Description

The EMT online corrosion monitoring system operates on its own battery and doesn’t require a cable connection on-site. Corrosion data can be wirelessly imported into our device. Operators can choose the frequency of daily monitoring or select a specific time interval for monitoring. After downloading the EMT software, corrosion monitoring data can be accessed with a single click. The computer automatically calculates the corrosion rate based on the corrosion data and the corrosion rate calculation formula. The pipeline corrosion rate is considered normal if it is less than 0.25 mm per year. If it exceeds this range, safeguards should be implemented to protect the pipeline. This corrosion monitoring device consists of two parts: the collector and the corrosion probe. The collector is an explosion-proof, enclosed structure designed for use in the petrochemical industry.

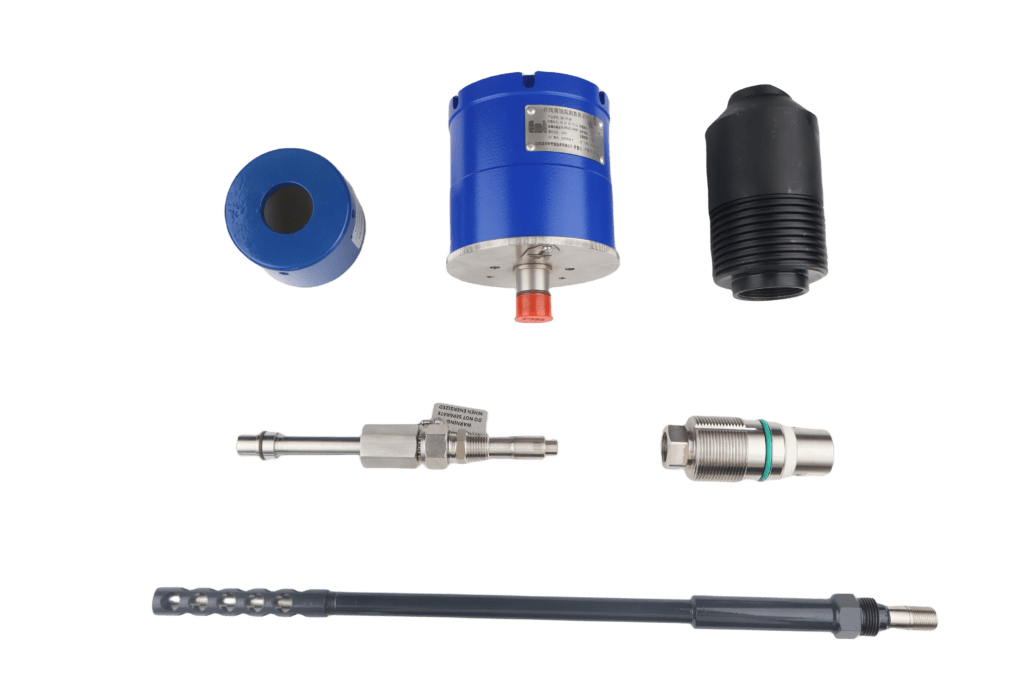

The Components of the Online Corrosion Monitoring System

The Online Corrosion Monitoring System is comprised of several key components, each playing a crucial role in its operation and effectiveness:

- Project Cover: This component is designed to shield the probe from any external force, preventing it from popping out. It ensures the probe’s stability and safety, allowing it to function optimally.

- Collector: The remote data collection is composed of modules such as power supply, measurement and control logic, and data transmission. After configuration based on the ID provided at the time of manufacture, it can enter into normal operating status. It is a critical part of the system, as it is responsible for gathering corrosion data from the pipeline. This data is pivotal in understanding the rate and extent of corrosion within the pipeline, helping professionals make informed decisions about maintenance and repair strategies.

- Welded Base: The welded base is a sturdy component that is securely attached to the pipeline. It serves as a foundation for the system, providing a stable platform for the other components and ensuring their proper alignment and functionality.

- Connection Pole: This component serves as a connecting link between the corrosion probe and the collector. It secures the position of the probe, ensuring it maintains contact with the pipeline for accurate corrosion data collection.

- Corrosion Probe: The corrosion probe is the heart of the system. It simulates the corrosion process of the pipeline, providing real-time data on the rate and extent of corrosion. Its readings are vital inputs for predictive maintenance strategies and lifespan estimations of the pipeline.

- Handheld Computer: It can download the corrosion data by connecting the Bluetooth. Open the software of EMT, then you can download the corrosion monitoring data.

Main Parameters

| Range: | 0 ~ 261144 probe life units; |

| Impedance range of the probe-sensitive element: | 1~50mΩ |

| Resolution: | Typical value: 1nm. (The total thickness of a typical probe-sensitive element is 20mil, with a lifespan of 10mil.) |

| Repeatability: | ±?% of full scale |

| Power Supply: | 24VDC power supply/Lithium battery; |

| Current Consumption: | 12mA@24VDC/1~12mA@8.4V; |

| Communications: | RS485 two-wire, 2400 baud rate/2.4G, LORA, 4G/5G or 4-20mA |

| RS485 Address: | 0 ~ 31 |

| Environmental Temperature: | -40℃~ +70℃ |

| Enclosure Protection Level: | IP 65 |

| Maximum Collection Rate: | Once per minute |

| Minimum Collection Rate: | Once at any interval |

| Hazardous Area Certification: | Ex d IICT4 Gb |

Applications of the Online Corrosion Monitoring System

The Online Corrosion Monitoring System has a wide range of applications across various industries where monitoring and controlling corrosion is crucial. Here are some key applications:

- Oil and Gas Industry: These systems can monitor corrosion in pipelines, storage tanks, and processing equipment, helping to prevent leaks or failures due to corrosion.

- Chemical Industry: In chemical processing plants, these systems can monitor corrosion rates in pipes and tanks to ensure the integrity of the infrastructure and prevent contamination.

- Water Treatment Plants: The systems can be used to monitor corrosion in water pipes and storage tanks to prevent leaks and maintain water quality.

- Power Generation: In power plants, including nuclear facilities, these systems can be used to monitor corrosion in boilers, cooling systems, and other equipment.

- Marine Industry: On ships and offshore platforms, these systems can help monitor and control corrosion due to the harsh, salty environment.

- Pharmaceutical Industry: These systems can be used to monitor corrosion in process equipment and piping to ensure product purity and safety.

- Food and Beverage Industry: These systems can monitor corrosion in processing equipment to prevent contamination and maintain product quality.

Working Principle

The Online Corrosion Monitoring System operates based on the principle of measuring alterations in the resistance value of the corrosion probe’s sensitive elements, which correspond to the thinning due to corrosion. The materials of these sensitive elements are selected to match those of the pipeline or equipment.

Over a specified period, the system accumulates data on the corrosion-induced thinning of these sensitive elements. This data is then used to calculate the corrosion rate, which is representative of the corrosion rate of the pipeline or equipment. In this way, the system facilitates real-time, online monitoring of the corrosion status of pipelines and equipment.

Signal Transmission

The Remote Data Collection adopts two modes of signal transmission:

- Two forms of wired connections, where the power supply is a DC24V provided on-site, capable of outputting either an RS485 signal or a 4-20mA current.

- A wireless mode via Bluetooth, powered by its own lithium battery. The collected data is stored internally and can be downloaded using an explosion-proof Bluetooth device.

The Technical Merits

This system exhibits a weak correlation with the medium, thereby enabling it to measure corrosion in varying states of matter including liquid, gas, and a mixed phase of liquid and gas.

Conclusion

The EMT Online Corrosion Monitoring System is a critical tool in several industries where the durability and integrity of metal infrastructure are paramount. It effectively measures and monitors corrosion in pipelines and equipment, providing valuable, real-time data that aids in predictive maintenance and decision-making processes.

This system is equipped with a robust array of components like the corrosion probe, collector, connection pole, and protective project cover, all designed to ensure accurate data collection and secure operation. The system’s ability to function in wired or wireless modes — including Bluetooth — adds to its versatility, making it adaptable to various operational conditions.

Moreover, the EMT system’s technical proficiency lies in its ability to measure corrosion across different mediums, including liquid, gas, and liquid-gas mixtures, demonstrating its wide applicability.

The EMT Online Corrosion Monitoring System is a powerful tool, providing industries with a real-time, accurate, and efficient method to monitor, control, and manage the pervasive issue of corrosion. Its use can lead to significant cost savings, improved safety, and extended lifespan of vital infrastructure.

Reviews

There are no reviews yet.