Beschreibung

Einführung in die Pinolenzugangsarmatur mit chemischer Injektion

Einführung in die Pinolenzugangsarmatur mit chemischer Injektion

Quills Access-Fittings spielen eine Schlüsselrolle bei der sicheren und effizienten Zuführung von Chemikalien in das Rohrleitungssystem. Diese Verbindungen bestehen aus Hochleistungsdichtungsmaterialien, die auch bei hohen Drücken Leckagen verhindern und so maximale Betriebssicherheit und Effizienz gewährleisten.

Eines der Hauptmerkmale der Quill Access-Rohrverschraubung ist die integrierte Flüssigkeitseinspritzpumpe. Das System ermöglicht die präzise Einspritzung chemischer Flüssigkeiten in die Rohrleitung durch spezielle Ventile und Verbindungsrohre. Alternativ können die Medien im Rohr problemlos in einen Probenahmebehälter abgesaugt werden, was eine universelle Lösung für eine Vielzahl von Rohrprozessen darstellt.

Wenn Sie weitere Fragen oder Erkenntnisse zu chemischen Injektionsrohren und ihren Anwendungen haben, steht Ihnen unser Team aus Fachleuten gerne zur Verfügung. Verlassen Sie sich auf unser Fachwissen, das Sie durch die Nuancen dieser wichtigen Sanitärkomponente führt.

Die Hochtemperatur-Isoliermaterialien sind:

Teflon: 500″F (260″C) Rulon: 550″F (288″C)

Keramik: 1472″F (800″C)

| Modell | ||||||||||||||||||||||||||||

UND | Zugangsanschluss für chemische Injektionspinolen | |||||||||||||||||||||||||||

| -Code | Stecker | |||||||||||||||||||||||||||

| Pxxx | Typ | Material | Dichtungsmaterial | |||||||||||||||||||||||||

| 0 | Keine Anfrage | 0 | CS | 0 | Keine Anfrage | |||||||||||||||||||||||

| 1 | Hohler Plug-Körper | 1 | 316SS | 3 | DSS | 1 | Viton-O-Ring/PTFE-Primärpackung | |||||||||||||||||||||

| 2 | Massiver Steckerkörper | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Code | Einspritzmutter | |||||||||||||||||||||||||||

| Nxx | Verbindungsgröße | Material | ||||||||||||||||||||||||||

| 0 | d. h. Keine Anfrage | 0 | d.h. CS | |||||||||||||||||||||||||

| 1 | d.h. 1/4″ | 1 | d.h. 316SS | 3 | d.h. DSS | |||||||||||||||||||||||

| 2 | d.h. 1/2″ | 2 | d.h. 316LSS | 4 | d.h. INCONEL | |||||||||||||||||||||||

| – Code | Injektionsschlauch | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Verbindungsgröße | Material | Düse | Liniengröße (x″) | ||||||||||||||||||||||||

| 0 | Keine Anfrage | 0 | CS | 0 | d. h. Keine Anfrage | Die effektivste Injektionsposition ist im Allgemeinen die Mitte des Rohrs | ||||||||||||||||||||||

| 1 | d.h. 1/4″ | 1 | d.h. 316SS | 1 | d.h. Offen | |||||||||||||||||||||||

| 2 | d.h. 1/2″ | 2 | d.h. 316LSS | 2 | d.h. Quill | |||||||||||||||||||||||

| 3 | d.h. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | d.h. INCONEL | |||||||||||||||||||||||||||

| – Code | Nippel und Ventil (oder Endflansch) des T-Stücks | |||||||||||||||||||||||||||

| Danke | Verbindungsgröße | Material | ||||||||||||||||||||||||||

| 0 | d. h. Keine Anfrage | 0 | d.h. CS | |||||||||||||||||||||||||

| 1 | d.h. 1/4″Nippel | A | d.h. 1/4″Nippel und Ventil | 1 | d.h. 316SS | |||||||||||||||||||||||

| 2 | d.h. 1/2″Nippel | B | d.h. 1/2″Nippel und Ventil | 2 | d.h. 316LSS | |||||||||||||||||||||||

| 3 | d.h. 3/4″Nippel | C | d.h. 3/4″Nippel und Ventil | 3 | d.h. D SS | |||||||||||||||||||||||

| 4 | d.h. 1″Nippel | D | d.h. 1″Nippel und Ventil | 4 | d.h. INCONEL | |||||||||||||||||||||||

| 5 | d.h. 1/4″Flansch | e | d.h. 1/4″Nippelendflansch | |||||||||||||||||||||||||

| 6 | d.h. 1/2″Flansch | F | d.h. 1/2″Nippelendflansch | |||||||||||||||||||||||||

| 7 | d.h. 3/4″Flansch | G | d.h. 3/4″Nippelendflansch | |||||||||||||||||||||||||

| 8 | d.h. 1″Flansch | H | d.h. 1″Nippelendflansch | |||||||||||||||||||||||||

P221: z.B. Massiver Stopfenkörper aus 316LSS Viton O-Ring und PTFE-Primärpackung N12: z. B. ist die Anschlussgröße der Einspritzmutter 1/4″ und das Material ist 316LSS. S122: z.B. Injektion Die Rohranschlussgröße beträgt 1/4 Zoll und das Material ist 316LSS. Der Düsentyp ist Pinolen L4″: Für 4″ Rohr. T22: Die Größe des T-Stück-Nippels beträgt 1/2 Zoll, das Nippelmaterial ist 316LSS | ||||||||||||||||||||||||||||

Chemische Injektionskomponenten sind ein wichtiges Werkzeug für die Öl- und Gasindustrie. Betreiber verwenden diese Komponenten, um Chemikalien in Hochdruckrohre zu injizieren, die Produktionsflüssigkeiten, Meerwasser und eine Vielzahl anderer Medien transportieren. Dieser Prozess dient mehreren Zwecken, beispielsweise der Verbesserung der Betriebseffizienz der zugehörigen Verarbeitungsausrüstung, dem Schutz der Ausrüstung und der Bohrlochkopfrohre sowie der Verlängerung der Lebensdauer der Ausrüstung.

Chemische Injektionsrohre werden in der weltweiten Ölförderungs- und -verarbeitungsindustrie häufig eingesetzt. Bei der Ölfeldförderung injizieren chemische Injektionspumpensysteme hauptsächlich Methanol oder Ethylenglykol in die Flüssigkeit vor dem Düsenverteiler. This action prevents the fluid from forming frozen hydrates due to a drop in pressure. At the same time, the reliability of the surface test system and the upper and lower pressure drop range of the nozzle are improved, so that the oil (gas) well can resume normal operation.

Name | Zugangsanschluss für chemische Injektionspinolen | |

| Material | Edelstahl 304, Edelstahl 316, DSS F51, Kohlenstoffstahl A105N und auch Inconel 625 | |

| Betriebstemperatur | -20~+120℃ | |

| Funktionen | Erstens einfach zu bedienen | |

| Second, long life and high accuracy | ||

| At last, low cost and high efficiency | ||

| Zahlung | TT/LC | |

| Vorteile | First, lightweight and flexible | |

| Second, excellent injection efficiency | ||

| Endlich genaue Standortverfolgung |

This ensures safety. In the process industry, we use chemical injection systems. This allows liquid chemicals to be precisely injected into the reinjected or injected liquid at either high or low pressure. Es gibt viele Arten chemischer Wirkstoffe, die in die Lösung injiziert werden, darunter in der Regel Methanol, Ethylenglykol, Konservierungsmittel und Desoxidationsmittel. Es gibt auch Bohrflüssigkeitszusätze (Natronlauge und flüssige Polymere) und Entschäumer. Chemische Injektionspumpensysteme können auch zur quantitativen Zufuhr von Ausgangsstoffen zu Hochdruckreaktoren eingesetzt werden.

Das chemische Kraftstoffeinspritzpumpensystem besteht aus drei Teilen: Ultrahochdruckhydraulik, Mechanik und Antriebsluft. Der hydraulische Abschnitt stellt eine Ultrahochdruckquelle für das chemische Injektionssystem bereit. Der Antriebsluftteil treibt das gesamte System an. Der maximale Arbeitsdruck des Chemikalieneinspritzsystems beträgt 1050 bar. Der Hochspannungskreis ist mit Filter- und Überspannungsschutzgeräten ausgestattet. Mit Ölstands- und Druckanzeigefunktion. Es hat auch die Funktion, den Druck zu halten und Material abzuleiten. Der Antriebsluftteil treibt das gesamte System an. Der maximale Betriebsdruck des Antriebsluftkreises beträgt 10bar. Der Antriebsluftkreislauf ist mit Filter- und Überspannungsschutzvorrichtungen ausgestattet. Mit Druckanzeigefunktion. Es verfügt auch über eine Druckregulierungsfunktion.

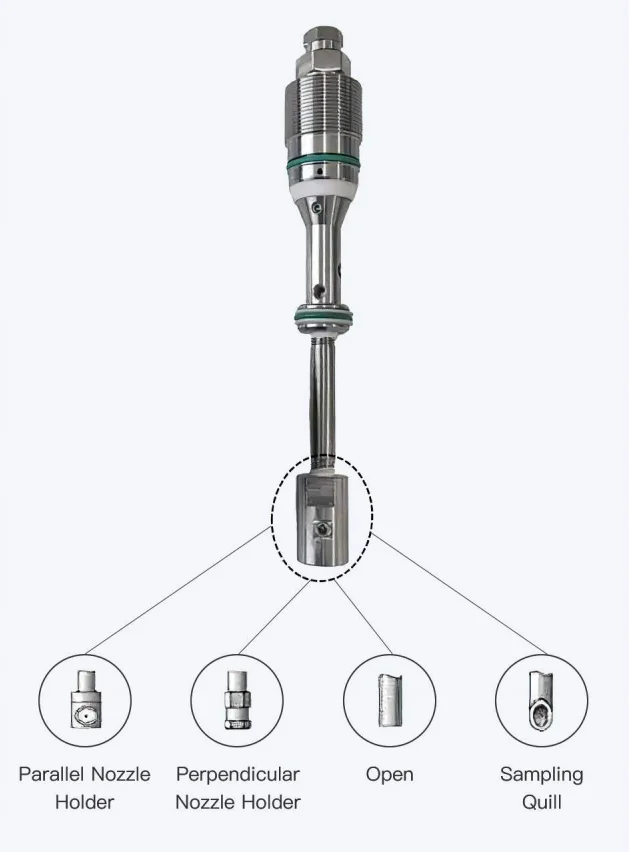

Einführung in die Düsentypen in chemischen Injektionsnadeln

Die chemische Injektionspinole ist mit vier verschiedenen Düsentypen ausgestattet, die jeweils für eine bestimmte Funktion und einen bestimmten Zweck ausgelegt sind. Wenn Sie diese verschiedenen Düsentypen verstehen, können Sie Ihren Einsatz in einer Vielzahl von Anwendungen optimieren. Jeder Düsentyp hat seine eigenen einzigartigen Vorteile und Anwendungen und erweitert so den vielseitigen Einsatz von Federrohren für die chemische Injektion in der Öl- und Gasindustrie.

Paralleldüsen: Wie der Name schon sagt, sind Paralleldüsen so konzipiert, dass sie parallel zur Strömungsrichtung im Rohr verlaufen. Dies ist die ideale Möglichkeit, Chemikalien einzuspritzen und sofort mit dem Rohrleitungsfluss zu verschmelzen.

Vertikale Düsen: Im Gegensatz zu Paralleldüsen stehen Vertikaldüsen im rechten Winkel zur Rohrströmung. Dies ermöglicht eine stärker verteilte Chemikalieninjektion und erhöht den Rohranteil der Mischung.

Düse öffnen: Dieser Düsentyp weist am Ende der Feder keine Begrenzungsstruktur auf. Durch die offene Düse können Chemikalien ungehindert und ungehindert in das Rohr fließen, wodurch eine großvolumige Injektion gewährleistet wird.

Probenahmefeder: Der Probenahmestift wird verwendet, um Proben aus dem Rohr zu entnehmen, anstatt Chemikalien in das Rohr zu injizieren. This is essential for testing and quality control as it allows operators to monitor and evaluate the chemical composition in the pipeline.

Unser Service

Unsere Dienste

We offer a wide range of chemical injection pipe fittings to meet specific requirements. Please do not hesitate to contact us to find the solution that best suits your needs.

In order to reflect the high quality of our products, we provide our customers with the option to request samples.

We pride ourselves on providing prompt service to our customers. Our team is ready to provide immediate feedback and address your queries.

We strive to provide the fastest delivery time to ensure that you receive your order in a timely manner. Our online support is available 24 hours a day, 7 days a week.

Packaging & Delivery

Unsere Produkte sind in KOFFER verpackt, die folgende Vorteile bieten:

- Sie sind leicht, zeichnen sich durch klare Linien aus, isolieren und zeichnen sich durch eine hohe Festigkeit ohne Verformungsneigung aus.

- Sie machen eine Begasung überflüssig und machen den Versandprozess effizienter.

Unser Ziel ist es, qualitativ hochwertige Zugangsanschlüsse für chemische Injektionsnadeln zeitnah und effizient zu liefern, wobei die Kundenzufriedenheit jederzeit im Vordergrund steht.

Einführung in die Pinolenzugangsarmatur mit chemischer Injektion

Einführung in die Pinolenzugangsarmatur mit chemischer Injektion

Rezensionen

Es gibt noch keine Bewertungen.