Description

Introduction

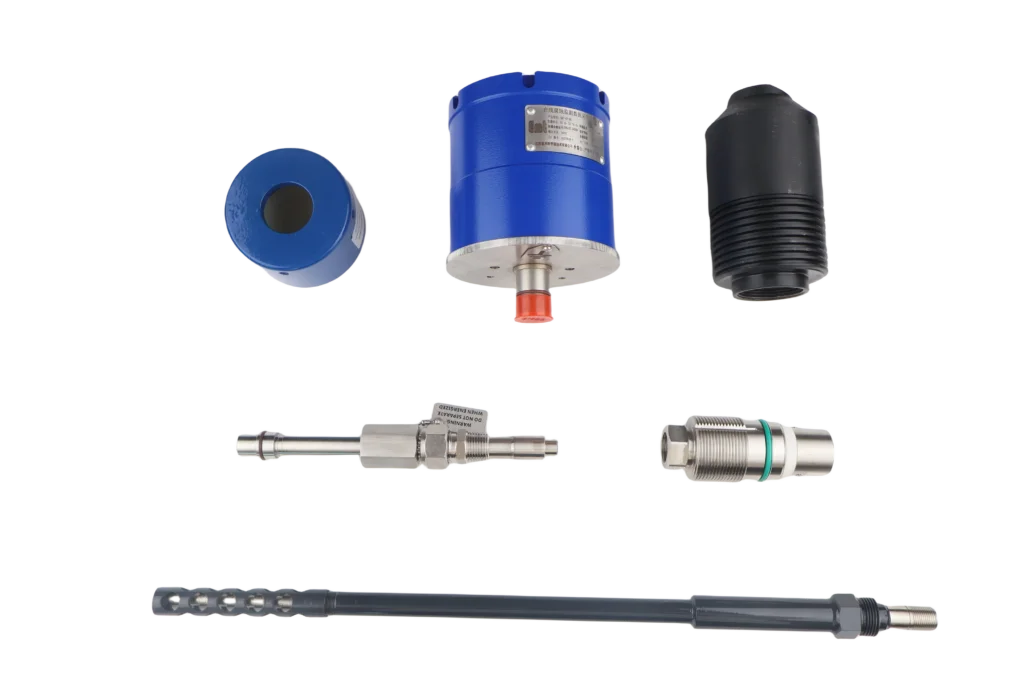

Electric Resistance (ER) Probe measurement is a sophisticated detection methodology premised on the quantification of metal loss. The technique gauges the rate of corrosion by continuously tracking alterations in the probe’s resistance value. The versatility of this method allows for its application across diverse environments, irrespective of the nature of the process. The ER corrosion probe’s sensitive elements adopt various designs, including ring, tube, ring-tube, flat head, and strip forms, typically crafted from 316 stainless steel. However, the material choice for the sensitive element can be customized to suit distinct monitoring environments.

Historical Development

The genesis of foreign resistance probe corrosion monitoring technology dates back to the 1950s. The probe functioned as a sensitive element, exposed to the environment of interest. Over time, refinements in the probe structure bolstered its resolution and sensitivity. Significant advancements were achieved by researchers in Europe and the United States. The 1960s saw an upsurge of patented technologies related to resistance probe corrosion monitoring in the United States, marking the technology’s readiness for industrial implementation. The 1970s witnessed the maturation of the technology, characterized by enhanced sensitivity and precision, deeming it suitable for monitoring low-corrosion rate environments such as atmospheric corrosion. However, technological limitations and other factors led to a plateau in measurement accuracy at the micron level during the 1980s and 1990s.

Monitoring Principle

Electric Resistance (ER) Probe Technology is a corrosion monitoring method that measures resistance change in a metal test piece during corrosion. As corrosion advances, the conductive metal sheet’s thickness diminishes, thereby increasing its resistance, considering that the corrosion products, predominantly metal oxides, are generally non-conductive. The initial resistance of the metal test piece is computed based on the formula R=ρl/A, where ρ denotes electrical conductivity, R symbolizes resistance, A represents the cross-sectional area, and l stands for the length of the metal test piece. ER Probe technology finds application in various media, such as liquid (electrolyte or non-electrolyte) and gas. The technology is characterized by simple operation, ease of maintenance, and straightforward data analysis, along with real-time corrosion data acquisition and transmission. Given its high reliability and economic efficiency, it finds extensive application across industries like oil and gas production, pipelines, the chemical industry, cultural relic preservation, and power generation.

Features of Electric Resistance Probe

- Operates effectively under any environmental conditions.

- Compatible with various standard installation interfaces available on the market (ER probe, weightless coupon).

- Uninterrupted continuous monitoring despite changes in site conditions

- Real-time monitoring of pitting corrosion, general corrosion, and crevice corrosion rates

- Capability to display pitting corrosion alarms.

- Provides signals indicating the lifespan of the ER probe.

Development and Application of Electric Resistance Probe Corrosion Monitoring Technology

Corrosion is a costly global problem. The United States, for example, loses $276 billion annually to corrosion, or about 3.1% of its GDP. In other countries, the total annual cost of corrosion is equivalent to 5% of GDP. In addition, safety incidents due to deterioration of material properties can lead to catastrophic consequences.

Such accidents are usually caused by a natural gas leak caused by corrosion in a pipeline that seeps into a main sewer. Major safety accidents caused by corrosion also occur from time to time. For example, Sinopec Qingdao Donghuang oil pipeline leak and explosion in 2013, mainly due to pipeline corrosion failure.

As the most commonly used base material in industries such as production and construction, metals are inevitably subject to corrosion in their working environment. In order to reduce the huge economic losses and prevent the occurrence of major safety accidents, it is necessary to monitor the corrosion process of materials under the conditions of use. Corrosion monitoring is a means to obtain the information of corrosion change, and is an important part of corrosion technology and corrosion protection.

Resistance probe corrosion monitoring technology is a corrosion detection method to measure the change of metal resistance during corrosion. It has the ability to provide real-time monitoring of continuous corrosion data, simple working principle, wide applicability, and plays an important role in material corrosion monitoring.

Future Developments and Innovations in ER Probes

The realm of Electric Resistance (ER) Probe technology is ripe for innovative advancement, particularly in the areas of data analysis, material composition, and integration with emergent technologies. The sophistication of data analytics tools is increasing at a rapid pace, and with it comes the potential for more nuanced interpretation of ER probe data. Machine learning algorithms could be leveraged to predict corrosion trends, identify unusual patterns, and trigger timely alerts, thereby preventing costly damage or equipment failure.

Material science also holds substantial promise for the evolution of ER probes. Research into more corrosion-resistant materials or alloys could enhance the lifespan and reliability of the probes. Furthermore, the development of nanotechnology might allow for the design of even smaller and more sensitive probes, enabling the detection of corrosion at its earlier stages.

Finally, the integration of ER probes with Internet of Things (IoT) and artificial intelligence (AI) technologies could revolutionize corrosion monitoring. IoT connectivity would allow for remote monitoring of probes installed in hard-to-reach or hazardous locations, while AI could automate the analysis of vast amounts of data, turning it into actionable insights.

Environmental Impact and Safety Considerations

Electromagnetic radiation detectors play a vital role in helping industry comply with environmental regulations and enhance workplace safety. By providing real-time data on corrosion, these tools enable early detection and mitigation of potential equipment failures that could lead to harmful leaks or spills. This proactive approach not only protects the environment, but also protects employees from dangerous situations.

However, the use of ER probes is not without environmental and safety considerations. For example, the manufacturing process of the probe should be carefully checked for any potential environmental impacts, such as waste generation or energy consumption. In terms of security, installing and maintaining ER probes in some environments can be risky and requires adherence to strict security protocols.

Conclusion

In short, resistance (ER) probe technology is a cornerstone in the fight against corrosion, a common problem faced by countless industries. This advanced technology provides real-time, actionable data that allows timely intervention to prevent equipment failures, protect the environment, and ensure worker safety.

Looking ahead, the future of alien probes is bright and exciting. The convergence of data analytics, advanced materials, and emerging technologies such as the Internet of Things and artificial intelligence promises to usher in a new era of corrosion monitoring. As the industry continues to develop and face new challenges, the role of ER probes will undoubtedly become more important. We therefore have a responsibility to continue to invest in and advance this critical technology.”

Reviews

There are no reviews yet.