der Korrosionsraten in der Öl- und Gasindustrie. Seine Benutzerfreundlichkeit, Effektivität bei der Erkennung von Korrosion und die Fähigkeit zur Bewertung von Behandlungsoptionen machen es zu einem unverzichtbaren Instrument zur Aufrechterhaltung der Integrität der Infrastruktur. Durch die Implementierung von Korrosions -Gutscheinprogrammen und nach Best Practices können die Betreiber effektiv Korrosion verwalten, die Kosten senken und die Lebensdauer ihrer Systeme sicherstellen. Die Verwendung von Korrosionsgutscheinen als Teil einer umfassenden Strategie zur Korrosionsmanagement ist für den langfristigen Erfolg und die Zuverlässigkeit der Öl- und Gasindustrie von entscheidender Bedeutung.

Rezensionen

Es gibt noch keine Bewertungen.